- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

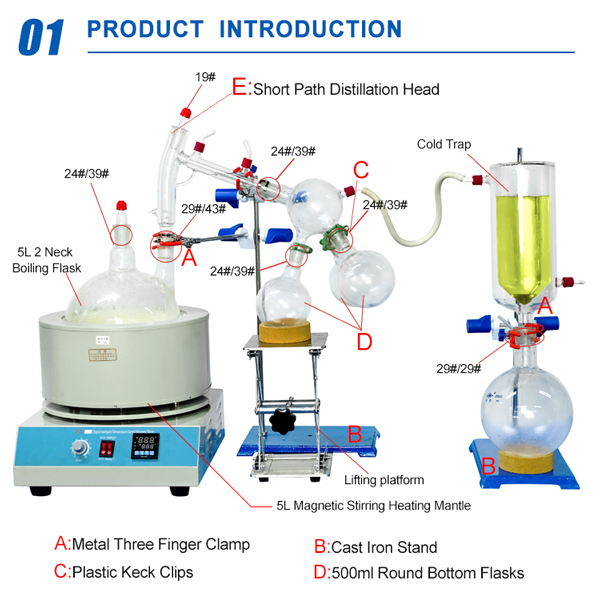

The SPD-5L short-path distillation equipment manufactured by ZZKD is of the best quality, made of high borosilicate glass and 304 stainless steel, which is corrosion-resistant and durable.

The SPD-5L short-path distillation kit consists of three parts: machinery, glass and constant temperature water bath. The installation is simple and convenient, the specific steps are as follows:

1. Put the shelf on the table smoothly, if it is not flat, you can adjust the screws of the four hard rubber feet under the bottom plate

2. Face the vacuum gauge rod installed on the stainless steel rod to the installer, and tighten the nuts at both ends.

3. The motor is 48cm away from the chassis, tilt to the right about 25 degrees, and tighten the screws of each part.

4. Fix the inverter on the stainless steel frame, and then plug in the five-pin plug.

5. Use the fixing clips to fix the condenser flange. The condenser is vertical, with each pipe fitting pointing backwards.

6. Insert the feed tube into the bottle connected to the condenser.

7. Install the evaporating flask and the receiving flask, and connect them with bottle clamps.

8. Place the water bath under the receiving bottle, add water to 2/3 (tap water for 1-2 days)

9. The exhaust pipe of the condenser is connected to the vacuum pump with a vacuum pipe, and the other end is connected to the chiller.

1. High-quality borosilicate glass, strong and durable.

2. The maximum vacuum degree is 0.098Mpa.

3. There is a special feeding port, which is convenient for feeding.

4. Detachable, easy to replace parts.

5. Frosted port connection, good sealing.

The degree of vacuum is the most important process parameter of the rotary evaporator, and users often encounter that the degree of vacuum cannot be achieved. It is often related to the nature of the solvent used, such as water, ethanol, acetic acid, ether, petroleum ether, chloroform, and toluene are often used as solvents in the biochemical and pharmaceutical industries. However, ordinary vacuum pumps are not resistant to organic solvents, and special vacuum pumps with strong corrosion resistance are selected. (It is recommended to use a water circulation vacuum pump, which is sold by our company). Simple leak detection instrument method - pinch off the external vacuum tube, and observe whether the vacuum gauge can keep up for five minutes without dropping. If there is leakage, check whether the sealing joint and the rotary shaft seal are effective (see maintenance). If the instrument is working properly, check the vacuum pump and vacuum lines.

The motor of this instrument adopts Class E insulation, and the winding adopts high-strength polyester enameled wire. The altitude does not exceed 1000 meters, and the ambient temperature does not exceed 40°C. Continuous use will increase the surface temperature of the motor (the difference between the surface temperature and the ambient temperature does not exceed 45°C, which is normal and can be used safely). If the temperature exceeds 45°C, check the lubrication system of the relevant drive system (see Maintenance). If the ambient temperature is high and the temperature of the water bath is high, the user can use a fan to cool down.

Circulating water multifunctional vacuum pump

Diaphragm vacuum pump

Rotary Vane Vacuum Pump

Low temperature coolant circulation pump

Low temperature and constant temperature reaction tank

The pressure difference between the boiling film and the condensing surface is the driving force for the direction of steam flow, and a small pressure drop will cause the steam to flow. It operates at 1mbar and requires a short distance between boiling and condensing surfaces. Distillers made according to this principle are called short-path stills.

Molecules diffuse from the main body of the liquid phase to the evaporation surface, the molecules evaporate freely on the surface of the liquid layer, the molecules fly from the evaporation surface to the condensation surface, and the molecules condense on the condensation surface.

The maximum vacuum degree is 0.098Mpa.

First turn on the vacuum coolant circulation pump, adjust the temperature and pre-condense, turn on the scraping film rotor, test run to see if its rotation is uniform and continuous, and then listen to the sound of scraping film for noise.

Model | Parts name | Parts number |

5L short path distillation | 5000 ml Digital Heating Mantle | 1 |

5000 ml 2 Neck Boiling Flask | 1 | |

Short Path Distillation Head | 1 | |

Cow Receiver | 1 | |

1000 ml Round Bottom Flasks | 3 | |

Plastic Keck Clips | 7 | |

Cast Iron Stand | 2 | |

Metal Three Finger Clamp | 1 | |

Cold trap | 1 | |

PTFE magnetic stirring bar | 1 | |

Lifting platform | 1 | |

backing ring | 1 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap