- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

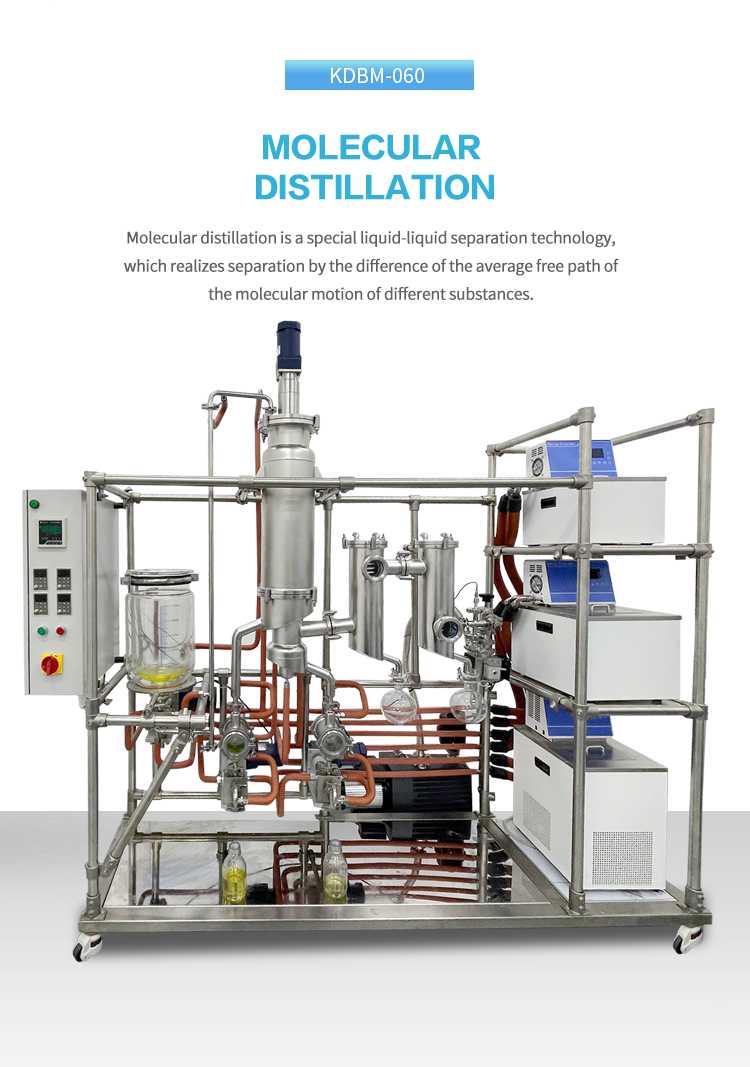

The stainless steel molecular distillation apparatus can be used to purify molecules with poor thermal stability and related compounds with low volatility and high boiling points. In a high vacuum environment, molecular distillation is characterized by low distillation temperature, short heating time of materials, and rapid separation. It is widely used in various fields such as CBD extraction, petrochemical industry, pharmaceutical chemical industry, essential oil extraction, cosmetics and perfume purification.

1. Distillation system is all stainless steel, not easy to break

2. Made of stainless steel, high borosilicate glass, etc., good anti-corrosion ability

3. Fast evaporation, high efficiency, high extraction purity

4. The inner wall is smooth and will not stick to materials and scale

5. Accurate temperature control, the maximum temperature can reach 300°C

6. Frequency conversion motor, with its own heat dissipation function, can run continuously for a long time

7. The maximum vacuum degree can reach 0.0001m

8. Fast heating speed, fast cooling speed

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

What is the working principle of molecular distillation?

Molecular distillation can obtain pure and safe products, and the operation process is simple. Molecular distillation technology can separate substances that are not easily separated by conventional distillation. It is required that the distillation device must ensure a high vacuum that the system pressure can reach. It has high requirements for material sealing, and the distance between the evaporation surface and the condensation surface should be moderate. The equipment processing is difficult. The cost is high. The energy consumption of stainless steel molecular distillation products is small, because the entire separation of molecular distillation loses less overheating, due to the special structure of the stainless steel molecular distillation instrument, the internal pressure is extremely low and the internal resistance is much smaller than that of conventional distillation. It is equipped with a three-layer cold trap with a window structure. The cold trap with sleeve structure, the air inlet and the air outlet are at the same height, and the internal flow channel forces the gas flow direction to ensure sufficient contact between the gas and the strong cold surface, which can greatly save energy.

What is the distillation process of molecular distillation equipment?

The material is added from the top of the evaporator and is continuously and evenly distributed on the heating surface through the liquid distributor. The film-scraping device turns the liquid material into a very thin liquid film and advances downward spirally. In this process, the liquid derived from the heating device reaches the built-in condenser, flows along the condenser tube, and is discharged through the exhaust pipe at the bottom of the evaporator. The residue is collected below the heating zone and flows out from the side of the tube.

What systems are included in a set of molecular distillation equipment?

A complete set of molecular distillation equipment includes: molecular evaporator, degassing system, feeding system, heating system, cooling system and vacuum control system.

○ PARAMETER ○ | ||||||

Model | BM-60 | BM-80 | BM-100 | BM-150 | BM-200 | BM-230 |

Main evaporator diameter (mm) | 60 | 80 | 100 | 150 | 200 | 230 |

Effective evaporation area (m2) | 0.06 | 0.1 | 0.15 | 0.25 | 0.35 | 0.5 |

Feeding speed (kg / h) | 0.5-3 | 1-5 | 2-8 | 3-15 | 5-20 | 8-30 |

Feed tank volume (L) | 1 | 1 | 2 | 2 | 5 | 5 |

Maximum speed (R / min) | 450 | 450 | 450 | 450 | 300 | 300 |

Volume of collecting bottle (L) | 1 | 1 | 2 | 3 | 5 | 5 |

Motor power (W) | 90 | 120 | 120 | 120 | 200 | 200 |

Operating temperature (℃) | -90~220 | |||||

Voltage (V/Hz) | 220/50 (The voltage can be customized) | |||||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap