What is vacuum drying oven

The vacuum drying oven is mainly used for heating by electricity, hot air, etc., using the principles of heat conduction, convection or radiation to transfer heat from the outside to the inside of the material. Vacuum drying ovens have a wide range of uses in the food, pharmaceutical, chemical and other industries. Various vacuum drying oven facilities have been developed and introduced in China, and their structure methods are changeable. In the food industry, the main methods used are box vacuum drying ovens, vertical vacuum drying ovens and so on.

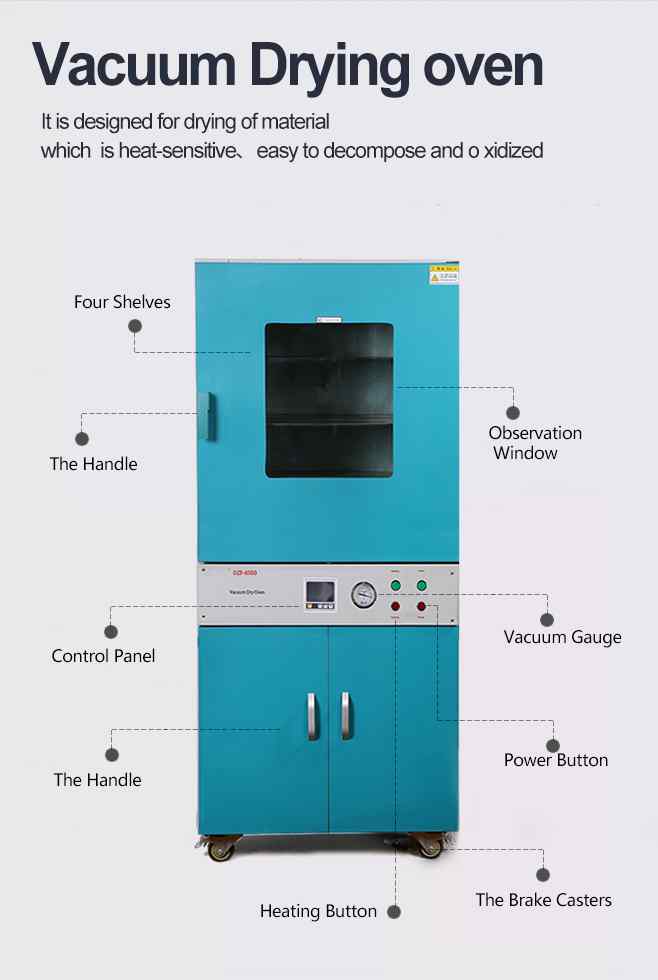

Vacuum drying ovens are widely used in biochemistry, chemical and pharmaceutical, medical and health, agricultural scientific research, environmental protection and other research applications, for powder drying, baking, and disinfection and sterilization of various glass containers. It is especially suitable for fast and efficient drying treatment of dry heat sensitive, easily decomposed, easily oxidized substances and complex composition items.

The basic principle of the vacuum drying oven: Under vacuum conditions, the boiling point of water is reduced. Operating in a vacuum can prevent damage to nutrients and vitamins at high temperatures, and at the same time increase the drying speed. In a vacuum system, the content of air per unit size is lower than that in the atmosphere. Under the background of relatively lack of oxygen, food drying can slow down or even prevent the oxidation of fat in the food, pigment browning or other oxidative deterioration, etc. Therefore, use vacuum drying to obtain better food quality.

Advantages of vacuum drying oven

1. Vacuum drying has a high utilization efficiency. For samples that are not easy to dry, such as powder or other granular samples, the vacuum drying method can reduce the drying time;

2. The vacuum drying oven can easily be used for heat-sensitive materials, because the vacuum environment greatly reduces the boiling point of the liquid that needs to be driven off.

3. It is suitable for drying various mechanical parts with complex structure or other porous samples. After cleaning, vacuum drying method is used, and no residual material is left after drying;

4. It is safer to use-under vacuum or inert conditions, no oxide will explode when exposed to heat;

5. Compared with ordinary drying which relies on air circulation, powdered samples are easy to control and will not be blown or moved by flowing air;

6. Control features: If the power fails, the data of the crash state is lost, the device has the function of protecting parameter memory and call recovery.