Latest glass reactors - buying guide

100l glass reactor play the role of reaction materials in laboratory instruments, and are often selected by industries such as modern fine chemicals, biopharmaceuticals, and scientific research experiments. Among the glass reactors used, there are double-layer glass reactors, single-layer glass reactors, and high-pressure reactors. These reaction kettles also have explosion-proof and non-explosion-proof functions. In fact, from the actual use situation, very few explosion-proof glass reaction kettles are used. Unless the material safety requirements of the reaction are very high, an explosion-proof glass reactor must be used. Generally, we choose these ordinary single-layer or double-layer glass reactors.

Precautions for using glass reactor:

1. It is not suitable to run at high speed with no load;

2. Keep the speed regulation and the motor dry, because the life of the electrical box has a great influence on the surrounding humidity and temperature;

3. The ground wire must be well grounded, and the high temperature bath must be connected to the air switch;

4. Electric shock may still occur within 5 minutes after the power is cut off, due to the discharge of the inverter or capacitor;

5. Please avoid the impact damage to the glass by hard objects such as watches and rings when operating the instrument;

6. When the glass reactor needs to be heated, the temperature should be gradually increased, especially when heated at high temperature, it is generally recommended to use heat transfer oil that is less harmful to the human body.

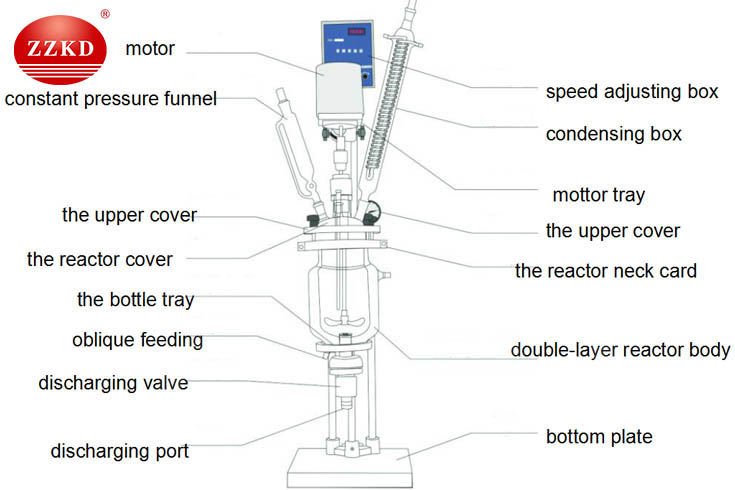

Glass reactor structure diagram:

Next, we will introduce the latest glass reactors in 2022:

1.S-50L double-layer glass reactor

S-50L double-layer glass reaction kettle has a volume of 50L of reaction bottle, a capacity of 12L of interlayer, a diameter of stirring shaft of 12mm, and a stirring power of 120W. S-50L is a product of our company's existing glass reactor series that combines the advantages of similar foreign and domestic products, and is a bold and innovative product. It adopts double-layer glass design. The cold and heat sources (refrigerated liquid, hot water or hot oil) are used for cyclic heating or cooling reactions. Under the set constant temperature, in a closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and the reaction solution can be refluxed and distilled. It is a modern fine chemical, biopharmaceutical and new Ideal pilot and production equipment for material synthesis. The main parts of this series of reactors are: double-layer glass reactor body, a set of glass reactor components cover, condenser, constant pressure funnel, frequency conversion controller, rotary stirring and sealing system, stainless steel frame system, etc.

Product advantages:

1. Constant speed, no brushes, no sparks, safe and stable, and can work continuously.

2. The whole set of glass instruments is produced by G3.3 borosilicate glass, which has good chemical and physical properties.

3. The PTFE components are sealed to maintain a high degree of vacuum.

2.S-20L double-layer glass reactor

S-20L double-layer glass reaction kettle has a volume of 20L of reaction bottle, a capacity of 8L of interlayer, a stirring shaft diameter of 12mm, and a stirring power of 90W. S-20L is a bold and innovative product in Lanphan's existing glass reactor series that combines the advantages of similar foreign and domestic products. It is designed with double-layer glass. The inner layer can be stirred and reacted by adding reaction solvent, and the interlayer can pass through different The cold and heat sources (refrigerated liquid, hot water or hot oil) are used for cyclic heating or cooling reactions. Under the set constant temperature, in a closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and the reaction solution can be refluxed and distilled. It is a modern fine chemical, biopharmaceutical and new Ideal pilot and production equipment for material synthesis. The main parts of this series of reactors are: double-layer glass reactor body, a set of glass reactor components cover, condenser, constant pressure funnel, frequency conversion controller, rotary stirring and sealing system, stainless steel frame system, etc.

Product advantages:

1. Constant speed, no brushes, no sparks, safe and stable, and can work continuously.

2. The whole set of glass instruments is produced by G3.3 borosilicate glass, which has good chemical and physical properties.

3. The PTFE components are sealed to maintain a high degree of vacuum.

3.F-10L single-layer glass reactor

The maximum capacity of the F-10L single-layer glass reactor is 10L, and the maximum speed during operation can reach 450rpm. Because the volume of the reaction bottle is 10L, it is called the F-10L single-layer glass reactor, also known as: glass vacuum Reactor, Extractor, Multifunctional Reactor. As a multifunctional reactor, F-10L single-layer glass reactor can carry out various biochemical synthesis reactions under constant temperature conditions, and can also do reflux or distillation at different temperatures. The reaction part of the instrument is a controllable and fully sealed structure, which can use negative pressure to continuously inhale various liquids and gases, and can also do filling or distillation at different temperatures.

Product advantages:

1. Constant speed, no brushes, no sparks, safe and stable, and can work continuously.

2. The whole set of glass instruments is produced by G3.3 borosilicate glass, which has good chemical and physical properties.

3. The PTFE components are sealed to maintain a high degree of vacuum.

4.F-50L single-layer glass reactor

The maximum capacity of the F-50L single-layer glass reactor is 50L, and the maximum speed can reach 600rpm during operation. Because the volume of the reaction bottle is 50L, it is called the F-50L single-layer glass reactor, also known as: glass vacuum Reactor, Extractor, Multifunctional Reactor. As a multifunctional reactor, F-50L single-layer glass reactor can carry out various biochemical synthesis reactions under constant temperature conditions, and can also do reflux or distillation at different temperatures. The reaction part of the instrument is a controllable and fully sealed structure, which can use negative pressure to continuously inhale various liquids and gases, and can also do filling or distillation at different temperatures.

Product advantages:

1. Constant speed, no brushes, no sparks, safe and stable, and can work continuously.

2. The whole set of glass instruments is produced by G3.3 borosilicate glass, which has good chemical and physical properties.

3. The PTFE components are sealed to maintain a high degree of vacuum.

Package product:

1.SHZ circulating water vacuum pump.

2.DLSB-50 series low temperature coolant circulation pump.

Common problem:

1. Q: What is the difference between a single-layer glass reactor and a double-layer glass reactor?

A: The single-layer glass reactor can be directly heated and cooled, similar to the oil bath and water bath, but the effect of temperature control is not ideal. There is an interlayer between the two layers of the double-layer glass reactor, and water or oil can be input through the temperature control device to form a cycle, so that the temperature control will be better and more accurate regardless of whether it is cooling or heating.

2. Q: In what circumstances are they applicable?

A: It can be used in high temperature areas from 200 degrees Celsius to low temperatures of minus 80 degrees Celsius.

3. Q: What types of double-layer glass reactors are there?

Answer: Our model is the most complete glass reactor manufacturer on the market. The double-layer glass reactors include S-1L, S-2L, S-3L, S-5L, S-10L, S-20L, S-25L , S-30L, S-50L, S-100L.

Single-layer glass reactors include F-1L, F-2L, F-3L, F-5L, F-10L, F-20L, F-30L, F-50L, F-100L.

4. Q: What is the glass material of the glass reactor?

A: The whole set of glass instruments of the glass reactor are produced with G3.3 borosilicate glass, which has good chemical and physical properties.

5. Q: What is the material of the glass reactor machine?

Answer: The main materials of the glass reactor are stainless steel and aluminum alloy.

6. Q: Is the glass reactor explosion-proof?

Answer: There are explosion-proof glass reactors, but the cost is more expensive than non-explosion-proof glass reactors

The above is the use method and advantages of the rotary evaporator we introduced this time. If you have any needs, you can contact Zhengzhou Keda Machinery Equipment Co., Ltd. For decades, Zhengzhou Keda Machinery Equipment Co., Ltd. has been committed to the production and manufacture of laboratory instruments and pipe fittings. If you want to know about our products, or are interested in purchasing our instruments, please contact us, we will be happy to help you.