Short path distillation working principle

Short path distillation also called molecular distillation, is a continuous distillation process carried out under high vacuum. The short path distillation process is different from the traditional distillation process. The traditional distillation is carried out at the boiling temperature. The evaporation and condensation process is reversible, and the liquid phase and the vapor phase will form an equilibrium state. The short-path distillation process is an irreversible distillation process carried out at a temperature away from the normal pressure boiling point of the substance. More precisely, it is a short-path evaporation process.

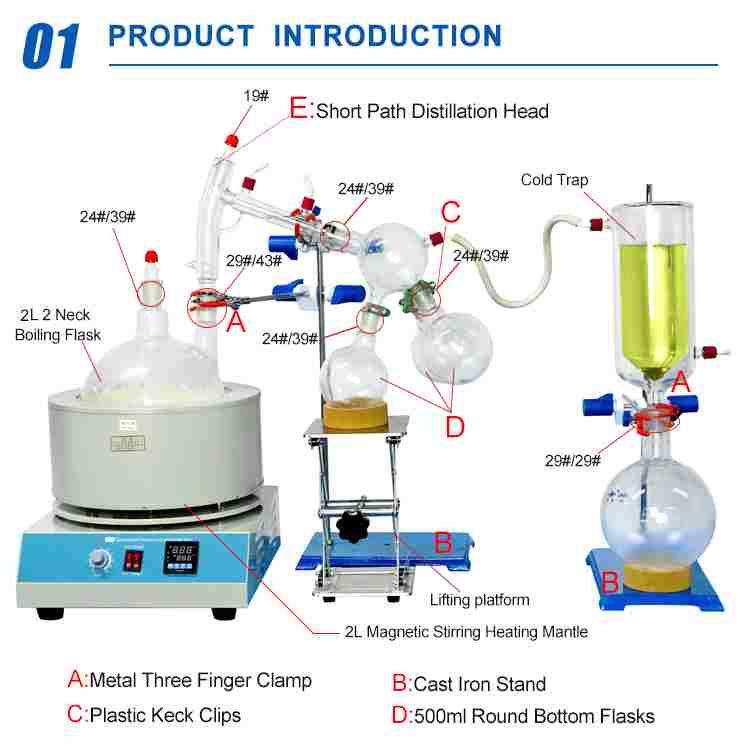

The working principle and composition of short-path distillation:

1. It is a kind of equipment for distillation method operating under high vacuum. There are three types of short-path distiller according to the form of film scraper: rolling film, sliding film scraping, hinge scraping film. Different film scrapers are selected according to the viscosity and processing properties of the material.

2. The pressure difference between the boiling film and the condensing surface is the driving force of the steam flow, and a slight pressure drop will cause the steam to flow. Operation under the standard requires a very short distance between the boiling surface and the condensation surface.

3. A distiller based on this principle is called a short-path distiller. The short path distiller (molecular distillation) has a built-in condenser on the opposite side of the heating surface and reduces the operating pressure to standard pressure.

4. Short path distiller is a process of thermal separation technology that works under standard pressure. Its lower boiling temperature is very suitable for heat sensitive and high boiling point substances.

5. Its basic composition: a cylindrical barrel with heating jacket, a rotor and a built-in condenser; a film wiper and anti-splash device are accurately installed on the rotor's fixed frame. The built-in condenser is located in the center of the evaporator, and the rotor rotates between the cylindrical barrel and the condenser.

6. The short-path distiller is composed of an externally heated vertical cylinder, a central condenser located in it, and a film wiper rotating between the distiller and the condenser.

7. The distillation process of molecular short-path distillation is: the material is added from the top of the evaporator, and it is continuously and evenly distributed on the heating surface through the material liquid distributor on the rotor, and then the film wiper scrapes the material liquid into a very thin layer. It is a turbulent liquid film that advances downward in a spiral shape.

8. In this process, the light molecules escaping from the heating surface are condensed into liquid on the built-in condenser through a short route and almost without collision, and flow down the condenser tube, passing through the outlet at the bottom of the evaporator. The material pipe is discharged; the residual liquid, the heavy molecules, is collected in the circular channel under the heating zone, and then flows out through the side discharge pipe.

The scope of application of short path distillation is the scope of application:

1. Fine chemicals: such as aromatic oil purification, polymer intermediate purification, lanolin extraction, etc.;

2. Medical field: such as extracting natural vitamin AE, synthetic amino acid and glucose derivatives;

3. Food industry: such as refining fish oil, deacidification, refining higher alcohol, and separating mixed oil;

4. Other fields: petroleum industry, chemical industry, environmental protection.