- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Feature:

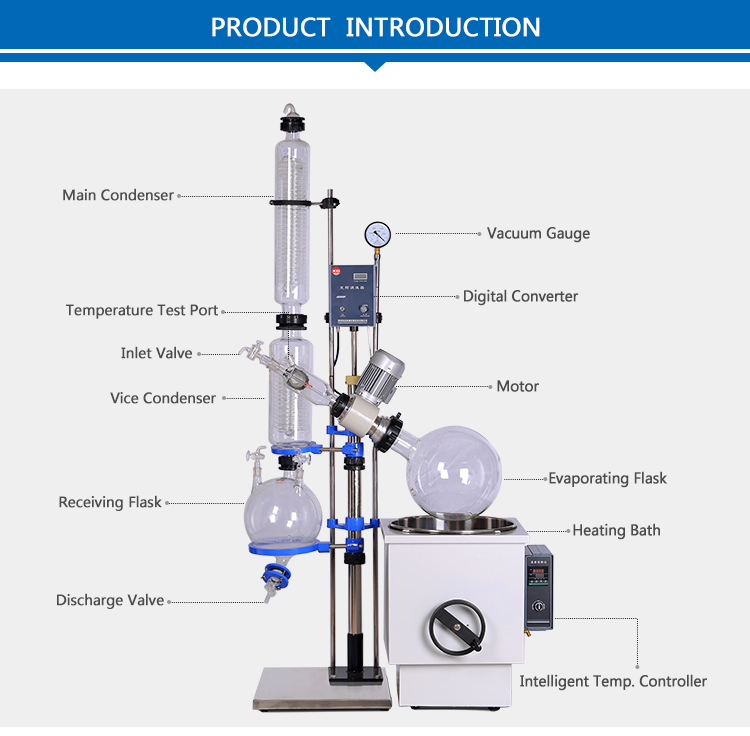

RE-1002 RE-2002 RE-5002 rotovaps are the rotovap machine independently researched and developed by our company. It has a main and a secondary condenser, which can be customized. It is cheap, simple to operate, stable in quality, economical and practical, and is a biopharmaceutical It is an important equipment for separation, crystallization, drying, purification, recycling and other operations in the fields of medicine, chemistry and chemical engineering.

Advantage:

1. ce, iso certified product patent certificate

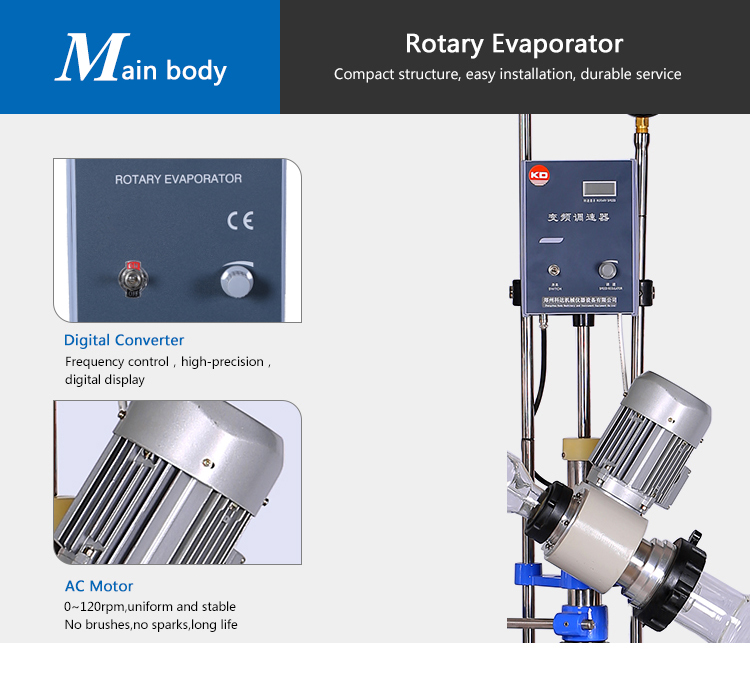

2. Manual lifting, high stability, knob button adjustment, digital display, convenient operation.

3. The main and auxiliary double condenser design, the material recovery rate is high, the recovery rate can reach 95%.

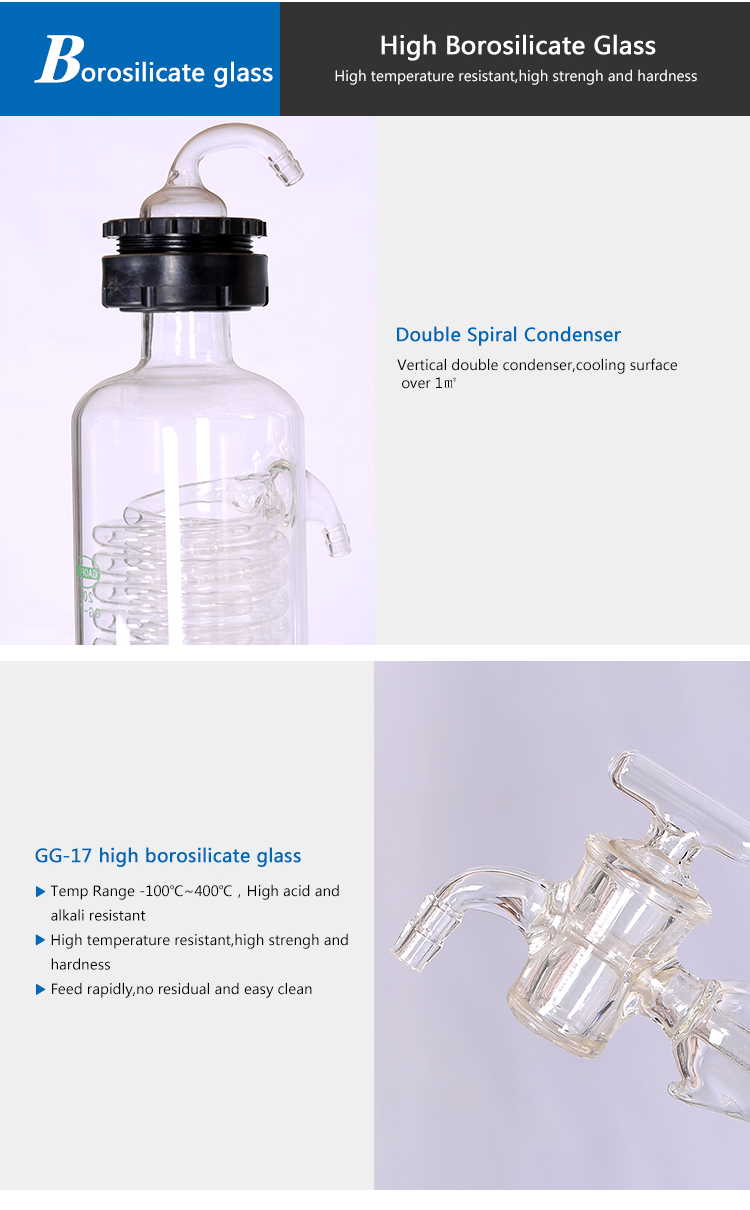

4. The bracket is made of 304 stainless steel, which is strong and durable. The rotating bottle, receiving bottle and condenser are made of high-quality borosilicate glass, which is not easy to break.

5. The rotating main engine starts stably, the speed is 0-120 (r/m), the motor and circuit adopt imported products, and can be upgraded to explosion-proof, safer and longer service life.

6. The sealing part adopts the principle of flange sealing, which can maintain high vacuum.

After sale:

Free maintenance for life.

Technical engineers can receive overseas training.

Remote technical consultation.

Video guide installation.

Free replacement of some accessories.

Grouped equipment:

RE-1002 rotovap:DLSB-20/30Low temperature coolant circulation pump and SHZ-C circulating water vacuum pump.

RE-2002 rotovap:DLSB-30/30Low temperature coolant circulation pump and SHZ-C circulating water vacuum pump.

RE-5002 rotovap:DLSB-50/30Low temperature coolant circulation pump and SHZ-C circulating water vacuum pump.

FAQ:

1. What is the working principle of the rotary evaporator?

It is heated under constant temperature and rotated under negative pressure to form a film, and at the same time, the solvent is evaporated and condensed for recovery.It is especially suitable for concentration, crystallization, separation and recovery of heat-sensitive materials.

2. What are the uses of the rotary evaporator?

It is generally used for separation, crystallization, drying, purification and other operations in biopharmaceutical, pharmaceutical, chemical and chemical industries.

3. What are the steps to use the rotary evaporator?

After adjusting the position of the rotary evaporator and the bath, turn on the vacuum. The material can be sucked into the rotating bottle with a hose on the feeding port. Turn on the low-temperature coolant circulation pump. The water bath must be energized after adding the medium. Turn on the control switch and adjust the knob to the optimal speed to recover the solvent. Turn off the vacuum pump, turn on the switch to deflate, and take out the dissolved coal in the collection bottle.

4. What are the precautions when using the rotary evaporator?

When the set temperature of the low-temperature cooling circulation pump is lower than 0 degrees, the cooling medium cannot use water. Contact our technicians to replace the appropriate medium (such as glycol), and inject 1/2 volume of the medium into the heating pot to ensure that it is submerged 1/2 of the evaporating flask is enough.

5. How to choose a cryopump for rotary evaporator?

We recommend choosing a low-temperature coolant circulating pump, which has the advantages of energy saving, water saving, anti-fouling and anti-scaling. According to your needs, we can provide various types of circulating water vacuum pumps.

6. What is the power supply of the rotary evaporator?

The power supply of our rotary evaporator is generally 220V50HZ and 110V60HZ

Model | RE-1002 | RE-2002 | RE-5002 |

Evaporating Flask(L) | 10 | 20 | 50 |

Receiving Flask(L) | 5 | 10 | 20 |

Rotating Motor(W) | 180W | ||

Rotating Speed(R/MIN) | 0-120 | 0-120 | 0-90 |

Water(Oil) Bath Power(W) | 3000 | 4500 | 7000 |

Temperature Control Range | RT-399℃ | ||

Temperature Fluctuation(℃) | ±1℃

| ||

Evaporation Rate(H2O) | >3L/h | ≥5L/h | ≥9L/h |

Condenser | Vertical Double Condenser | ||

Lifting Mode | Water(Oil) Bath Mannal Lifting | ||

Lifing Height(mm) | 0~220 | ||

Voltage | 220V50HZ | 220V/50HZ | 380V50HZ |

Sealing Mode | PTFE,Fluoro Rubber Sealing | ||

Note | Customized configuration is available | ||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap