- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

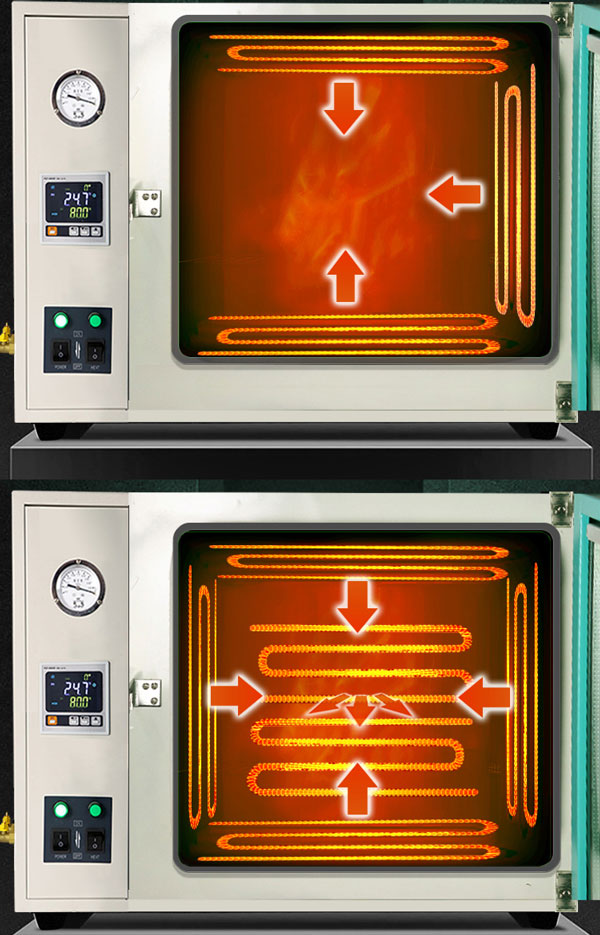

The laboratory vacuum drying oven is especially suitable for rapid and efficient drying of heat-sensitive, easily decomposed, easily oxidized substances and complex components.

1. The square studio maximizes the effective area. Toughened, bulletproof double-layer glass doors to observe objects in the studio at a glance.

2. The tightness of the door of the laboratory vacuum drying box can be adjusted, and the integrally formed silicone rubber door seal ensures high vacuum in the box.

3. Microcomputer intelligent controller, with dual digital display and PID self-tuning function for setting and measuring temperature, accurate and reliable temperature control.

4. The heating power ratio of the laboratory vacuum drying oven can be adjusted arbitrarily to ensure that the low-end temperature control has no disadvantages of temperature overshoot.

5. It is especially suitable for drying heat-sensitive and oxidizable substances that are easily decomposed, and can also be filled with inert gas into the working room to quickly dry specific items. (If you need to fill inert gas protection items, please contact the manufacturer)

6. The laboratory vacuum drying oven can be equipped with a SMS monitoring and alarm system. If the user is not on site and the equipment fails, the system collects the fault signal in time and sends it to the mobile phone of the designated recipient through SMS to ensure timely troubleshooting, resume the experiment, and avoid accidental losses.

· The vacuum environment greatly reduces the boiling point of the liquid that needs to be expelled, so vacuum drying can be easily applied to heat-sensitive substances;

· For samples that are not easy to dry, such as powder or granular samples, using vacuum drying can effectively shorten the drying time;

· Vacuum drying is used for various mechanical parts or other porous samples with complex structures after cleaning, and no participating substances are left after complete drying;

· It is safer to use, under vacuum or inert conditions, completely eliminates the possibility of thermal explosion of oxides;

· Compared with ordinary drying relying on air circulation, powdery samples will not be blown or moved by flowing air.

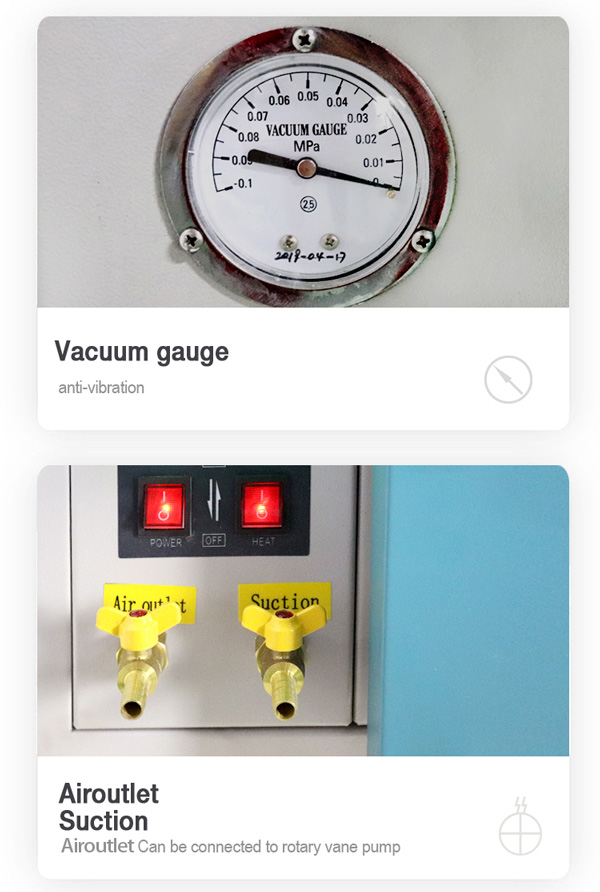

Diaphragm vacuum pump

Rotary Vane Vacuum Pump

The vacuum drying box should be kept clean frequently, and the door glass should be wiped with a soft cotton cloth. When not in use for a long time, neutral grease or vaseline should be applied to the electroplated parts to prevent corrosion, and a plastic film dust cover should be placed in a dry room. , so as not to affect the use of electrical equipment due to moisture.

Do not open the side door unless necessary to avoid damage to the electrical system. The shell of the vacuum drying oven must be effectively grounded to ensure safe use. When the vacuum box does not need to pump air continuously, the vacuum valve should be closed before powering the vacuum pump, otherwise the vacuum pump oil will be poured into the box. Vacuum pump oil should be replaced frequently.

Temperature: 5 ~ 40 ℃, relative humidity: ≤85%RH, no strong vibration and corrosive gas around.

Within the heat-resistant range of the material, the higher the temperature, the better the drying effect.

Model | DZF-6090 |

Power Supply(V/Hz) | 220/50 |

Shell Material | Spray-paint Anti-corrosion |

Liner Material | 304 Stainless Steel |

Temp. Range(°C) | RT+10~200(250) |

Max. Vacuum Degree(Mpa) | 0.098 |

Temp. Stability(°C) | ±1.0 |

Temp. Analysis(°C) | 0.1 |

Working Temp.(°C) | +5~40 |

Input Power (W) | 2000 |

Chamber Capacity (L) | 90 |

Inner Dimension (W*D*H,mm) | 450*450*450 |

Overall Dimension (W*D*H,mm) | 610*680*710 |

Shelves (Pcs) | 2 |

Time Range(min) | 1~9999 |

Optional Configuration | Explosion-proof |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap