- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

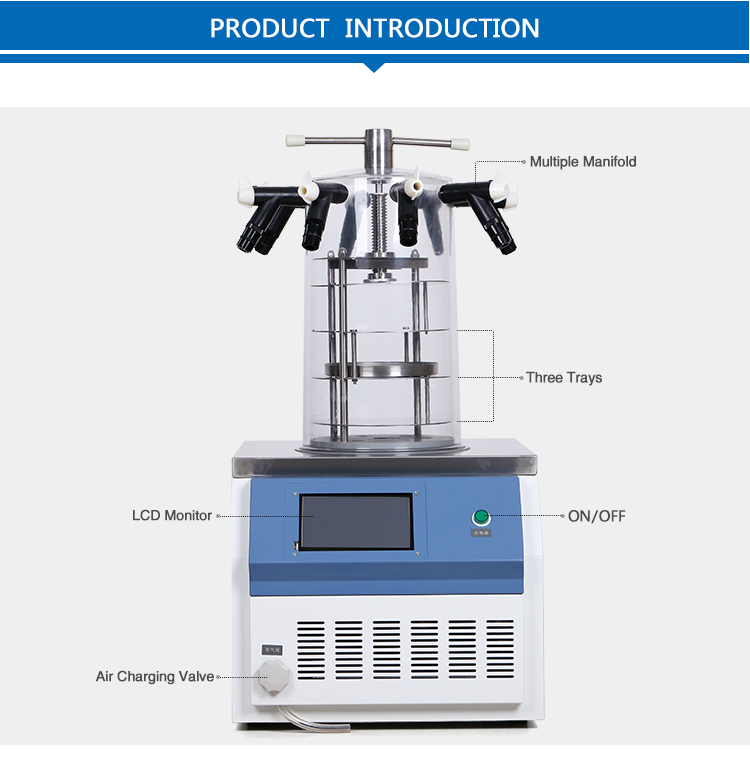

KD-10ND has a heating function to speed up the drying process.

Advantage:

Vacuum freeze-drying technology, also called freeze-drying for short, is also called sublimation drying. It is a method of pre-freezing water-containing materials and then sublimating under vacuum. Freeze-dried items have basically the same original biological and chemical characteristics, and are easy to store for a long time. After adding water, they can return to the shape before freeze-drying and can maintain their original characteristics. Therefore, freeze drying technology is widely used in the chemical industry, biological products, food freeze dryers and other fields.

Features:

1. Integrated structure design, small size, no external flange, easy to use, no leakage.

2. Specialized gas diversion technology, uniform ice trapping by cold trap, strong ice trapping ability.

3. The cold trap has a large opening, no inner coil, with sample pre-freezing function, and no low-temperature refrigerator.

4. All materials in contact with the product use inert materials to meet GLP requirements.

5. All stainless steel gas (drain) valves, designed and produced by our company, are safe, anti-corrosion and no leakage.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

Grouped equipment:

FAQ:

1. How to choose a desktop freeze dryer and a vertical freeze dryer?

If you need freeze-dried materials with a temperature higher than -56°C and require less freeze-dried materials, you can choose a desktop freeze dryer.

If you need a lot of freeze-dried materials and have higher requirements for cooling temperature, you can choose a vertical freeze dryer.

2. What are the uses of the freeze dryer?

Biological specimens and biological tissues, food drying, preparation of Chinese herbal medicine, preparation of ultra-fine powder, etc.

3. What models of your freeze dryer have?

KD-10N, KD-10ND, KD-12N, KD-12ND, KD-18N, KD-18ND.

4. What are the steps of the laboratory freeze-drying machine?

Turn off the vacuum system and refrigeration system, if not used for a long time, directly unplug the equipment power cord. Lift the plexiglass cover, take out the freeze-dried sample and save it. After the ice in the cold trap turns into water, the water needs to be drained from the quick inflation valve port.

Model | KD-10ND | |

Specification | Normal type | |

Freeze-dried area(㎡) | 0.125 | |

Water catching capacity(kg/ time) | 3 | |

Vial bottle bottling | Φ12mm | 920 |

Φ16mm | 480 | |

Φ22mm | 260 | |

Number of eggplant bottles | / | |

Ampoule interface | / | |

Disk loading solution(L) | 1.5 | |

Material tray size(mm) | Φ200 | |

Material spacing(mm) | 70 | |

Material tray size | 4 | |

Cold trap size(mm) | Φ250×150 | |

Cold trap minimum temperature(°C) | ≤-56 ( No load) | |

-80°C cold trap minimum temperature(°C) | ≤-80 ( No load) | |

Ultimate vacuum(Pa) | ≤5 ( No load) | |

PowerKw(220V50Hz) | 1.11 | |

Ambient temperature(°C) | ≤25 | |

Overall dimensions(mm) | 590*460*400+440 | |

-80°C overall size(mm) | 700*450*720+440 | |

Total Weight(kg) | 59 | |

Special Note | The size and weight of the whole machine do not include the external vacuum pump. The height of the B/D lyophilizer does not include the manual gland handle (the height is about 70mm) | |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap