Short Path Molecular distillation applications advantages and disadvantages

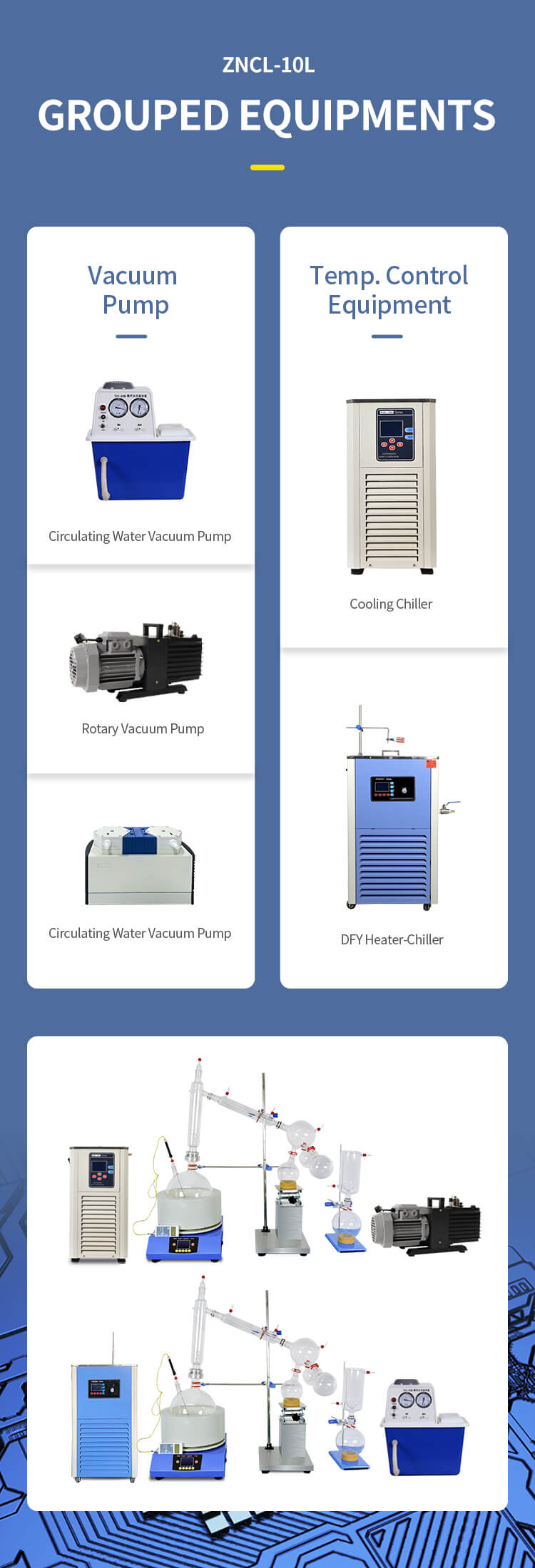

ZZKD sells short path molecular distillation equipment. We have SPD-2L short path molecular distillation, SPD-5L short path molecular distillation, SPD-10L short path molecular distillation, SPD-20L short path molecular distillation and other types of short path molecular distillation equipment, which are non-toxic, harmless, non-polluting, and non-residue, and can obtain pure and safe products.

|

SPD-2L Short Path Distillation |

2000 ml Digital Heating Mantle: 1 |

|

SPD-5L Short Path Distillation |

5000 ml Digital Heating Mantle: 1 |

|

SPD-10L Short Path Distillation |

10000 ml Digital Heating Mantle: 1 |

|

SPD-20L Short Path Distillation |

20000 ml Digital Heating Mantle: 1 |

Application of short path molecular distillation:

According to the theory of molecular motion, the molecules of a liquid mixture will intensify their motion when heated, and when they receive enough energy, they will escape from the liquid surface and become gaseous molecules. As the molecules of the gas phase above the liquid surface increase, some of the gas will return to the liquid. When the external conditions remain constant, the dynamic balance of molecular motion will eventually be reached. From a macro point of view, the balance is reached.

According to the molecular mean free path formula, different types of molecules have different effective diameters of molecules, so their mean free paths are also different, that is, different types of molecules, from a statistical point of view, they will not collide with other molecules after they escape the liquid surface. The flight distance is not the same. The separation function of short path molecular distillation is realized by using the property that liquid molecules escape from the liquid surface when heated, and the mean free paths of different kinds of molecules are different after they escape.

The core of short path molecular distillation technology is short path molecular distillation device. In order to achieve the purpose of separation, the liquid mixture is heated first, and molecules with sufficient energy escape the liquid surface.The mean free path of light molecules is large, and the mean free path of heavy molecules is small.

A trap is set at a place greater than the mean free path of the heavy molecules, so that the light molecules are continuously captured, thereby destroying the dynamic balance of the light molecules and causing the light molecules in the mixed liquid to continue to escape, and the heavy molecules cannot be captured. The device quickly tends to dynamic equilibrium and no longer escapes from the mixed liquid, so that the liquid mixture achieves the purpose of separation. In the structural design of the short path molecular distillation device, the mass transfer efficiency in the liquid surface and the distance between the heating surface and the trap surface must be fully considered.

Advantages of short path molecular distillation:

1. Short heating time

In view of the fact that short path molecular distillation is separated based on the difference in the free path of the molecules of different substances, the distance between the heated surface and the condensing surface is smaller than the free path of light molecules (that is, the distance is very short), so the light escaping from the liquid surface The molecules reach the condensation surface almost without collision, so the heating time is very short. In addition, if a more advanced short path molecular distillation structure is used to make the liquid surface of the mixed liquid reach a film shape, and the area of the liquid surface and the heating surface are almost equal at this time, the distillation time at this time is shorter.

2. Low operating temperature

Conventional distillation relies on the boiling point difference of different substances for separation, while short path molecular distillation relies on the movement of molecules of different substances.

Separation is carried out by the difference of the process, therefore, the latter is operated far (far below) the boiling point.

3. Low distillation pressure

4. High degree of separation

Disadvantages of short path molecular distillation:

The price of short path molecular distillation equipment is higher than that of transmission distillation equipment. When using short path molecular distillation equipment, the pressure of the system must be guaranteed to reach a high vacuum degree, the material sealing requirements are high, and the distance between the evaporation surface and the condensation surface should be moderate, resulting in equipment The processing is difficult and the cost is high.

Difference Between Short Path Distillation and Short Path Molecular Distillation

Short path distillation and short path molecular distillation are both advanced techniques used for the separation and purification of liquids. While they have similarities, there are important differences between the two processes.

1. Principle of Operation:

- Short Path Distillation: In short path distillation, the liquid mixture is heated in a flask and then vaporized. The vapors are condensed and collected in a separate flask, resulting in the separation of components based on their boiling points. The condensed vapors generally undergo a single evaporation-condensation cycle.

- Short Path Molecular Distillation: Short Path Molecular distillation, also known as molecular vacuum distillation, operates under high vacuum conditions. The liquid mixture is heated in a short path evaporator, where the pressure is significantly reduced. This low-pressure environment allows for the separation of components with very close boiling points. The condensed vapors undergo multiple evaporation-condensation cycles in order to achieve higher purification levels.

2. Operating Conditions:

- Short Path Distillation: Short path distillation typically operates at moderate vacuum levels and higher temperatures. The vacuum level is usually in the range of 1-10 mbar, and the temperatures employed are higher, typically between 100-200°C.

- Short Path Molecular Distillation: Short Path Molecular distillation requires much higher vacuum levels, often in the range of 0.001-0.1 mbar, to enable the separation of components with similar boiling points. It operates at lower temperatures compared to short path distillation, usually between 50-150°C, which minimizes thermal degradation of the desired product.

3. Separation Efficiency:

- Short Path Distillation: Short path distillation provides effective separation of components with distinct boiling points. However, it may not be as efficient when dealing with compounds that have very close boiling points or heat-sensitive substances.

- Short Path Molecular Distillation: Short Path Molecular distillation excels in separating components with extremely close boiling points. The short residence time and multiple evaporations-condensation cycles achieved in short path molecular distillation enhance the separation efficiency, making it suitable for heat-sensitive substances or complex mixtures.

4. Equipment Design:

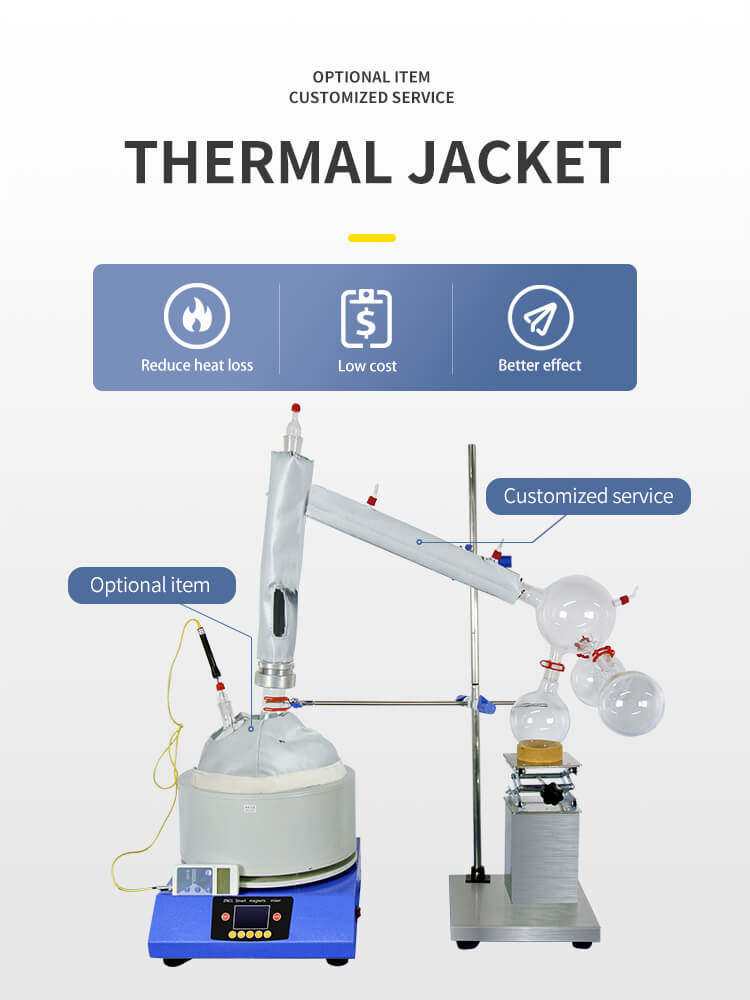

- Short Path Distillation: Short path distillation systems typically consist of a flask for heating the liquid mixture, a short path condenser for vapor condensation, and separate collection flasks for different fractions. The path length between the heating flask and condenser is relatively short.

- Short Path Molecular Distillation: Short Path Molecular distillation systems have a more complex design. They incorporate a short path evaporator with a long, cylindrical body and a high surface area to volume ratio, enabling efficient separation. Additionally, short path molecular distillation systems often include additional components such as internal condensers and fractionating chambers.

Short path distillation is suitable for separating components with distinct boiling points, while short path molecular distillation is more effective when dealing with components that have very close boiling points or heat-sensitive substances. Short path molecular distillation operates under higher vacuum levels, lower temperatures, and employs multiple evaporations-condensation cycles, resulting in higher separation efficiency.