- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Advantage:

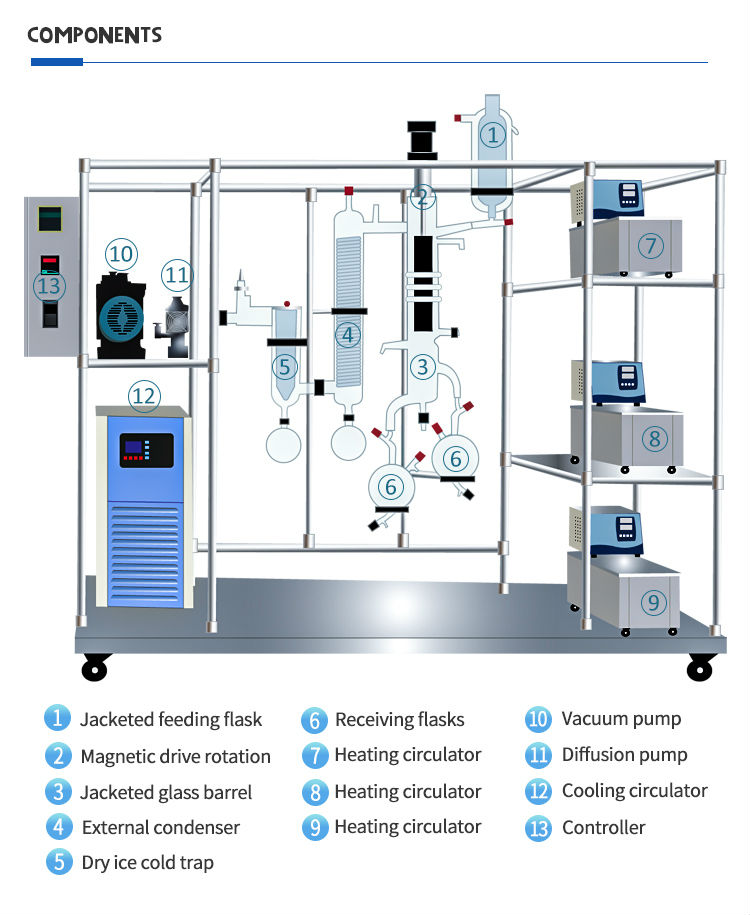

The molecular distillation system is made of high borosilicate glass, stainless steel and polytetrafluoroethylene. It has excellent corrosion resistance. It can watch the whole process of material feeding, evaporation, separation and discharging. It can be widely used in pharmaceuticals and food. , Petroleum, chemical, environmental protection and other industries.

Features:

1. The maximum vacuum can reach 5Pa or 0.1Pa.

2. Scraper film forming system and self-cleaning drum film forming system can be provided.

3. Adopt pressure-resistant precision gear pump for feeding and discharging, which can realize constant feeding and discharging speed.

4. Wide applicability, after the material enters, it can keep heat all the way.

5. Materials with low viscosity and low boiling point and materials with high viscosity and high boiling point can be separated.

6. The operation is simple, you only need to pour the material into the feed tank and press the button to set the whole process.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

Grouped equipment:

Rotary vane water vacuum pump

Circulating water vacuum pump

Low temperature coolant circulation pump

Circulating water/oil bath

FAQ:

1. What materials are used for the components of the molecular distillation system?

The molecular distillation system is composed of high borosilicate glass, 316L stainless steel and polytetrafluoroethylene, and has excellent corrosion resistance. The maximum theoretical vacuum can reach 5Pa or 0.1Pa.

2. What are the models of your molecular distillation equipment?

KMD-060, KMD-080, KMD-100, KMD-150, KMD-200.

3. What is the reaction process of the molecular distillation system?

Molecules diffuse from the main liquid phase to the evaporation surface;

Free evaporation of molecules on the surface of the liquid layer;

The molecules fly from the evaporation surface to the condensation surface;

The molecules condense on the condensation surface.

Model | KMD-060 | KMD-080 | KMD-100 | KMD-150 | KMD-200 |

Effective evaporation area (m2) | 0.06 | 0.1 | 0.15 | 0.24 | 0.35 |

Barrel diameter(mm) | 60 | 80 | 100 | 150 | 200 |

Feeding funnel volume | 1L | 1.5L | 2L | 2L | 5L |

Feed rate (g/h) | 250-500 | 500-750 | 750-1500 | 1500-3000 | 3000-5000 |

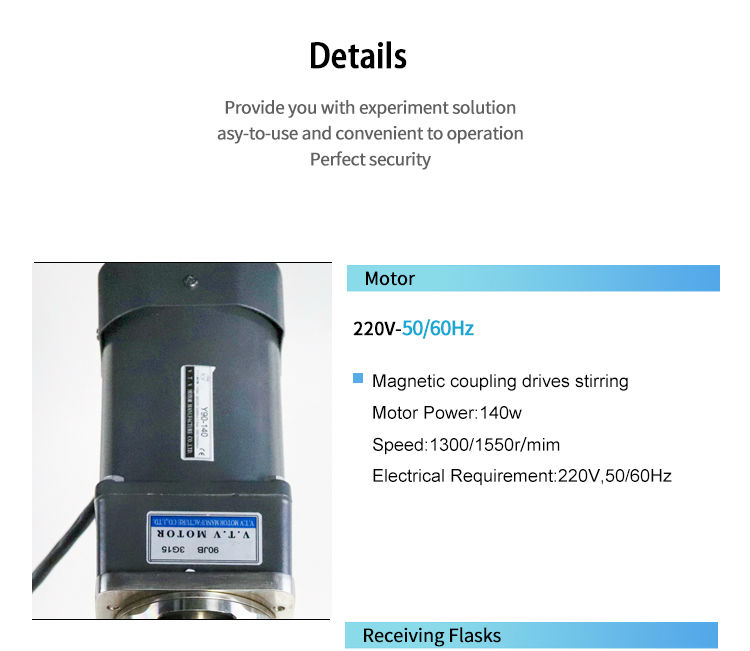

Motor power (W) | 90 | 120 | 120 | 120 | 200 |

Maximum speed (rpm) | 0-500 | ||||

Distillate receiving flask | 1L | 1L | 2L | 3L | 5L |

Recicle receiving flask | 1L | 1L | 2L | 3L | 5L |

Operation temperature | Up to 200℃ | ||||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap