- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

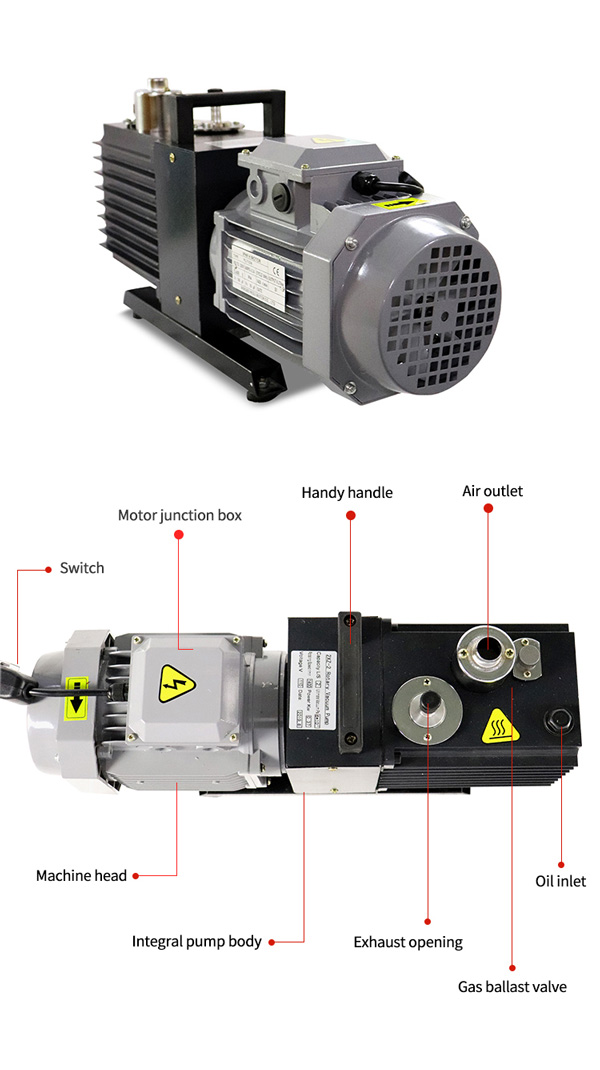

Rotary vane vacuum pump is mostly small and medium-sized vacuum pumps. There are two types of rotary vane vacuum pump: single-stage rotary vane vacuum pumps and two-stage vacuum pumps. 2XZ series rotary vane vacuum pumps can be used alone or as backing pumps for booster pumps, diffusion pumps, molecular pumps, and titanium pumps. Used in electronic device manufacturing, vacuum drying, filtration, welding, metal smelting and other fields.

1. The vacuum pump must be installed in a place with a clean environment and dry air. The room temperature should be between 5-40°C. The large pump must be fixed on a solid cement foundation with bolts.

2. Before unpacking the wooden box of the pump, check whether the wooden box is damaged. Open the wooden box to check whether the pump is damaged, whether the motor is damaged or damp, and if it is damaged or damp, it must be repaired and dried before installation.

3. The suction port on the upper part of the pump suction cylinder has been sealed with a metal gland when leaving the factory. During installation, it is necessary to check whether the seal is damaged, whether there are sundries and dirt in the pump body, and perform maintenance and cleaning work if necessary.

4. When the pump is connected to the vacuum system, the connecting pipe must be cleaned inside and outside, and the joint of the pipe must be sealed with a vacuum oil-resistant rubber gasket. It is strictly forbidden to drop foreign matter into the pump.

5. Remove the protective cover and V-belt and turn the pulley of the pump by hand for 2-3 turns to check whether the rotation is normal. Before turning on the power, it is necessary to check whether the power supply voltage, frequency, and number of phases meet the requirements on the motor nameplate. After turning on the power, the direction of rotation of the motor should be the same as that of the pump. Put the triangular tape guard on.

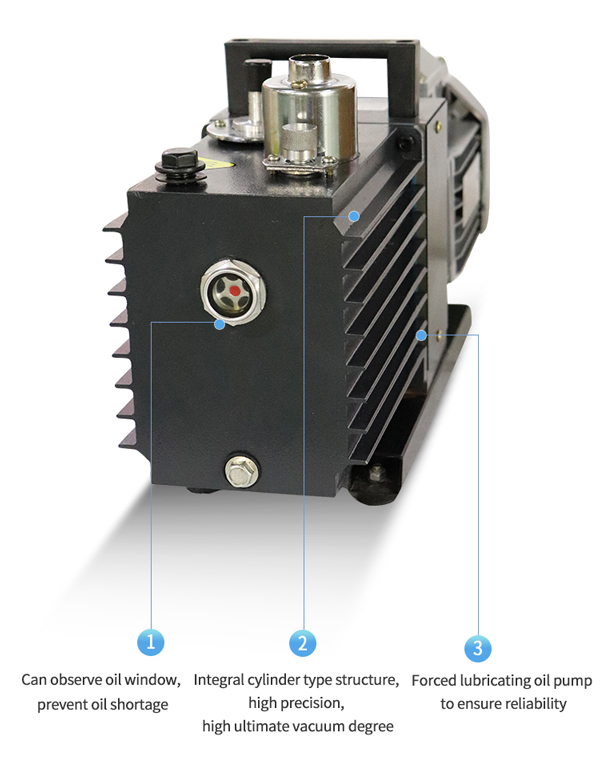

6. Unscrew the filling screw plug on the fuel tank cap, pour vacuum oil into the fuel tank until the oil level reaches the center line of the oil mark. When the room temperature is too low in winter, the oil must be heated to 15°C before injection, and the screw plug should be tightened after the oil is injected. When the pump is in normal operation, the oil level in the oil tank shall be kept on the oil level line and shall not be exceeded. It also adopts the method of injecting vacuum oil from the suction port, and the clean vacuum oil will clean and lubricate the internal parts of the pump, making it run more lightly.

7. After the installation is completed, the surroundings of the pump must be cleaned. The exterior of the pump and motor must be wiped clean.

1. Fast pumping speed, small size, light weight, low noise, easy maintenance, high ultimate vacuum, etc.

2. There is a reliable dust-proof device. For other rotary vane pumps, when the debris passes through the dust-proof device, it can be connected into the pump chamber. However, when the vacuum pump produced by our company passes through the dust-proof device, the debris can only fall around the outside of the dust-proof device. In this way, the normal operation of the pump is ensured, and the phenomenon of debris entering the pump cavity is completely solved.

3. There is a compound screw with an air release valve and an oil inlet hole. The oil inlet holes of the two-stage rotary vane pump are all designed on the low-level exhaust valve seat inside the oil tank. When the oil hole is blocked, you need to drain the oil and remove the oil tank to clear the oil hole. As long as the vacuum pump unscrews the compound screw, the oil hole can be dredged, and sundries and water vapor can also be discharged. It is fast and labor-saving, which greatly improves the working efficiency of the pump.

The noise is very small, below 60 decibels.

Check that the motor direction is correct. Before starting the pump, turn the belt 2 to 3 times by hand to drain the oil in the cylinder. Always pay attention to the oil quality of the pump. If the oil quality is not good, the viscosity is too high, the moisture is too much, the oil quality is rusted, etc., the new oil should be replaced immediately.

The best working temperature is in the range of 20~25℃.

Widely used in electronics industry, instrumentation, vacuum coating, vacuum packaging, vacuum smelting, vacuum drying, vacuum filtration, vacuum testing, medical equipment, refrigeration equipment, food hygiene, petrochemical, scientific experiments and other fields.

2XZ-0.5, 2XZ-1, 2XZ-2, 2XZ-4, 2XZ-8, 2XZ-15.

MODEL | 2XZ-0.5 | 2XZ-1 | 2XZ-2 | 2XZ-4 | 2XZ-8 | 2XZ-15 | |

Exhausting Speed(L/S) | 0.5 | 1 | 2 | 4 | 8 | 15 | |

Ult.Vacuum(Pa) | Without Gas Ballast | ≤6×10-2 | |||||

With Gas Ballast | ≤6.5 | ≤1.33 | |||||

Rotary Speed (r/min) | 1400 | 1410 | |||||

Working Voltage(V) | 220 | 220/380 | |||||

Motor Power(kW) | 0.18 | 0.25 | 0.37 | 0.55 | 1.1 | 1.5 | |

Inlet Diameter(mm) | Φ16 | Φ25 | Φ40 | ||||

Temp. Rise of Pump Oil(℃) | ≤40 | ≤45 | ≤65 | ≤70 | |||

Oil Capacity(L) | 0.5 | 0.55 | 0.8 | 0.1 | 2.5 | 4 | |

Size(W*D*H, mm) | 445*130*254 | 467*130*254 | 488*145*280 | 528*145*280 | 575*172*350 | 703*338*453 | |

Weight(kg)(With3-phase Motor) | 13.5 | 15 | 20 | 23 | 48.5 | 77.5 | |

Noise(Db) | ≤60 | ||||||

Vibration Reference Number(U) | ≤80 | ||||||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap