- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

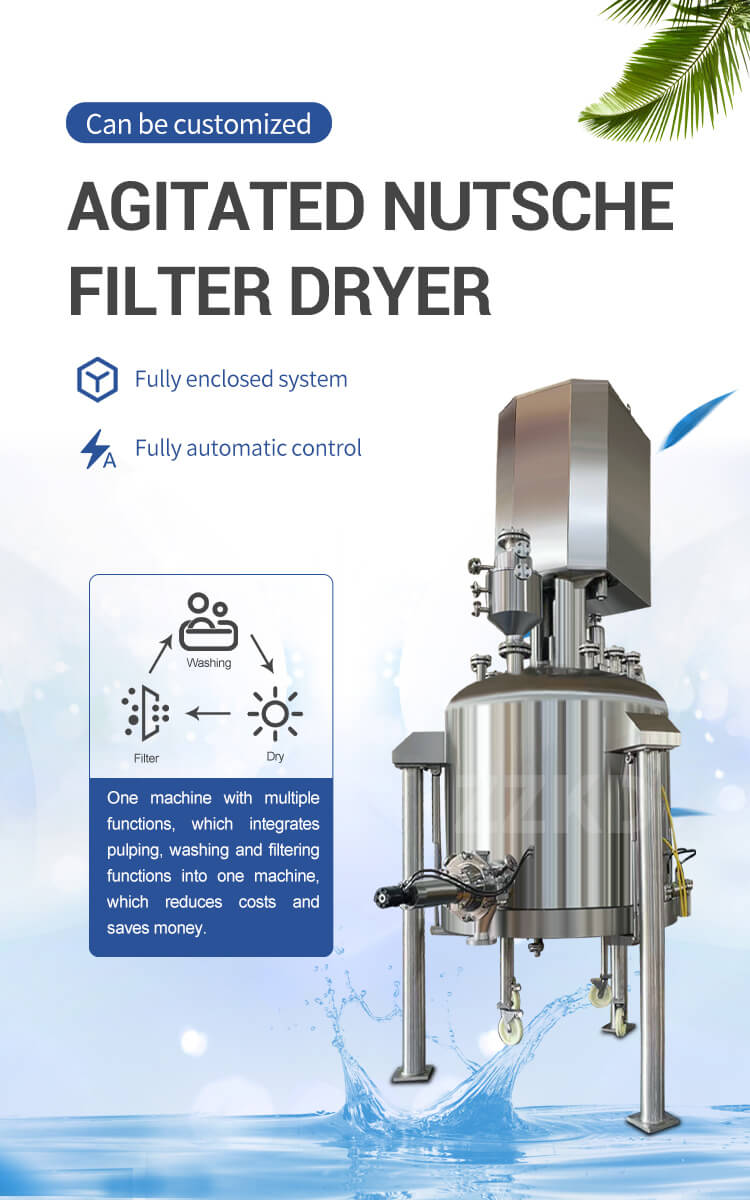

Solid-liquid separation is a crucial process in various industries, including pharmaceuticals, chemicals, and food processing. The efficient removal of solid particles from liquid suspensions is essential for product quality and process optimization. In this regard, the agitated nutsche filter dryer (ANFD) has emerged as a versatile and highly effective solution. This article explores the advantages and applications of the agitated nutsche filter dryer, highlighting its effectiveness in solid-liquid separation processes.

The agitated nutsche filter dryer offers several significant advantages over traditional separation techniques, such as centrifugation or vacuum filtration. Here are some key benefits:

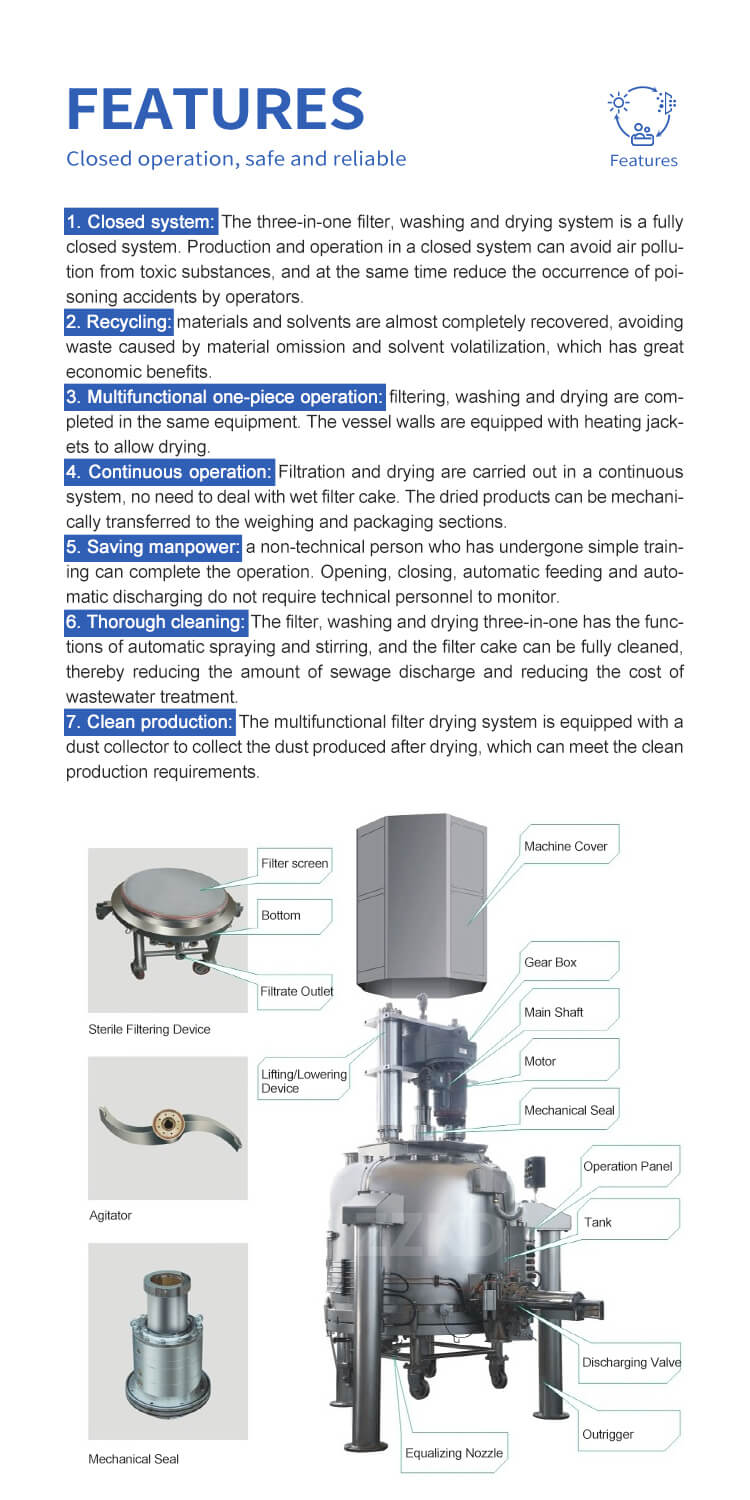

1. Simultaneous Operations: The ANFD combines filtration, washing, and drying operations into a single unit, thereby reducing the need for separate equipment and minimizing process steps. This integration streamlines the production process and saves time and resources.

2. Efficient Solid-Liquid Separation: The ANFD employs a filter medium, typically a stainless-steel screen or filter cloth, which ensures effective separation of solids from liquids. The agitated vessel enhances filtration by promoting better cake formation and preventing clogging, resulting in higher filtration rates and improved product quality.

3. Agitation for Enhanced Performance: The agitator in the ANFD facilitates uniform mixing, preventing sedimentation and promoting the formation of a homogenous filter cake. Agitation also helps in efficient washing of the cake, ensuring thorough removal of impurities and contaminants.

4. Drying Capability: The ANFD allows for effective drying of the filtered product by applying heat and vacuum. This feature eliminates the need for separate drying equipment, reducing operational costs and maximizing productivity.

The versatility of the agitated nutsche filter dryer makes it suitable for a wide range of applications across various industries. Some common applications include:

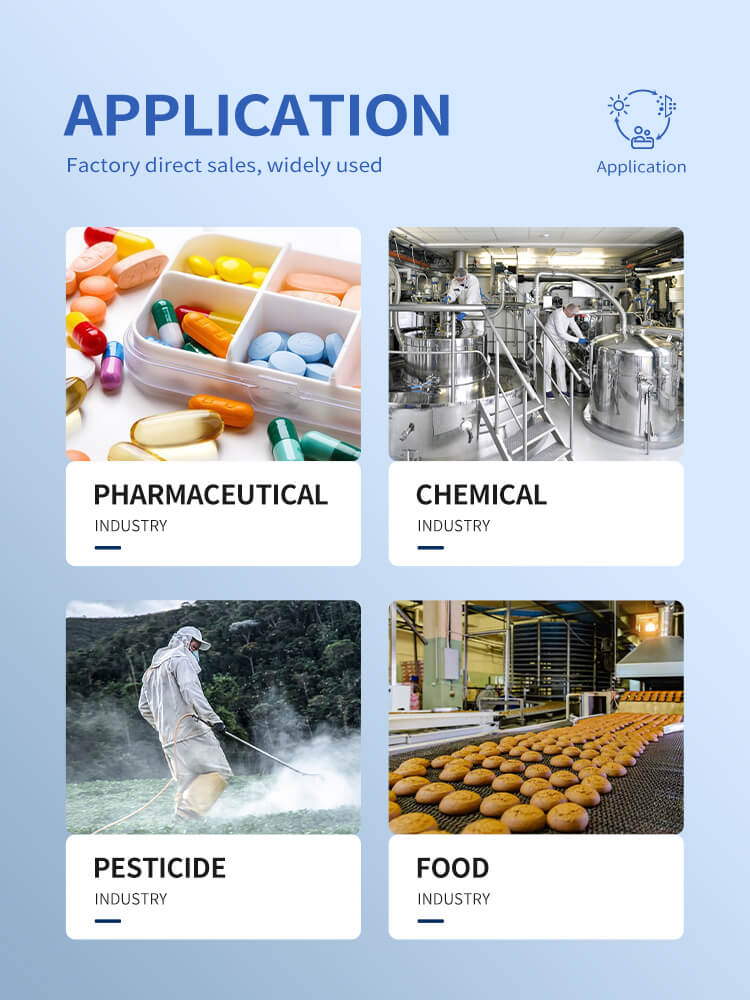

1. Pharmaceuticals: ANFDs are widely used in pharmaceutical manufacturing processes, such as API (Active Pharmaceutical Ingredient) production, isolation of intermediates, and purification of pharmaceutical compounds. The ANFD ensures high-quality separation and drying, meeting the stringent requirements of the pharmaceutical industry.

2. Chemicals: ANFDs find extensive application in the chemical industry for the separation and purification of chemical compounds. They are commonly used in processes involving organic synthesis, catalyst recovery, and removal of impurities from chemical solutions.

3. Food Processing: ANFDs play a vital role in the food processing industry, particularly in the production of edible oils, fruit juices, and beverages. The ANFD enables efficient separation and filtration of solids from liquids, ensuring the purity and clarity of the final product.

An excellent example of the application of an agitated nutsche filter dryer is the purification of antibiotics. During antibiotic production, impurities and by-products must be removed to meet stringent quality standards. The ANFD enables efficient separation of solid particles, ensuring the purity and efficacy of the antibiotic.

In this case, the agitated nutsche filter dryer's simultaneous filtration, washing, and drying capabilities simplify the purification process. The filter medium effectively removes unwanted impurities, while the agitator prevents clogging and ensures a homogenous filter cake. The drying function of the ANFD then allows for the removal of moisture, resulting in a high-quality, purified antibiotic product.

The agitated nutsche filter dryer offers numerous advantages for solid-liquid separation processes. Its ability to combine filtration, washing, and drying operations in a single unit streamlines production, saves time and resources, and ensures high-quality separation. With applications in pharmaceuticals, chemicals, and food processing, the agitated nutsche filter dryer proves to be a versatile and efficient solution for a wide range of industries.

Q: What is an agitated nutsche filter dryer?

A: An agitated nutsche filter dryer (ANFD) is a specialized equipment used for solid-liquid separation processes. It combines the functions of filtration, washing, and drying into a single unit, offering an efficient and convenient solution for various industries.

Q: How does an agitated nutsche filter dryer work?

A: The ANFD consists of a cylindrical vessel with an agitator and a filter medium, such as a stainless-steel screen or filter cloth. The slurry or suspension is introduced into the vessel, and the agitator ensures uniform mixing and formation of a filter cake. The liquid is separated from the solid particles through the filter medium, while the agitator prevents clogging. After filtration, the cake can be washed and subsequently dried using heat and vacuum.

Q: What are the advantages of using an agitated nutsche filter dryer?

A: The advantages of an ANFD include simultaneous operations of filtration, washing, and drying, which streamline the production process. The agitator promotes efficient solid-liquid separation by enhancing filtration rates and preventing clogging. Additionally, the ANFD eliminates the need for separate equipment for each process, saving time, resources, and operational costs.

Q: In which industries is the agitated nutsche filter dryer commonly used?

A: The ANFD finds applications in various industries, including pharmaceuticals, chemicals, and food processing. It is extensively used in pharmaceutical manufacturing for the production and purification of active pharmaceutical ingredients (APIs) and intermediates. In the chemical industry, it is employed for catalyst recovery and removal of impurities. The ANFD also plays a crucial role in food processing, particularly in the production of edible oils, fruit juices, and beverages.

Q: What are the key considerations when using an agitated nutsche filter dryer?

A: When using an ANFD, it is important to consider the compatibility of the materials with the equipment, ensuring that the vessel, agitator, and filter medium are suitable for the process requirements. The selection of the filter medium is crucial to achieve efficient solid-liquid separation. Additionally, proper maintenance and cleaning of the ANFD are essential to ensure its longevity and optimal performance.

Model | Filtering Surface (m2) | Inner Diameter (mm) | Nominal Volume | Stirrer Motor Power (Kw) |

NFD-300 | 0.7 | 300 | 0.02 | Manual |

NFD-500 | 0.19 | 500 | 0.15 | 2.2 |

NFD-800 | 0.5 | 800 | 0.53 | 3 |

NFD-1000 | 0.78 | 1000 | 0.93 | 5.5 |

NFD-1400 | 1.53 | 1400 | 2 | 11 |

NFD-1600 | 2 | 1600 | 2.7 | 15 |

NFD-2000 | 3 | 2000 | 4.8 | 18.5 |

NFD-2300 | 4 | 2300 | 6.8 | 22 |

NFD-2600 | 5.3 | 2600 | 9.1 | 22 |

NFD-3000 | 7 | 3000 | 14.4 | 37 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap