- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Feature:

S-80L S-100L double-layer glass reactor is a new type of frequency conversion speed-regulated double-layer glass reactor developed and produced by our company. It has more safety and easy-to-operate design. The double-layer glass reactor produced by our company is easy to operate, The appearance is beautiful and generous, and the structure is novel and practical. It is an ideal experiment and production equipment for biopharmaceutical and new material preparation.

Advantage:

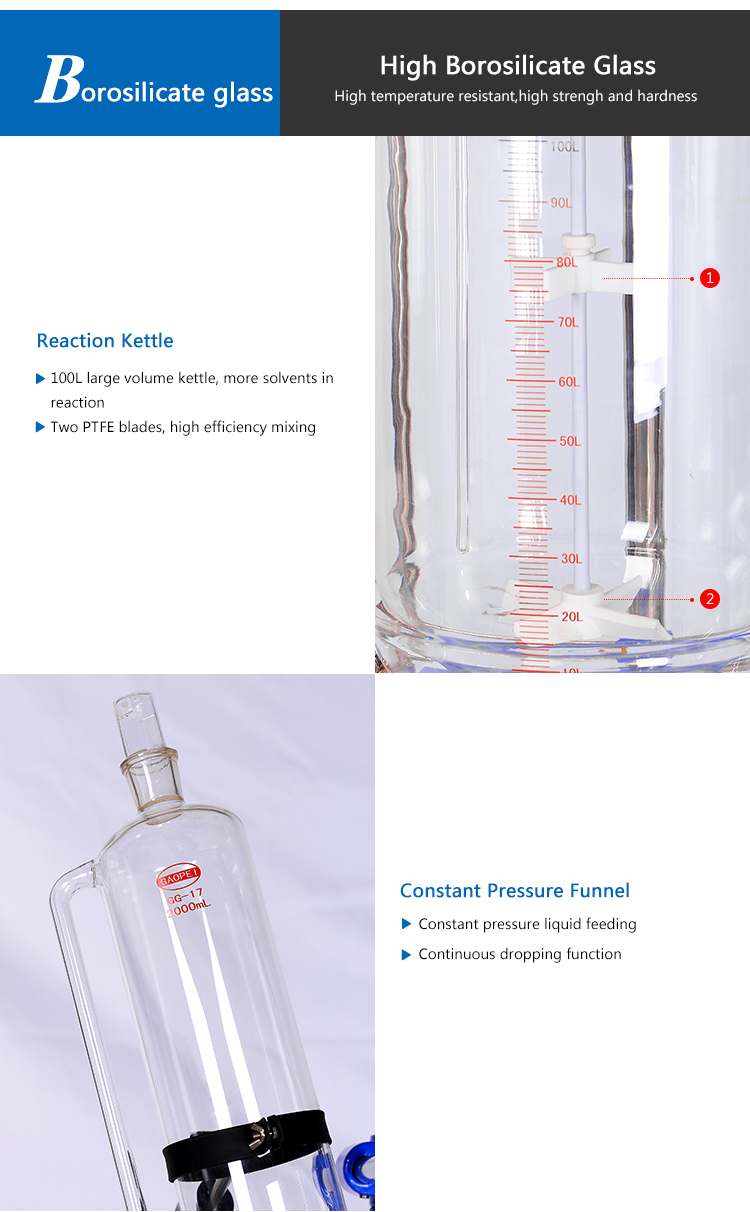

1. Using GG17 high borosilicate glass, it has good chemical and physical properties.

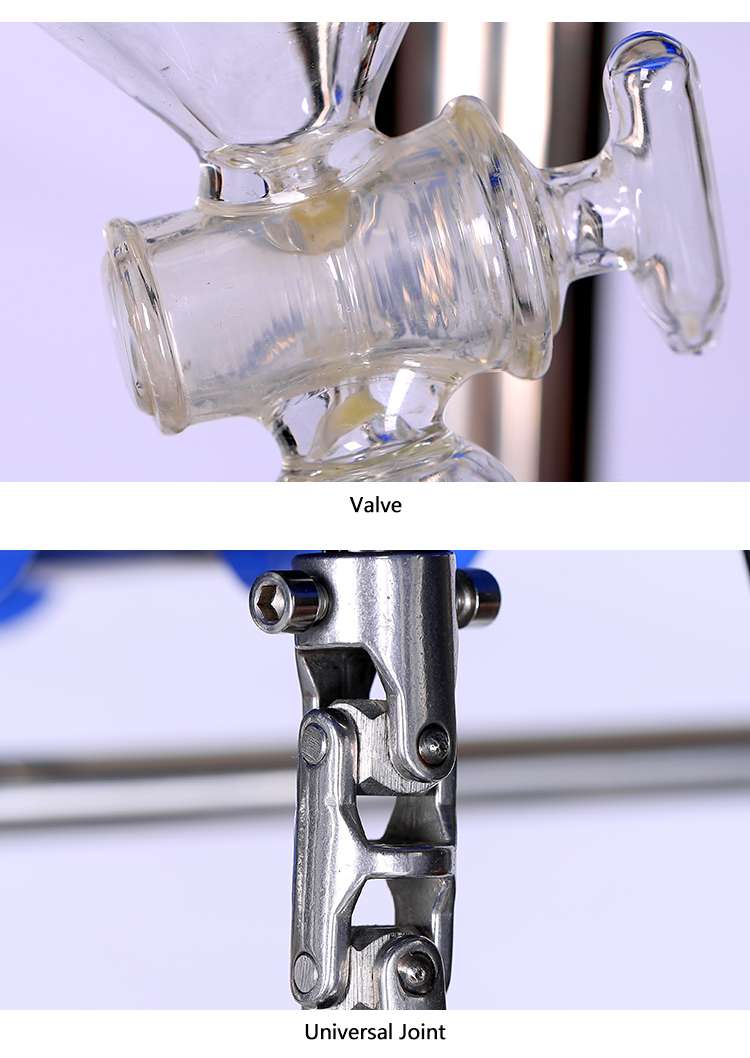

2. The lower discharge port is equipped with a flange port and a PTFE valve. There is no dead angle in the container, and it can be disassembled for easy material discharge.

Easy to clean.

3. The temperature and speed adopt digital display, which is easy to observe the material reaction.

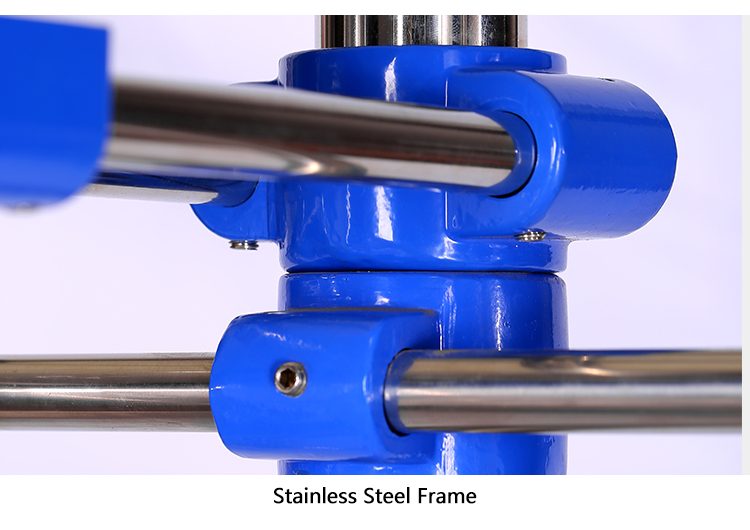

4. The support part of the kettle body is made of high-quality stainless steel pipes and cast aluminum materials, which are beautiful and generous, and the overall structure is stable.

5. Standard gears, no backlash, wear-resistant.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

1.What is the working principle of the double glass reactor?

The glass reactor is sandwiched by the double-layer reactor, and a constant temperature (high or low temperature) hot melt or cooling medium is injected to heat or cool the materials in the reactor at a constant temperature, and the double-layer glass reactor can provide stirring. The materials are reacted in the reaction kettle, and the evaporation and reflux of the reaction solution can be controlled. After the reaction is completed, the materials can be discharged from the discharge port at the bottom of the kettle, and the operation is extremely convenient.

2. What are the accessories for the glass part of the double-layer glass reactor?

Double-layer kettle body, kettle cover, constant pressure dropping funnel, distillation elbow, serpentine condenser, thermometer sleeve, inlet and outlet valve, lower discharge valve, suction elbow, hollow plug.

3. What is the supporting equipment for the low-temperature reaction of the double-layer glass reactor?

High and low temperature integrated machine: It has both heating and cooling functions, and provides heating and cooling sources for the double-layer kettle in a circular manner, and intelligent temperature control

Low-temperature coolant circulating pump: refrigeration equipment, in a circulating manner, provides low-temperature cooling circulating water for the condensation system of the double-layer kettle, and the condensation medium is ethanol

4. What materials are used for the components of the double-layer glass reactor?

The use of high borosilicate glass has good chemical properties, is resistant to strong acids and alkalis, and can withstand a wide temperature range.

Model | S-80L | S-100L |

Stirring Power(W ) | 120 | 180 |

Stirring Speed(rpm) | 0~600(Max. 1300) | |

Stirring Shaft Diameter | 15 | |

Reaction Kettle Capacity(L) | 80 | 100 |

Power Supply | 220V 50/60 Hz | |

Note | 304 all stainless frame | |

Explosion-proof | The stirring power (W): 180, 250, 370 | |

Power supply: 220V / 50Hz or 110V / 60Hz | ||

110 V/60Hz can be customized | ||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap