- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Advantage:

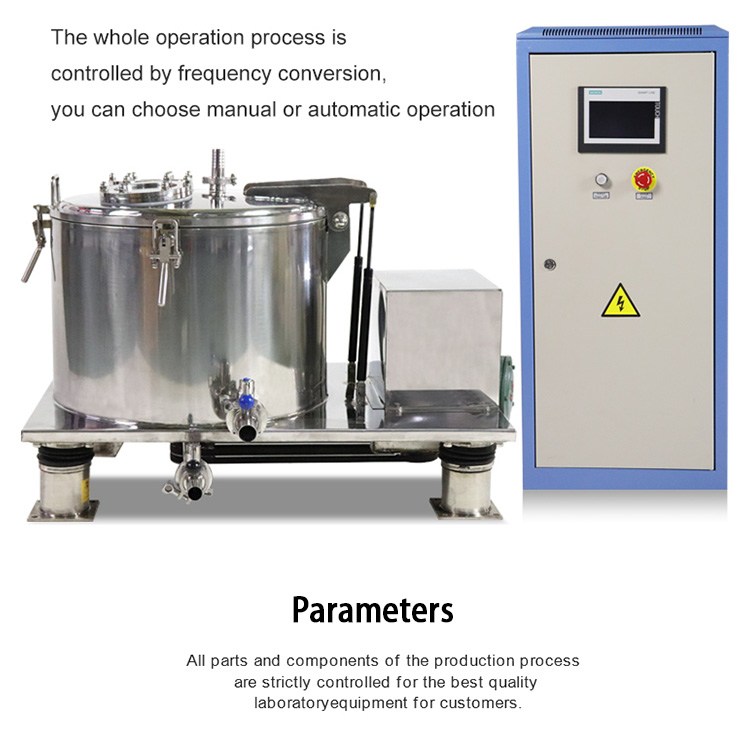

The stainless steel centrifuge has aseptic, hygienic, airtight explosion-proof, multiple safety protection and multiple configuration options, controlled by a fully automatic program, and is widely used in the pharmaceutical, fine chemical and food industries.

Features:

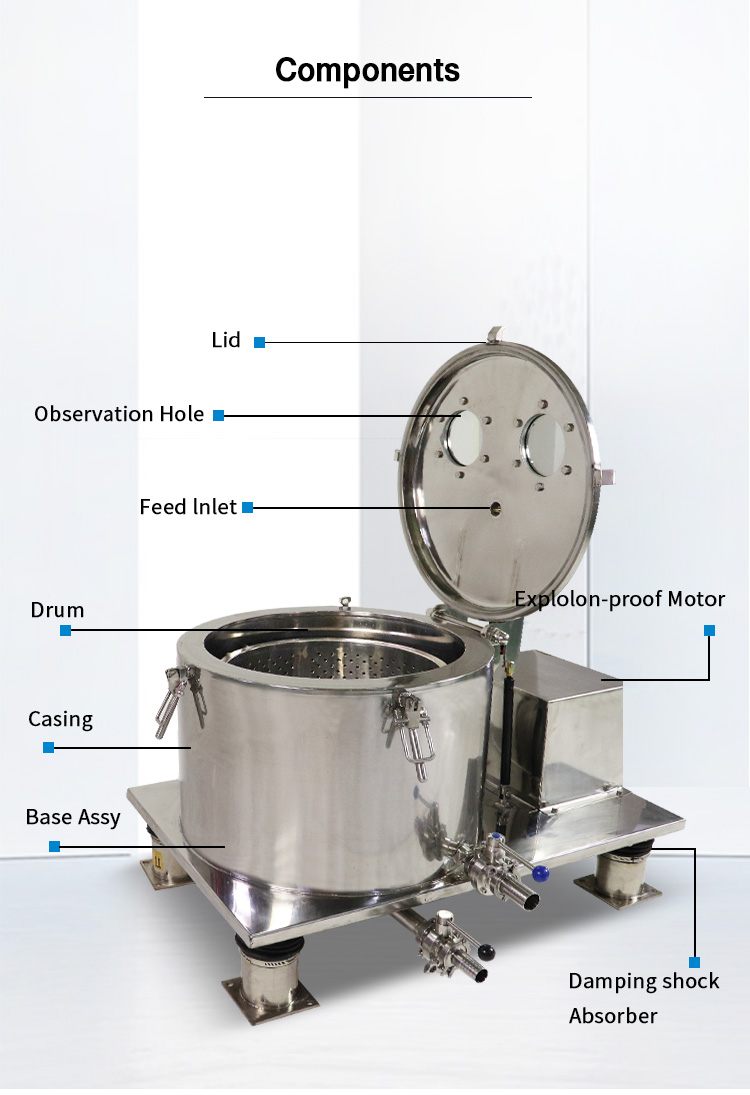

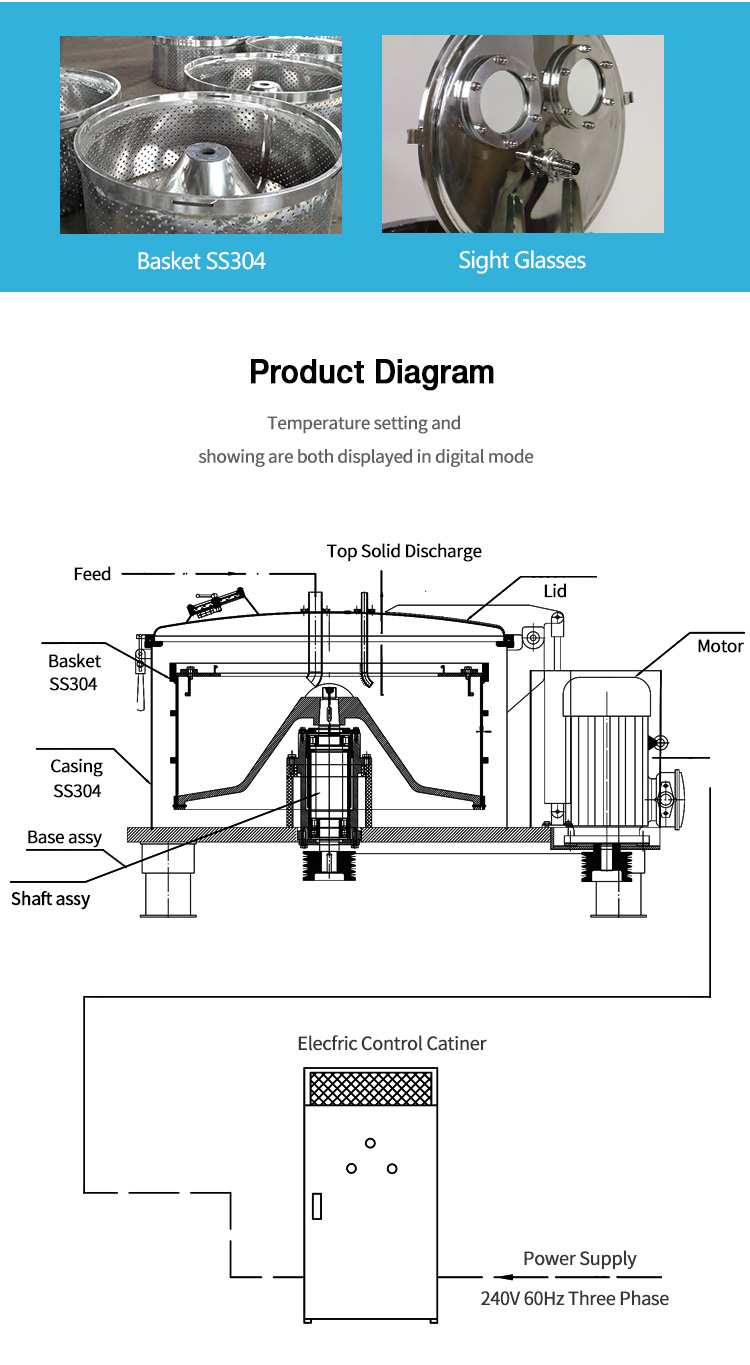

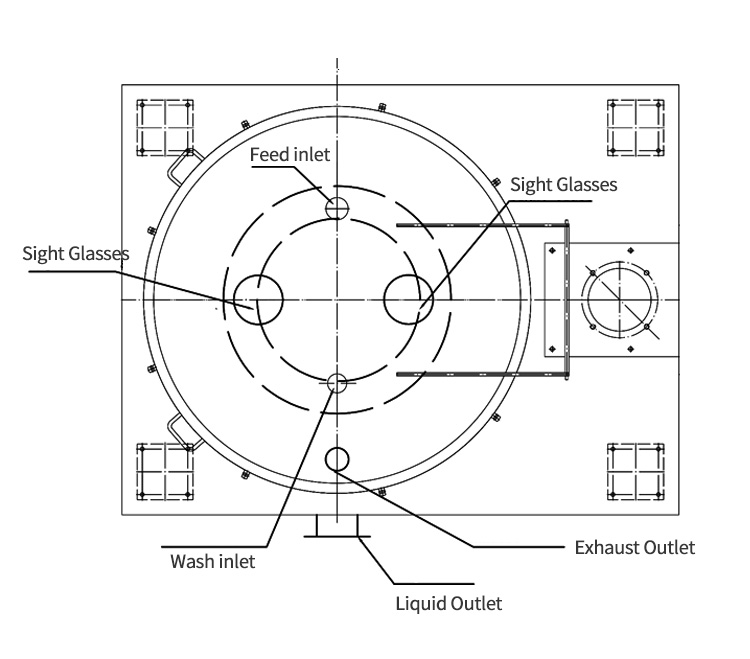

1. The structure design is reasonable, and the shell is tightly designed with a large flip cover. The space between the centrifuge shell and the drum can be thoroughly cleaned. The parts in contact with the materials inside the centrifuge, the external structural parts and fasteners of the centrifuge are all made of stainless steel.

2. Airtight structure, the seals are made of silicone rubber or fluorine rubber, which can achieve airtight explosion-proof requirements, and is suitable for applications in toxic, flammable and explosive fields.

3. The inner and outer shell design of the bearing seat can be lifted vertically from the upper part, which is convenient for disassembly and maintenance and reliable sealing.

4. The machine cover is a spring-type large flip cover, and the seal is made of silicon rubber.

5. Equipped with a high-viscosity liquid damping shock absorber, which can eliminate vibration more effectively and simplify daily maintenance.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

1. What should be paid attention to in the use of stainless steel centrifuge?

The stainless steel centrifuge should be placed on a very solid ground and equipped with dust-proof and moisture-proof equipment to ensure that the centrifuge chamber reaches a certain degree of vacuum and operates normally. Do not store any dangerous items near the stainless steel centrifuge. Choose a suitable rotor and control the speed of the rotor. The speed setting should not exceed the maximum speed.

2. Under what circumstances should the stainless steel centrifuge reduce the maximum speed of the rotor?

When the rotor's operating time and number of operations reach the specified life; when the rotor is locally damaged or slightly corroded in the pipe hole; when the average density of the sample exceeds 1.2g/cm3; when the rotor is exposed to high temperatures.

3.Is the stainless steel centrifuge resistant to acid and alkali?

Of course, the main characteristic of stainless steel is acid and alkali resistance.

Mode | KDCM-10 | KDCM-30 | KDCM-50 | KDCM-100 |

Diameter ( mm) | 300 | 450 | 600 | 800 |

Capacity (L) | 5 | 20 | 40 | 100 |

Max Load (kg) | 7.5 | 30 | 60 | 135 |

Motor (kw) | 0.75 | 1.5 | 3 | 5.5 |

weight (kg) | 200 | 300 | 650 | 1600 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap