- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

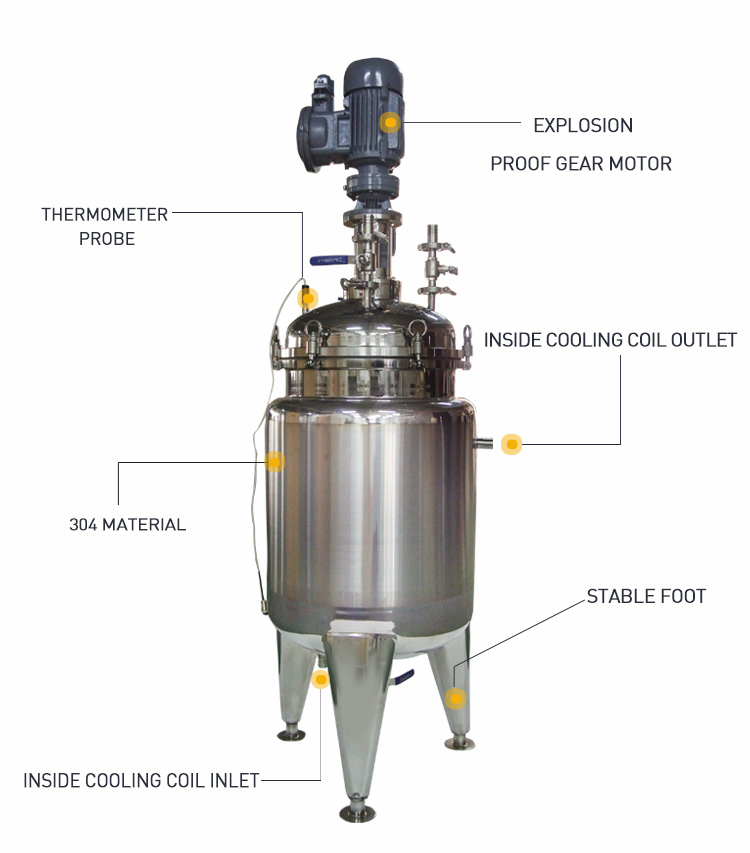

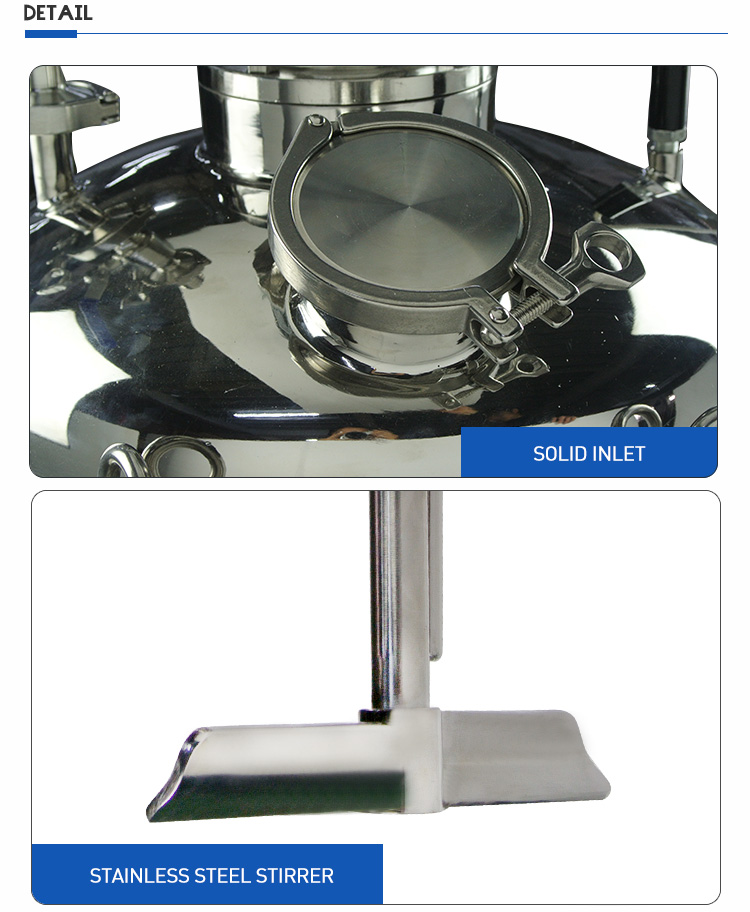

Stainless steel jacketed reactor is used in the production process of hydrolysis, neutralization, crystallization, distillation, evaporation, and other processes in the pharmaceutical, chemical, and food industries. Acid resistance, high-temperature resistance, wear resistance, and corrosion resistance.

1. You can choose steam heating, electric heating, or thermal oil heating.

2. Strong mixing force and stable motor operation.

3. Made of 304 and 316 high-quality stainless steel.

4. Fast heating, high-temperature resistance, and no environmental pollution.

5. Simple operation and low price.

After-sale:

Free maintenance for the life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

Grouped equipment:

SHZ-C circulating water vacuum pump

DLSB low-temperature coolant circulation pump

GYY circulating water (oil) bath

GDX high and low temperature integrated machine

FAQ:

1. How to maintain the stainless steel jacketed reactor?

Safety valves, thermometers, distillation holes, pressure gauges, electrical instruments, etc. must be checked regularly. When the equipment is not in use, it should be scrubbed frequently to keep the exterior and inner tank clean to achieve the purpose of durability.

2. What are the heating methods of the stainless steel jacketed reactor?

The heating method can be steam heating, electric heating, heat transfer oil heating, etc.

3. What is the capacity of your stainless steel jacketed reactor?

We have 50L, 60L, 80L, 100L stainless steel jacketed reactors, if you need another capacity, we provide customized services.

Model: | T-100L |

Capacity(L) | 100 |

Material | SS304 stainless steel |

Power Supply | 220V 50/60 Hz; 110v 60hz/ 240V60hz |

Stirring Power(W ) | 370 |

Stirring speed(rpm) | 0-180 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap