- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

DZF-6210 Vacuum drying oven with pump is widely used in biochemistry, chemical and pharmaceutical, medical and health, agricultural scientific research, environmental protection and other research and application fields, for powder drying, baking and disinfection and sterilization of various glass containers. It is especially suitable for fast and efficient drying of heat-sensitive, easily decomposed, easily oxidized substances and complex composition items.

The vacuum environment greatly reduces the boiling point of the liquid that needs to be expelled, so vacuum drying can be easily applied to heat-sensitive substances;

For samples that are not easy to dry, such as powder or granular samples, vacuum drying can effectively shorten the drying time;

Vacuum drying is used for various mechanical parts or other porous samples with complex structures after cleaning, and no participating substances are left after complete drying;

It is safer to use, under vacuum or inert conditions, completely eliminates the possibility of oxides being thermally exploded;

·Compared with ordinary drying relying on air circulation, powdery samples will not be blown or moved by flowing air.

1. The large-screen LCD screen of the vacuum drying oven with a pump can display multiple sets of data on one screen, and the menu-style operation interface is easy to understand and easy to operate.

2. The aluminum shelf of the vacuum drying box with a pump is stamped by a special process, which has high temperature non-oxidation and fast heat conduction. Minimize heat loss

3. The rectangular parallelepiped studio makes the utilization rate of the effective volume large, and the microcomputer temperature controller ensures accurate and reliable temperature control.

4. Toughened, bulletproof double-layer glass door to observe the objects in the working room at a glance, and can fill the interior with inert gas.

5. The tightness of the box door can be adjusted freely by the user. The integrally formed silicone rubber door seal ensures high vacuum in the box.

6. The working room is made of stainless steel plate, the box shell is made of high-quality cold-rolled steel plate, and the surface is electrostatically sprayed.

7. Storage, heating, testing and drying are carried out in an environment without oxygen or filled with inert gas, which will not cause oxidation.

8. The heating element is located on the inner partition of the box, and the heating time is shortened by 50% compared with the traditional vacuum oven.

Rotary vane vacuum pump: The rotary vane vacuum pump can remove the dry gas in the sealed container, and if it is equipped with a gas ballast device, it can also remove a certain amount of condensable gas. But it is not suitable for pumping gas with high oxygen content, corrosive to metal, chemical reaction to pump oil and dust particles.

1. Open the door, put the items to be processed on the shelf inside the box, close and tighten the door. And close the purge valve, open the pumping vacuum valve, turn on the vacuum pump to pump air, so that the vacuum degree in the box is

2. Turn on the power supply of the vacuum drying oven with pump, insert the power plug into the power socket, and put the power switch on the panel in the "on" position. At this time, the instrument will display a digital display, indicating that the equipment is in working state.

3. Set the temperature in the box you need by operating the temperature controller.

4. The vacuum drying box with a pump starts to work, and the temperature in the box gradually reaches the set value. After the required drying treatment time, the treatment work is completed.

5. Turn off the power, and when the temperature inside the box is close to the ambient temperature, open the vent valve to release the vacuum inside the box. Open the door and take out the items.

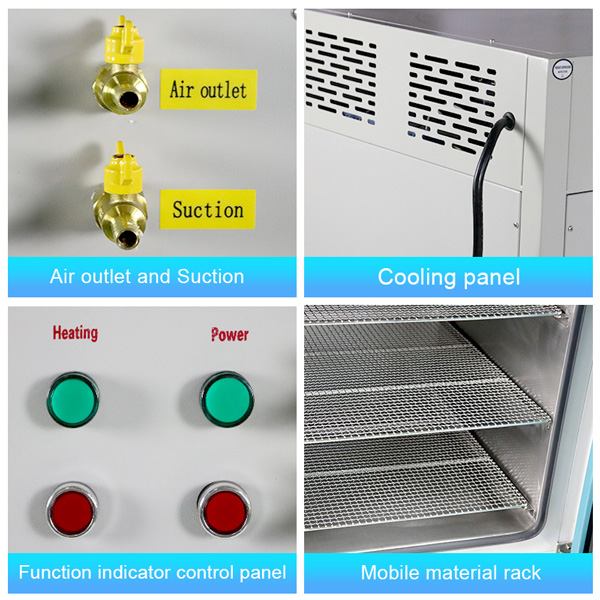

Intelligent liquid crystal temperature controller, inert gas inlet valve, vacuum gauge, cabinet.

On the one hand, it provides heat to the inside of the box, on the other hand, it evacuates, and the moisture in the material is sucked away by the vacuum pump to achieve the purpose of drying.

The laboratory vacuum drying oven produced by our company can be equipped with rotary vane vacuum pumps and diaphragm pumps. Please contact us for specific specifications.

You can contact us, we will provide quotations for different models according to your needs.

Model | DZF-6210 |

Power Supply(V/Hz) | 220/50 |

Shell Material | Spray-paint Anti-corrosion |

Liner Material | 304 Stainless Steel |

Temp. Range(°C) | RT+10~200(250) |

Max. Vacuum Degree(Mpa) | 0.098 |

Temp. Stability(°C) | ±1.0 |

Temp. Analysis(°C) | 0.1 |

Working Temp.(°C) | +5~40 |

Input Power (W) | 2060 |

Chamber Capacity (L) | 215 |

Inner Dimension (W*D*H,mm) | 560*600*640 |

Overall Dimension (W*D*H,mm) | 720*820*1750 |

Shelves (Pcs) | 3 |

Time Range(min) | 1~9999 |

Optional Configuration | Explosion-proof |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap