- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

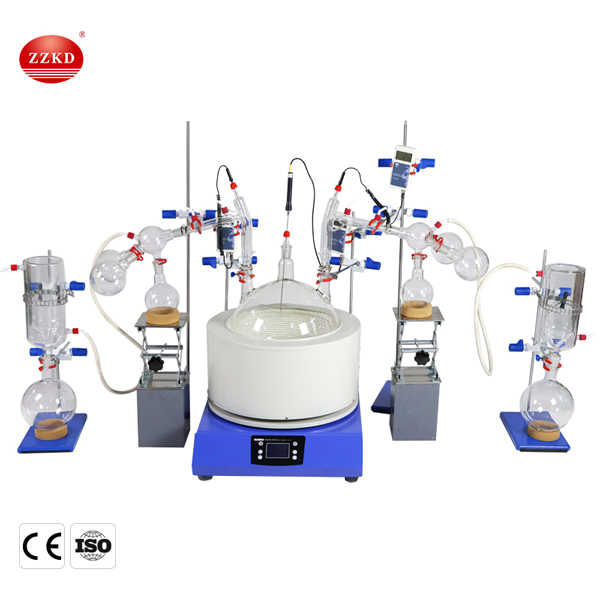

This short path distillation equipment has simple structure, small footprint, high evaporation efficiency and high recovery efficiency, and is mainly used in fractionation process.

After the mixture boils, the steam enters the fractionation column and is partially condensed. The condensate contacts the steam that continues to rise on the way down. The two conduct heat exchange. The low boiling point components in the liquid are heated and vaporized, and the high boiling point components are still in liquid state and descend. The result is an increase in low-boiling components in the ascending vapor and an increase in high-boiling components in the descending condensate. After multiple heat exchanges in this way, it is equivalent to continuous multiple ordinary distillations. As a result, the vapor of the low-boiling point components continues to rise and is distilled out; the high-boiling point components continue to flow back into the distillation bottle, thereby separating them.

• PTFE screw thermometer joint (with fluororubber gasket)

• Down discharge port

• Vacuum jacket vapor channel

• Multiple sets of split flask distillation heads

• Made of high quality and durable high borosilicate glass

• Heating mantle plus magnetic stirring function

• The cold trap protects the vacuum pump from contamination and damage by steam

• Equipped with vacuum pump and heating & cooling equipment

• It is not suitable for high-speed operation without load;

• Keep the speed control and motor dry, because the life of the electrical box and the surrounding humidity and temperature are greatly affected;

• The bottom line must be well grounded, and the high temperature bath must be connected to the air switch;

• Throwing it within 5 minutes after cutting off the power may cause electric shock due to the discharge of the inverter or capacitor;

• Please avoid impact damage to the glass by hard objects such as watches and rings when operating the instrument;

1. Install the injector (screw the injector clockwise), the first, second and third receiving bottles, and turn on the cooling water circulation button;

2. Open the wiper rotor and adjust to the specified speed (not to exceed 400 r/min);

3. Turn on the vacuum pump after the liquid nitrogen reaches the required liquid level (not less than 1/2 of the volume of the condensation column);

4. When the pressure no longer drops, adjust the vacuum pump fine-tuning valve (not lower than 0.5 mbar);

5. After the pressure is adjusted in place, turn the injector valve counterclockwise to adjust the injection speed;

6. During the operation of the equipment, the feed liquid can be added at any time through the sample injector;

7. When the liquid volume in the injector remains about 50 m| and no more samples are injected, turn off the vacuum pump and turn back the fine-tuning valve. When the pressure shows 1000 mbar, wait for 10 minutes. After the pressure is exhausted, turn off the heater and remove the Injector, pour out the remaining sample liquid, and replace with absolute ethanol;

8. Replace the first and second receiving bottles, install empty bottles, unscrew the injector, slowly inject absolute ethanol, and use the residual heat to clean the equipment;

9. After cleaning, turn off the cooling water and the rotor, remove the sampler and receiving bottle for another wash;

10. Turn off the power and clean the countertop.

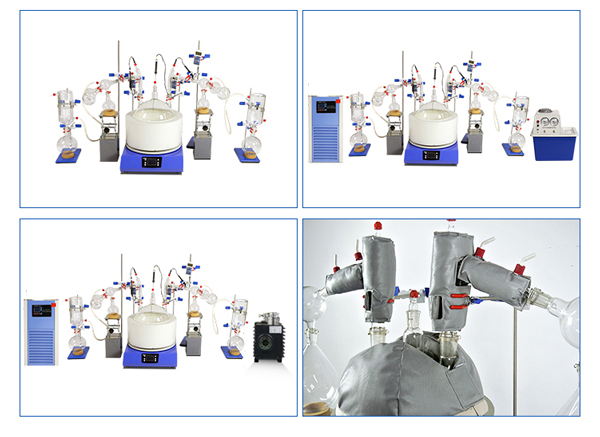

• Circulating water multifunctional vacuum pump

• Diaphragm vacuum pump

• Rotary Vane Vacuum Pump

• Low temperature coolant circulation pump

• Low temperature and constant temperature reaction tank

Heating part (electric heating jacket), evaporating flask, distillation elbow, four-neck flask, receiving flask, cold well.

Provide a large heating area, uniform heating, and rapid heating. Brushless DC motor, stable performance, low noise, long life, no spark.

In short path distillation equipment, a liquid solution or emulsion is suspended in an evaporating flask, which is connected by a short feed to a condenser or cooling unit. The evaporating flask is placed in an electric heating jacket to gradually increase the temperature of the solution to the predetermined boiling point, thereby promoting the evaporation of different compartments of the solution.

It can replace the conventional falling film evaporator and is used for distillation, purification, concentration and decolorization of petrochemical products; it is especially suitable for distillation and refining of heat-sensitive and easily oxidized chemical products; it can also be used for distillation and separation of high-boiling point products.

Model | Parts name | Parts number |

20L short path distillation | 20000 ml | 1 |

20000 ml | 1 | |

Short Path Distillation Head | 1 | |

Cow Receiver | 1 | |

3000 ml | 3 | |

Plastic Keck Clips | 7 | |

Cast Iron Stand | 1 | |

Metal Three Finger Clamp | 1 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap