- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

RE-201D RE-301 RE-501 rotary evaporator is a rotary evaporator sold directly by our company. Cheap price, convenient operation, stable quality, economical and practical. Laboratory rotary evaporator is an important equipment for separation, crystallization, drying and purification in the fields of biopharmaceutical, medicine, chemistry and chemical industry.

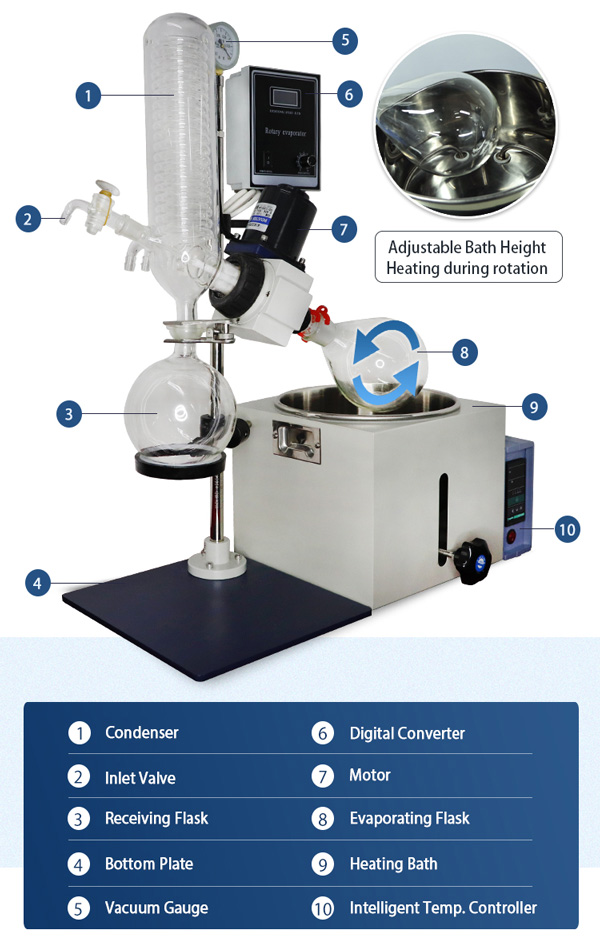

The laboratory rotary evaporator consists of a condenser, a feed valve, a feed pipe, a clamp, a receiving bottle, a support ring, a stainless steel column, a stainless steel bottom plate, a vacuum gauge, a speed regulator control box, a rotary head, a rotary bottle, a bath Composed of a pot and a heating controller, the following are the functions of the main components of the laboratory rotary evaporator:

1. The rotating motor drives the evaporating flask containing the sample through the rotation of the motor;

2. The evaporating tube, the evaporating tube has two functions, firstly, it acts as a rotating support shaft for the sample, and secondly, the sample is sucked out by the vacuum system through the evaporating tube;

3. Vacuum system, used to reduce the air pressure of the rotary evaporator system;

4. Fluid heating pot, usually the sample is heated with water;

5. Condensation tube, use double serpentine condensation or other condensing agents such as dry ice and acetone to condense samples;

6. Condensate the sample collection bottle, and the sample enters the collection bottle after cooling.

The laboratory rotary evaporator consists of three parts: mechanical part, glass part and constant temperature water bath. Some parts have been assembled in place when leaving the factory, and the installation of the whole machine is very convenient. The specific installation steps are as follows:

1. Place the stainless steel bottom plate, pole, nut, bracket, and vacuum gauge on the operating table stably.

2. Install the pole:

Assemble the bracket and the vacuum gauge on the pole; remove a nut at the lower end of the stainless steel bracket, tighten the other nut on the stand, and penetrate the stainless steel bottom plate, then tighten it with the removed nut, and make the front of the vacuum gauge Facing the installer. Place the rack flat on the work bench.

3. Install the host:

Connect the main unit to the base of the machine head, tilt it to the right about 45 degrees, and lock the screws on the frame.

4. Install the glass part:

·Put the glass shaft into the host, install the PTFE gasket and flange, and tighten the screws.

·Fix the flange end of the condenser on the machine head, and make the condenser vertical up and down, and the connectors of the condenser face backward.

·Connect the PTFE tube with the feeding valve, and then install it to the left end of the condenser.

·Dock the collecting bottle with the lower port of the condenser, and clamp it with the bottle clamp.

·Fix the bottle support ring on the stainless steel pole with screws, and adjust it to an appropriate height to stabilize the collection bottle.

·Put the rotating bottle on the right end of the rotating shaft and clamp it with the bottle clamp.

·Put the water bath under the rotating bottle, and add 2/3 of water or heat conduction oil to the pot.

5. Fix the controller on the handle with screws, and plug in the five-pin plug of the motor.

6. Connection method of supporting equipment: connect the vacuum pump or laboratory vacuum switch with a vacuum tube at the exhaust port of the condenser;

1. Check the instrument carefully before use, whether the glass bottle is damaged, whether the interfaces are consistent, and handle with care.

2. Wipe each interface with a soft cloth (you can replace it with a napkin), and then apply a little vacuum grease. The vacuum grease must be covered after use to prevent dust from entering.

3. The connectors should not be screwed too tightly, but should be loosened regularly to avoid the connectors being seized by long-term locking.

4. Turn on the power switch first, and then let the machine run from slow to fast. When stopping, make the machine stop, and then turn off the switch.

5. The PTFE switches everywhere should not be tightened too hard, as it is easy to damage the glass.

6. After each use, you must use a soft cloth to wipe off all kinds of oil stains, stains, and solvent residues left on the surface of the machine, and keep it clean.

7. Unscrew each PTFE switch after stopping the machine, and the PTFE piston will be deformed if it is still in the working state for a long time.

8. Clean the sealing ring regularly. The method is: take off the sealing ring, check whether there is dirt on the shaft, wipe it clean with a soft cloth, then apply a little vacuum grease, and reinstall it to keep the shaft and the sealing ring smooth.

9. The electrical part must not enter the water, and it is strictly forbidden to be damp.

1. Beautiful appearance, small and light, top-rotating seal, using PTFE and fluorine rubber composite sealing structure, good sealing performance, strong corrosion resistance, good vacuum.

2. Manual lifting, high stability, knob button adjustment, digital display, convenient operation.

3.1°c-100°c temperature adjustment, 0-120 (r/m) speed adjustment, to meet various needs of laboratory instruments.

4. The motor and circuit adopt imported products, and can be upgraded to explosion-proof, safer and longer service life.

Heating at constant temperature, rotating under negative pressure to form a film, and at the same time, the solvent is evaporated, condensed and recovered. It is especially suitable for the concentration, crystallization, separation and recovery of heat-sensitive materials.

It is generally used for separation, crystallization, drying, purification and other operations in biopharmaceutical, pharmaceutical, chemical, chemical and other industries.

We recommend choosing low-temperature coolant circulating pumps and circulating water vacuum pumps. You can also contact us, and we will make suggestions according to your needs.

Our company's rotary evaporator is all made of high borosilicate glass, acid and alkali resistance, high temperature resistance, high transparency, wear resistance, smooth surface and easy to clean.

The material contained in the rotary evaporator is generally one-half of the rotary bottle, or a little more than one-half.

Model | RE-201D | RE-301 | RE-501 |

Evaporating Flask(L) | 2 | 3 | 5 |

Receiving Flask(L) | 1 | 2 | 3 |

Rotating Motor(W) | 40(Stepless speed regulation) | ||

Rotating Speed(R/min) | 0-120 | ||

Water(Oil)Bath Power(W) | 1200 | 1500 | |

Temp Control Mode/Range | Intelligent digital/RT-399℃ | ||

Temp Resolution | ±2℃ | ||

Evaporation Rate(L/H2O) | ≥1 | ≥1.5 | ≥1.5 |

Max. Vacuum Degree | <133pa(1.33mbar,1Torr,0.098Mpa) | ||

Lifting Height(mm) | 0-150 | 0-120 | 0-120 |

Water Bath Size | Φ24*15 | Φ26*15 | Φ28*17 |

Condenser | Vertical with charge pipe, large condenser,evaporating pipe | ||

Lifting Mode | Oil bath Manual Lifting | ||

Voltage | 220V/ 50 HZ | ||

Sealing Mode | PTFE,fluoro rubber sealing | ||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap