- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

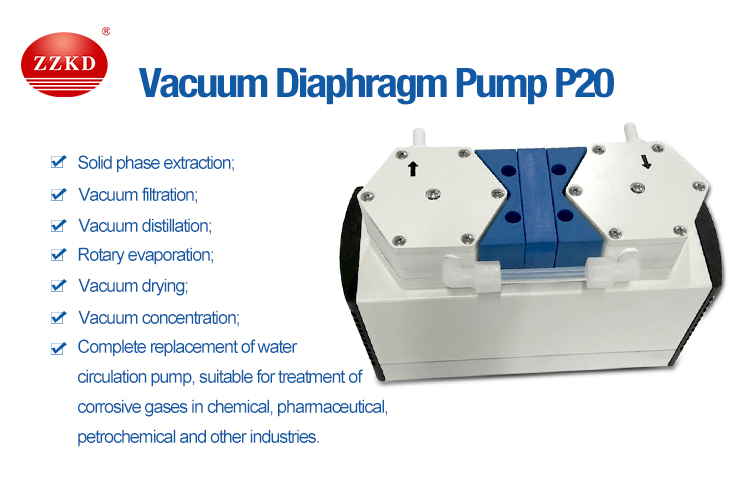

Feature:

Diaphragm vacuum pump is a new type of pump, which is often used in petrochemical, ceramics, metallurgy and other industries. It is characterized by no need to irrigate water and strong self-priming ability.

Advantage:

1. Convenient maintenance.

2. There will be no overheating.

3. Can pass through liquid containing particles.

4. It can run dry and has high safety performance.

5. No complicated control system, simple operation.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

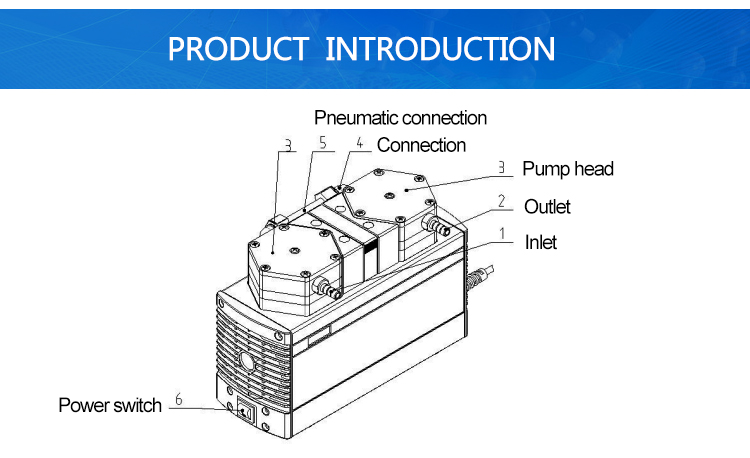

1. What is the working principle of a diaphragm vacuum pump?

The motor drives the diaphragms on the left and right plungers to reciprocate one after another through the reduction box. In the left and right pump chambers, there are four upper and lower one-way ball valve diaphragms, which change the volume in the working chamber, forcing the four one-way ball valves to open and close alternately, so as to continuously suck and discharge the liquid.

2. What should be paid attention to when using diaphragm vacuum pump?

Diaphragm vacuum pumps should be placed as close as possible to the supporting products, and at the same time, the pump should be as close as possible to the pumped liquid. When the inlet pressure exceeds 10 feet (3 meters) of liquid column, a slow pressure regulator is required to extend the service life of the diaphragm. If the equipment is a hard pipe, use a short hose to connect the pump and the pipe. The hose can slow down the vibration and distortion of the pipeline. It is recommended to use a pressure stabilization tank to further reduce pulses in the fluid.

3. How to install the diaphragm vacuum pump?

The best installation should be at the connection of the shortest and straightest inlet and outlet pipelines. Try to avoid additional pipe bends and fittings. The pump body should be able to independently support all pipelines. Moreover, the piping should be arranged in order to avoid stress on the pump body piping.

Model | P20-2 | |

Votalge & frenquecy | 110 V/50 Hz | 220 V/50 Hz |

Power | 130W | 120 W |

Pump head type | Two-stage | |

Ultimate vacuum [mbar abs.] | 8 mbar | |

Operation pressure | 1 bar (Max) | |

Flow rate [l/min] at atm. pressure | 20 L/min | |

Connectors for tube (mm) | 10mm | |

Permissible gas and | +5 ℃ ~ +40 ℃ | |

Pump head | PTFE | |

Diaphragm | PTFE coated | |

Valves | FKM or FFPM | |

Rotate speed | 1450 RPM | |

Humidity | <80% | |

Dimension (LxWxH) | 315x165x210 mm | |

Weight | 9.6Kg | |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap