- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

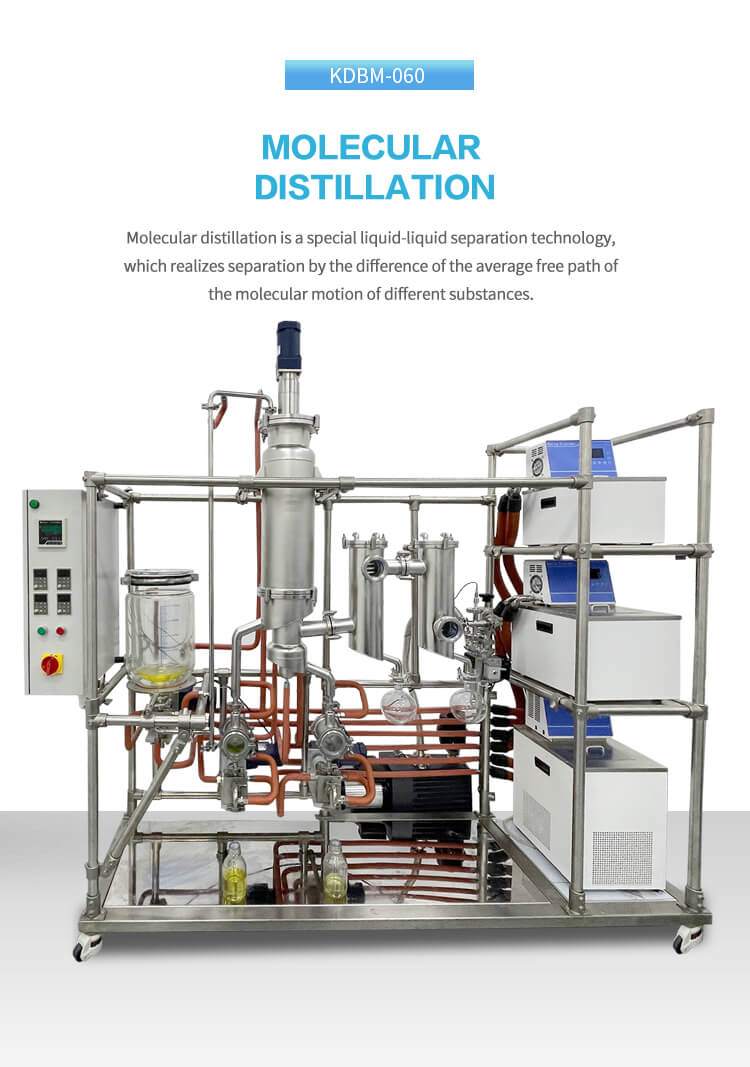

In the ever-evolving world of chemical and biological pharmaceuticals, the demand for efficient extraction and distillation processes has never been greater. One technology that has been at the forefront of this revolution is the Short Path Distillation System Machine. In this article, we will delve into the intricacies of this cutting-edge equipment, exploring its features, applications, and the impact it has had on various industries.

Short Path Distillation, often referred to as SPD, is a specialized distillation technique used to separate and purify compounds based on their boiling points. Unlike traditional distillation methods, SPD operates under reduced pressure, which allows for lower operating temperatures and minimizes the risk of compound degradation. This innovative process is the cornerstone of the Short Path Distillation System Machine.

The Short Path Distillation System Machine consists of several essential components:

1. Evaporator: This is where the raw mixture is heated, causing the volatile compounds to vaporize.

2. Internal Condenser: Vaporized compounds are condensed back into a liquid phase within this component.

3. External Condenser: Further condensation occurs in this unit, ensuring efficient separation.

4. Collection Flask: The purified compounds are collected in this flask, ready for use or further processing.

The versatility of the Short Path Distillation System Machine extends its application to various industries. Here are some notable examples:

In the pharmaceutical sector, precision and purity are paramount. Short Path Distillation is instrumental in the extraction of active pharmaceutical ingredients (APIs) from plant materials. This process guarantees high-quality, contaminant-free products, meeting stringent regulatory requirements.

As the cannabis industry continues to grow, so does the need for efficient extraction methods. Short Path Distillation has become the gold standard for producing pure and potent cannabis concentrates, such as distillates and isolates.

The production of essential oils demands delicate handling of plant materials to preserve their aromatic compounds. Short Path Distillation allows for the extraction of these valuable oils with minimal heat exposure, resulting in superior fragrance and therapeutic properties.

In the food and beverage industry, Short Path Distillation is utilized to extract flavors, aromas, and essential oils from various natural sources. This enhances the quality and consistency of products like essential oils, flavorings, and herbal extracts.

The Short Path Distillation System Machine also finds extensive use in laboratories and research facilities. Scientists and researchers rely on SPD for the precise separation and purification of compounds, enabling groundbreaking discoveries and innovations.

Short Path Distillation offers several distinct advantages over traditional distillation methods:

1. High Purity: The reduced operating temperatures and minimal exposure to oxygen result in purer end products.

2. Efficiency: SPD processes are incredibly efficient, minimizing waste and maximizing yield.

3. Versatility: The technique can be adapted for a wide range of applications and compounds.

4. Scalability: Whether you need a small-scale lab setup or a large industrial system, Short Path Distillation can accommodate your needs.

5. Cost-Effective: While initial investment may be higher, the long-term cost savings in terms of energy and product quality are significant.

The Short Path Distillation System Machine is a game-changer in the world of extraction and distillation. Its precision, efficiency, and adaptability have made it an invaluable asset across various industries. Whether you're in pharmaceuticals, cannabis extraction, essential oils, or research, embracing this technology can lead to higher-quality products and increased productivity. As innovations continue to emerge, Short Path Distillation remains a driving force in shaping the future of chemical and biological pharmaceutical equipment.

Model | KDBM-60 | KDBM-80 | KDBM-100 | KDBM-150 | KDBM-200 | KDBM-230 |

Main evaporator diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

Effective evaporation area (m2) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

Feeding speed (kg / h) | 0.5-3 | 1-5 | 2-8 | 3-15 | 5-20 | 8-30 |

Feed tank volume (L) | 1 | 1 | 2 | 2 | 5 | 5 |

Maximum speed (R / min) | 450 | 450 | 450 | 450 | 300 | 300 |

Volume of collecting bottle (L) | 1 | 1 | 2 | 3 | 5 | 5 |

Motor power (W) | 90 | 120 | 120 | 120 | 200 | 200 |

Operating temperature (℃) | -90~220 | |||||

Voltage (V/Hz) | 220/50 (The voltage can be customized) | |||||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap