- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

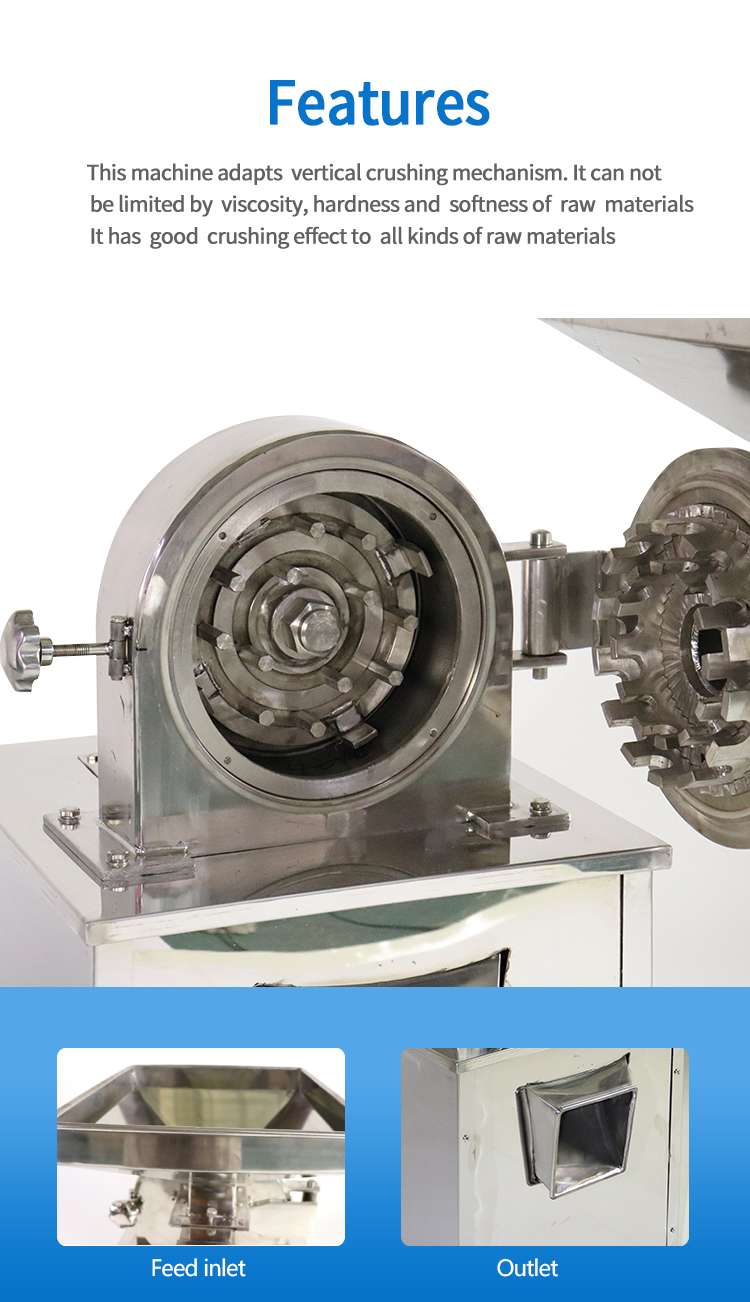

Coarse crusher is suitable for pharmaceutical, chemical, metallurgical, food, construction and other industries. It can process hard and hard materials, including plastics, copper wire, Chinese herbal medicine, rubber, etc. it can also be used as the supporting equipment for the previous process of micro grinder and ultra-fine grinder.

1. The coarse crusher is designed and manufactured according to GMP standard, and the whole machine is made of stainless steel, with simple structure and convenient cleaning.

2. The appearance of the machine is beautiful, the color matching is coordinated, and the painting is firm.

3. The front and back walls of the crushing chamber adopt double-layer sound insulation with low noise.

4. Overload protection device and power supply interlock protection system.

5. The coarse crusher has the advantages of simple structure, low investment cost and good crushing effect. It is especially suitable for hard materials that are difficult to crush.

6. High safety performance, and reduce the overflow of dust when feeding.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

What is the working principle of the coarse crusher?

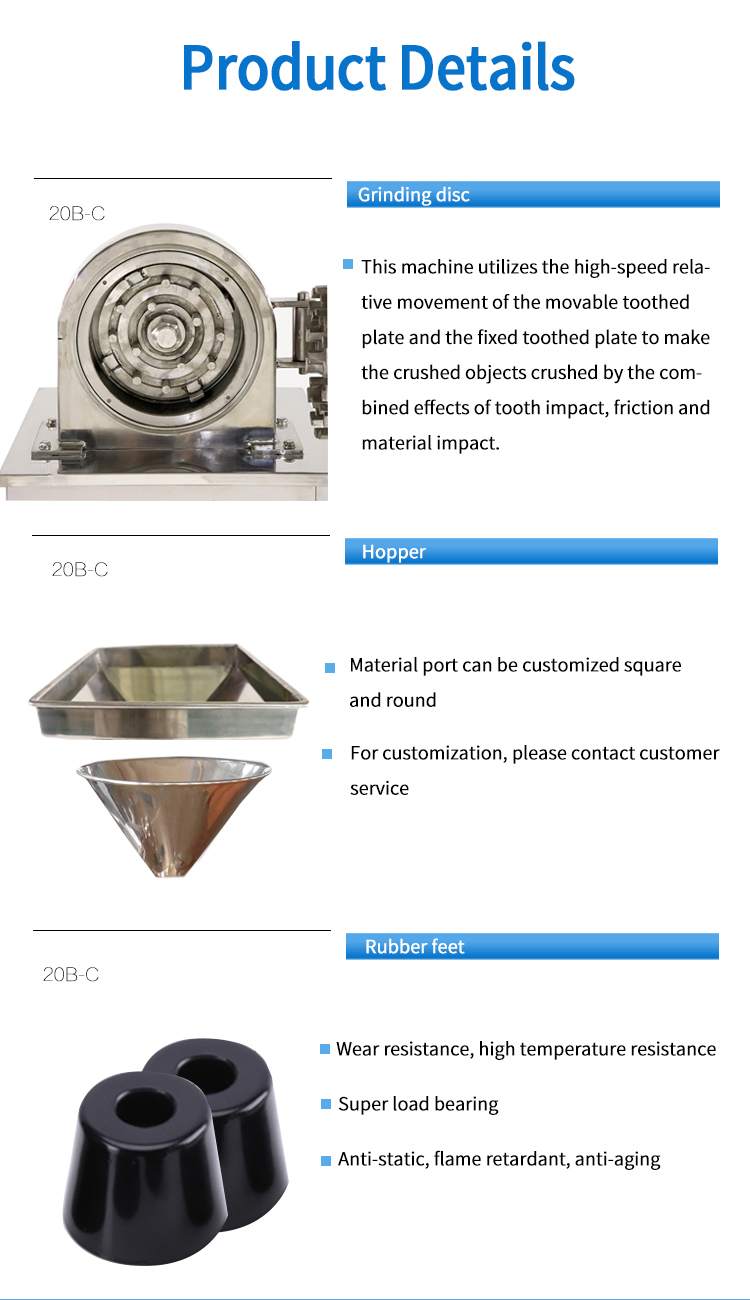

The material is sent into the crushing chamber by the feeding hopper. Under the impact of the blade and the knife, the rotating knife and the fixed knife are sheared and crushed at the same time. Due to the effect of the rotating centrifugal force, the material automatically flows out from the outlet.

What is the purpose of the coarse crusher?

The coarse crusher is mainly used in medicine, food, chemical industry, dye, pigment, auxiliary agent, diatomite and other industries. It is a horizontal tilting structure, which consists of base, motor, crushing chamber, cover and feeding bucket. The hopper and cover can be tilted at a certain angle, which is convenient for removing the storage and repair in the crushing room. It can be used to process hard and hard materials, and it can also be used as a supporting equipment for the previous process of micro crushing. It is not limited by the viscosity, hardness, softness and fiber of materials, and can achieve good crushing effect for any material.

Model | 20B-C | 30B-C | 40B-C | 60B-C |

Productive capacity (kg/h) | 60-150 | 100-300 | 160-800 | 500-1500 |

Revolution of spindle (r/min) | 4500 | 3800 | 3400 | 2800 |

Size of fed material (mm) | 6 | 10 | 12 | 15 |

Grinding size(mesh) | 60-120 | 60-120 | 60-120 | 60-120 |

Power of motor(kw) | 4 | 5.5 | 11 | 15 |

Fan power (kw) | 1.5 | 1.5 | 1.5 | 2.2 |

Overall dimension (L*W*H) | 1100x600x1650 | 1200x650x1650 | 1350x700x1700 | 1550x1000x1750 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap