- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Advantage:

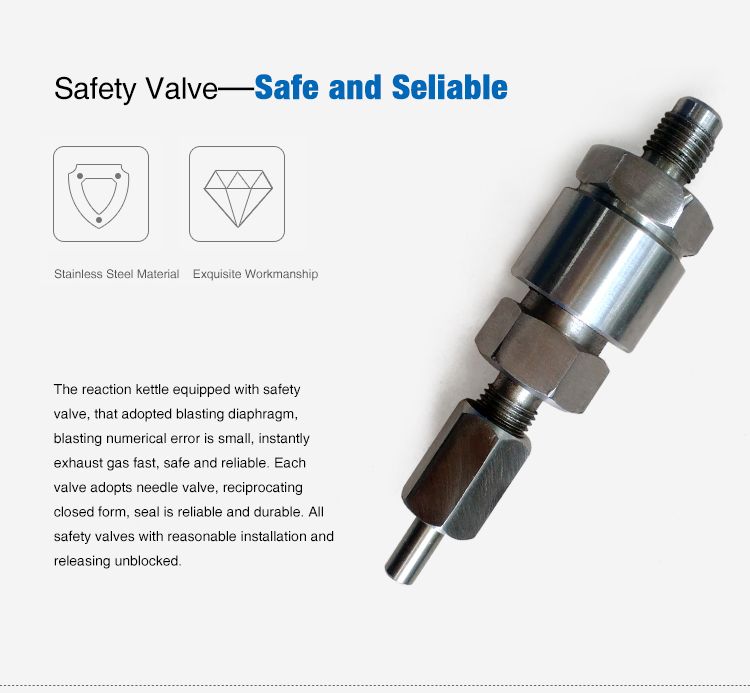

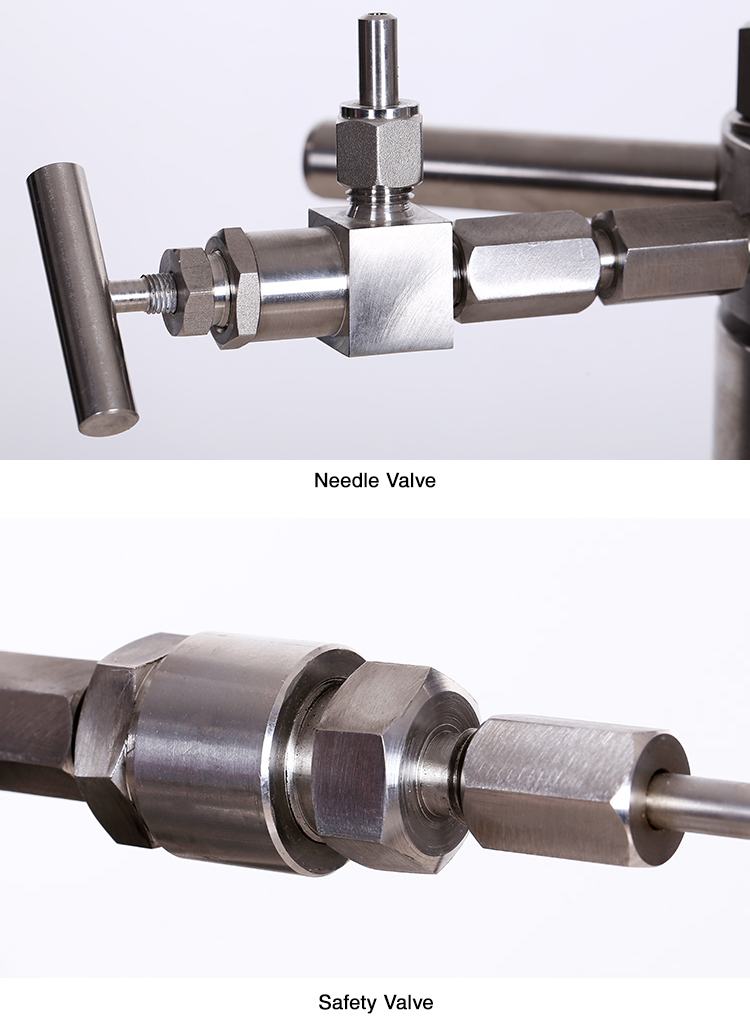

Stainless steel simple high-pressure reactor is a simple high-pressure reactor produced according to customer requirements according to the functional characteristics of the autoclave. It can be placed in stainless steel such as electric blast drying furnace, constant temperature oil/water bath, low temperature tank, etc. Small simple high pressure reactor system autoclave is suitable for mixing flammable, explosive, highly toxic, precious media and strong permeability chemical media. It is the best non-leakage reaction for vulcanization, fluorination and oxidation of petroleum, chemical industry, organic synthesis, polymer, food and other processes.

Features:

1. The body and lid of the kettle are made of high-quality stainless steel. The simple stainless steel high-pressure reactor body is connected with flanges through threads.

2. Has a good sealing effect.

3. The temperature can be controlled by PID temperature control system.

4. Cooling rate ≤5°C/min. The safety pressure is 22 MPa.

5. Beautiful appearance, reasonable structure and simple operation.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

1. What are the models of Small simple high pressure reactor?

CF-0.025,CF-0.05,CF-0.1,CF-0.2,CF-0.3,CF-0.5,CF-1,CF-2,CF-3,CF-5,CF-7,CF-10,CF- 20 and so on.

2. What are the uses of Small simple high pressure reactor?

The main feature of the stainless steel high-pressure reactor is the static sealing structure, which uses static sealing instead of dynamic sealing. The stirrer and the motor drive are connected by a magnetic coupler. The non-contact torque transmission completely solves the problem of poor sealing of materials during direct stirring. The entire medium and stirring part are completely sealed. The stainless steel high-pressure reactor is more suitable for all kinds of flammable, explosive, highly toxic, precious media and other chemical media with strong permeability. It is a process of petroleum, chemistry, organic synthesis, polymer material polymerization, and food. The most ideal non-leakage reaction equipment for vulcanization, fluorination, hydrogenation, etc.

Model | Volume(L) | DesignedPressure(Mpa) |

CF-0.025 | 0.025 | 22 |

CF-0.05 | 0.05 | 22 |

CF-0.1 | 0.1 | 22 |

CF-0.2 | 0.2 | 22 |

CF-0.25 | 0.25 | 22 |

CF-0.3 | 0.3 | 22 |

CF-0.5 | 0.5 | 22 |

CF-1 | 1 | 22 |

CF-2 | 2 | 22 |

CF-3 | 3 | 22 |

CF-5 | 5 | 22 |

CF-7 | 7 | 22 |

CF-10 | 10 | 22 |

CF-20 | 20 | 22 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap