- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

The precision blast drying oven uses direct heating and is assisted by blower fan exhaust. The drying principle is to heat the molecules of moisture, solvents or volatile components in the material, so that the molecules move quickly and gradually separate from the dry material. Allow the material to dry. This drying method has fast speed and high temperature. Under the action of the fan, the precision blast drying box can quickly take away the volatile substance molecules volatilized from the surface of the material through air exchange, so as to achieve the effect of rapid drying of the material.

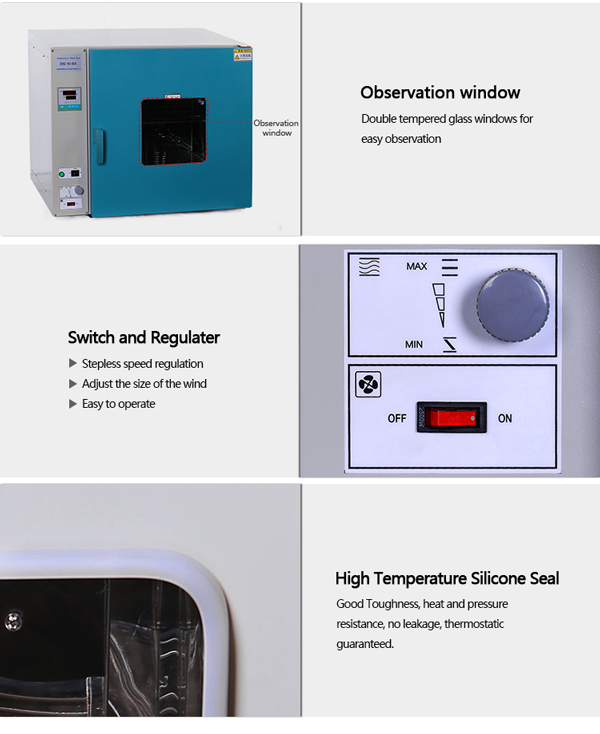

1. The inside of the box is made of mirror stainless steel argon arc welding, and the outside of the box is made of high-quality steel plate, which is beautiful and novel.

2. Adopt microcomputer P.I.D temperature controller with over-temperature deviation protection and digital display, with timing function, the temperature is accurate and reliable.

3. The hot air circulation system is composed of a fan that can operate continuously at high temperature and a suitable air duct to improve the uniform temperature in the working room.

4. The precision blast drying oven adopts a new type of synthetic silicon sealing strip, which can run at high temperature for a long time, has a long service life and is easy to replace.

5. The precision blast drying oven can adjust the air intake and exhaust volume in the oven from the temperature control panel.

6. Independent temperature limit alarm system, which will be automatically interrupted when the temperature exceeds the limit, so as to ensure the safe operation of the experiment without accidents. (optional)

7. It can be equipped with a printer or RS485 interface for connecting to a printer or a computer, and can record changes in temperature parameters. (optional)

1. The precision blast drying oven is used for melting, drying or other heating of samples. The maximum working temperature is 300°C. The drying box works under the condition that the ambient temperature is not higher than 40°C and the relative air humidity is not higher than 85%.

2. The precision blast drying box uses a special plug and socket, and grounds with a wire twice as thick as the power cord. Check the electrical insulation performance before use, and pay attention to whether there are open circuit, short circuit and leakage.

3. Put a thermometer on the precision blast drying box, turn on the power and adjust the temperature control knob to the set temperature, and check whether the reading of the thermometer is consistent with the set value when the AC contact switch is just disconnected. If there is any discrepancy, fine-tune it until The thermostatic temperature matches the set temperature.

4. Open the top or bottom vent to remove the moisture in the box.

5. The maximum average load of the steel plate for the test sample is 15Kg. Do not place it too heavy or too dense. There must be gaps. The test sample cannot be placed on the bottom plate of the studio.

6. It is strictly forbidden to put flammable and volatile items in the drying box to prevent explosion.

7. Turn on the power supply, the green indicator light is on, turn on the blower switch, the blower motor runs, turn on the heating power supply, and the drying box enters the working state.

8. When the precision blast drying oven is working, the door should not be opened frequently, so as not to affect the constant temperature field.

9. This equipment does not have an over-temperature protection device, so a special person should monitor the temperature inside the box during work. Once the temperature is out of control, the power should be cut off and checked in time to avoid accidents.

1. Double-layer tempered glass door, two layers inside and outside, beautiful and generous.

2.1-9999min timing range.

3. High-quality stainless steel electric heating tube, uniform heating and long service life.

4. The silicone door sealing ring is integrally formed to ensure a high vacuum in the studio.

5. The temperature control range can reach RT+10 ~ 250 ℃.

Diaphragm vacuum pump

Rotary Vane Vacuum Pump

The set temperature is too low, the thermometer output circuit wiring is closed, the thermostat has no output signal, the heater is damaged, the timer is started, or the setting is incorrect.

DHG-9140A, DHG-9030A, DHG-9420A, DHG-9070A.

Temperature setting range: -RT+10~300.0℃; basic error of temperature measurement:

When the hot air in the drying room heats the material, the moisture will become water vapor and mix into the hot air. The air in the drying room is convectively circulated through the fan, and then the hot air with water vapor is discharged through the exhaust hole. The moisture is also taken out of the drying room to achieve the purpose of drying.

Model | DHG-9140A |

Power Supply | 220V/50HZ |

Shell Material | Spray-paint Anti-corrosion |

Liner Material | 304 Stainless Steel |

Temp. Range | RT+10~250°C |

Temp. Stability | ±1.0°C |

Temp. Analysis | 0.1°C |

Working Temp. | '+5~40°C |

Input Power (W) | 1550 |

Chamber Capacity (L) | 151 |

Inner Dimension (W*D*H,mm) | 550*500*550 |

Overall Dimension (W*D*H,mm) | 830*800*720 |

Shelves (Pcs) | 2 |

Time Range | 1~9999 min |

Optional Configuration | Explosion-proof |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap