- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Advantage:

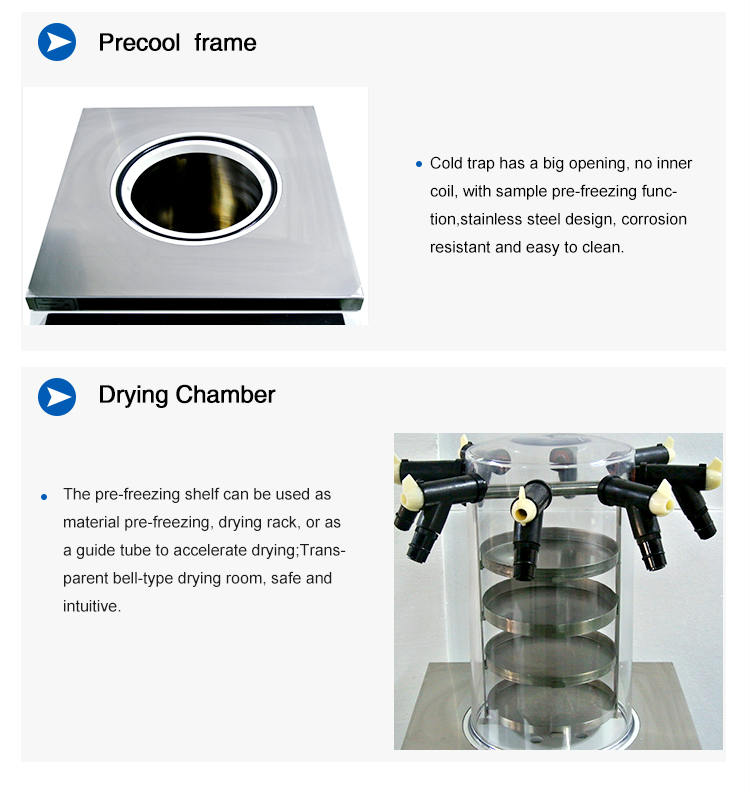

It is suitable for freeze-drying of conventional materials in bulk (liquid, pasty, solid). Flasks can be connected outside the drying chamber to dry the materials frozen on the inner wall of the bottle. At this time, the flask is used as a container to connect to the manifold outside the drying box. On top, the materials in the flask are heated at room temperature. Through the multi-manifold switch device, the flask can be removed or installed at any time as needed without stopping the machine.

Features:

1. The drying chamber is integrally formed. No bonding, high strength, no leakage.

2. Mixed environment-friendly refrigerant, green environment-friendly cooling capacity is large.

3. Liquid crystal display drying curve.

4. The internal heat exchanger effectively reduces the temperature of the cold trap and has a strong water catching capacity.

5. The cold trap has a pre-freezing function, saving the cost of a low-temperature refrigerator.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

Grouped equipment:

FAQ:

1. What is the freeze drying efficiency of your freeze dryer?

Different types of freeze dryers have different working efficiency. If you want to speed up the freeze dryer's working speed, you can choose: eutectic point detection function, vacuum degree control function and optional power distribution defrost function. Help you speed up the working speed of the freeze dryer.

2. What are the reasons that affect the energy consumption of the freeze dryer?

Influence from the material: For example, the eutectic point of the material, the degree of heat sensitivity, the size or thickness, etc., will have a greater impact on the required drying time and operating cost.

The influence of the adopted process route: such as the determination and grasp of the timing of material freezing rate, heating temperature, and heating rate, etc., will have an impact on the drying speed and operating cost.

3. For food, what is the difference between freeze-drying and drying?

Compared with drying technology, freeze-drying technology can retain as many nutrients as possible in food, such as color, aroma and taste, and effectively extend the shelf life of food. The drying method will cause the material to shrink and deform and the nutrients will be greatly lost due to high temperature drying.

Model | KD-12N | |

Specification | Gland multi-manifold | |

Freeze-dried area(m2) | 0.08 | |

Water catching capacity(kg/ time) | 3 | |

Vial bottle bottling | Φ12mm | 560 |

Φ16mm | 285 | |

Φ22mm | 165 | |

Number of eggplant bottles | 8 | |

Ampoule interface | / | |

Disk loading solution(L) | 1 | |

Material tray size(mm) | Φ180 | |

Material spacing(mm) | 70 | |

Material tray size | 3 | |

Cold trap size(mm) | Φ250×250 | |

Cold trap minimum temperature(°C) | ≤-56 ( No load) | |

-80°C cold trap minimum temperature(°C) | ≤-80 ( No load) | |

Ultimate vacuum(Pa) | ≤5 ( No load) | |

PowerKw(220V50Hz) | 0.95 | |

Ambient temperature(°C) | ≤25 | |

Overall dimensions(mm) | 600*450*720+440 | |

-80°C overall size(mm) | 700*450*720+440 | |

Total Weight(kg) | 72 | |

Special Note | The size and weight of the whole machine do not include the external vacuum pump. The height of the B/D lyophilizer does not include the manual gland handle (the height is about 70mm) | |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap