- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

The blast drying oven laboratory is used for drying, baking, melting wax, and sterilizing items; it is suitable for industrial and mining enterprises, scientific research institutes, colleges and universities, medical and health units, etc. The blast drying oven laboratory adopts a digital temperature regulator to control the temperature, which is sensitive and accurate, and easy to operate. There is an air inlet hole at the bottom of the working room, and an exhaust valve is installed on the top of the box. Cold air enters from the bottom of the box and is discharged from the top of the box. It is equipped with wind stirring to make the temperature field more uniform.

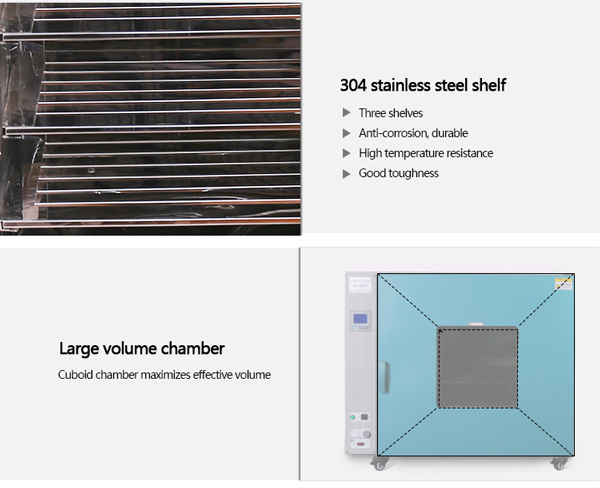

· The laboratory box of the blast drying oven is made of high-quality steel plates, and the studio is made of 304 stainless steel plates, which are beautiful in shape and novel.

· Microcomputer intelligent temperature controller, with dual digital display for setting and measuring temperature, timing, power suppression and PID self-tuning functions, accurate and reliable temperature control.

· The hot air circulation system is composed of a fan that can operate continuously at high temperature and a suitable air duct, so that the temperature in the working room is uniform.

· The over-temperature alarm system will stop immediately if the temperature exceeds the limit, and the sound and light alarm will prompt the operator to ensure the safe operation of the experiment without accidents.

· The blast drying oven laboratory adopts a new type of rubber sealing strip, which can run at high temperature for a long time, has a long service life and is easy to replace.

· The product studio is made of stainless steel with an observation window. It can be equipped with an embedded printer, which can print and record the temperature at different times, which is convenient for querying the temperature control situation in the whole process; or RS485 communication interface, which is convenient for connecting to a printer or computer (optional).

· Programmable LCD touch controller, can set multi-segment program control, multiple parameters can be displayed on one screen, easy to operate, easy to edit programs (optional).

· The blast drying oven laboratory can be equipped with a SMS monitoring and alarm system. If the user is not on site and the equipment fails, the system collects the fault signal in time and sends it to the mobile phone of the designated recipient through SMS to ensure timely troubleshooting and resume testing to avoid accidental losses (optional).

In order to prolong the service life of the electric blast drying oven, we must understand the daily maintenance knowledge of the electric blast drying oven.

1. Clean the surface and the dust in the laboratory studio of the blast drying box to keep the drying box clean and hygienic.

2. Regularly check whether the fan in the laboratory of the blast drying oven is running normally and whether there is any abnormal sound. If there is any abnormal sound, turn off the machine immediately for inspection.

3. Regularly check whether the laboratory vent of the blast drying oven is blocked, and regularly clean up the accumulated dust.

4. Regularly check whether the temperature controller of the blast drying oven laboratory is accurate, if not, please adjust the static compensation of the temperature controller or the correction value of the sensor.

5. Regularly check whether the heating tube is damaged and whether the circuit is aging.

6. In the event of a sudden power failure, the power switch and heating switch of the laboratory blast drying oven should be turned off to prevent automatic startup when the power comes in.

Diaphragm vacuum pump

Rotary Vane Vacuum Pump

When the hot air in the drying room heats the material, the moisture will become water vapor and mix into the hot air. The air in the drying room is convectively circulated through the fan, and then the hot air with water vapor is discharged through the exhaust hole. The moisture is also taken out of the drying room to achieve the purpose of drying.

The set temperature is too low, the thermometer output circuit wiring is closed, the thermostat has no output signal, the heater is damaged, the timer is started, or the setting is incorrect.

The blast drying oven produced by our company can be equipped with rotary vane vacuum pump and diaphragm pump. Please contact us for specifications.

Heat transfer oil, steam heating and electric heating, etc. Of course, the most commonly used is electric heating.

Model | DHG-9420A |

Power Supply | 220V/50Hz |

Shell Material | Spray-paint Anti-corrosion |

Liner Material | 304 Stainless Steel |

Temp. Range | RT+10~250°C |

Temp. Stability | ±1.0°C |

Temp.Analysis | 0.1°C |

Working Temp. | +5~40°C |

Input Power (W) | 3500 |

Chamber Capacity (L) | 393 |

Inner Dimension (W*D*H, mm) | 750*750*700 |

Overall Dimension (W*D*H, mm) | 1050*950*920 |

Shelves (Pcs) | 3 |

Time Range | 1~9999 min |

Optional Configuration | EX |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap