- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

TGYF-B series lab scale high pressure reactor capacity specifications are: 50ml, 100ml, 250ml, 500ml, 1000ml, stirring method: internal magnetic stirring, there is no problem of shaft seal leakage and maintenance, to ensure no leakage, no exposed rotating parts, The experiment is safer. Stirring motor: high-power motor, powerful and stable performance.

·The kettle body and the kettle cover are made of stainless steel. The kettle body is connected to the flange through threads, and the kettle cover is a positive flat cover. The two are fastened and connected by the main bolts and nuts uniformly distributed in the circumferential direction. A barrel-shaped silicon carbide furnace core is installed outside the kettle body, and the electric furnace wire passes through the furnace core, and its end passes through the lower part of the furnace shell side, and is connected to the controller through a connecting stud and a rubber-sheathed cable.

·The main sealing port of the autoclave adopts A-type double-line seal, and the rest of the sealing points adopt the sealing form of line contact between the arc surface and the plane, and between the arc surface and the arc surface. Relying on the high precision and smoothness of the contact surface, good sealing effect.

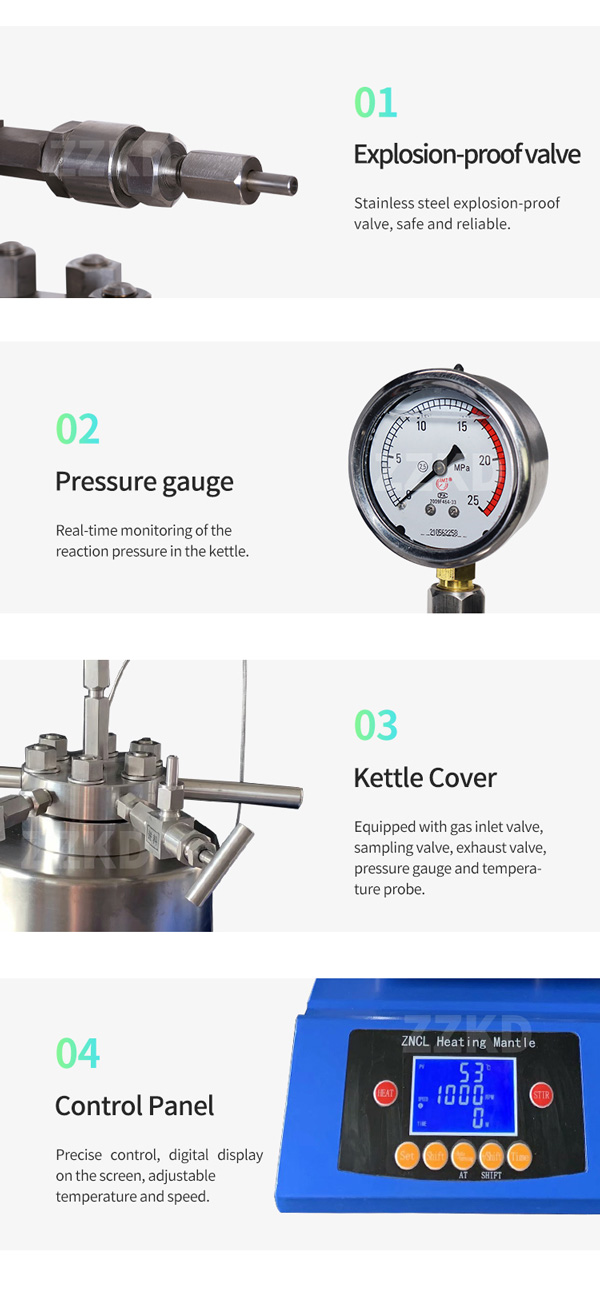

·The lid of the kettle is equipped with a pressure gauge, a bursting membrane safety device, a vapor-liquid phase valve, a temperature sensor, etc., so that it is convenient to know the reaction situation in the kettle at any time, adjust the proportion of the medium in the kettle, and ensure safe operation.

·The coupling is mainly composed of a pair of inner and outer magnetic rings with strong magnetic force, and a pressure-bearing spacer in the middle. The stirrer is driven by a servo motor through a coupling. The purpose of controlling the stirring speed can be achieved by controlling the speed of the servo motor.

·The upper part of the spacer is equipped with a speed measuring coil. When the integrated stirrer and the inner magnetic ring rotate, the speed measuring coil will generate an induced electromotive force, which corresponds to the stirring speed, and the electric potential will be transmitted to the tachometer to display the stirring speed. .

·A cooling water jacket is installed between the magnetic coupling and the lid of the kettle. When the operating temperature is high, the cooling water should be passed through, and the magnetic steel will be demagnetized if the temperature is too high. The bearing is made of stainless steel bearing or high-strength electro-chemical graphite, which is wear-resistant and has a long maintenance period.

Stirring method: Internal magnetic stirring, no shaft seal leakage and maintenance problems, to ensure no leakage, no exposed rotating parts, and the test is safer.

Stirring motor: high-power brushless motor, powerful and stable.

·Gas inlet valve: gas inlet needle valve.

·Sampling valve: It is convenient to take samples at any time during the reaction and analyze the reaction process.

·Exhaust valve: It is convenient to vacuum the system and replace the gas before the reaction, and it is used as a vent valve after the reaction.

·Pressure gauge: real-time monitoring of reaction pressure in the kettle.

·Temperature probe: go deep into the inside of the reactor body to monitor the reaction temperature.

·Heating unit: module heating, fast heating, precise control, digital display on the screen.

·Connection method: The laboratory high-pressure reactor is connected by flanges.

·Before each start-up of the high-pressure reactor in the laboratory, check the valves, switches, power supply and lines, etc. to ensure that there are no problems. Before starting the machine, turn on the stirring cooling water (a separate cooling water system must be used). During operation and when the temperature is high, the cooling water must be kept on to prevent high-temperature demagnetization of the inner rotor.

·After the feeding is completed, set the process parameters according to the specified process conditions and start the machine to work. The working parameters of the high-pressure reactor cannot exceed the rated technical parameters.

·The lab scale high pressure reactor must not be idling under any circumstances; when the speed is greater than 100r/min, the stirring motor must not be started at the working speed to prevent the current from overshooting and damaging the controller; the speed should be adjusted by the speed control knob or frequency conversion Slowly increase the operating speed.

·After each work is finished, each switch should be turned off, and the knobs should be reset to zero, so as to prevent the controller from burning out due to current overshoot due to misoperation in the next use.

··When the lab scale high pressure reactor heats up or cools down, the operation action must be stable, so as to avoid the sudden superimposition of temperature difference stress and pressure stress, which will cause deformation or damage to the equipment; especially the stirring speed, only allowed to increase slowly. In case of power failure, the speed control knob should be adjusted back to zero.

·When the lab scale high pressure reactor is in operation, a special person shall be assigned for each shift, and the operator shall not leave the workbench. Strictly implement the shift management system, include equipment operation and integrity in the shift, and reduce abnormal situations and equipment accidents due to unclear shifts.

·The equipment that needs to be lubricated should be filled with grease according to the regulations, and the internal and external parts of the kettle should be checked regularly, and the relevant parts should be replaced if necessary.

Model | TGYF-B | |||

Volume | 50ml | 100ml | 250ml | 500ml |

Pressure | 22MPa | |||

Temperature | 350℃ | |||

Stirring speed | 0-1800 r/min | |||

Heating power | 0.6kW | 0.6kW | 0.8kW | 1.5kW |

Heating mode | Modular electrical heating | |||

Stirring method | Magnetic stirring at the bottom | |||

Material | Stainless steel 304, 316 | |||

Display method | Screen digital display | |||

Connection mode | flange connection | |||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap