High Pressure Lab Reactor: Advancements and Applications

In the realm of chemical and material science research, the utilization of High pressure reactor manufacturers has emerged as a cornerstone for exploring reactions, processes, and materials under controlled high pressure conditions. These versatile instruments enable researchers to simulate and study reactions that occur in extreme environments, leading to groundbreaking insights and innovations across various scientific disciplines. This article delves into the concept of a high pressure lab reactor, its applications, and the benefits it brings to the realm of scientific exploration and technological advancement.

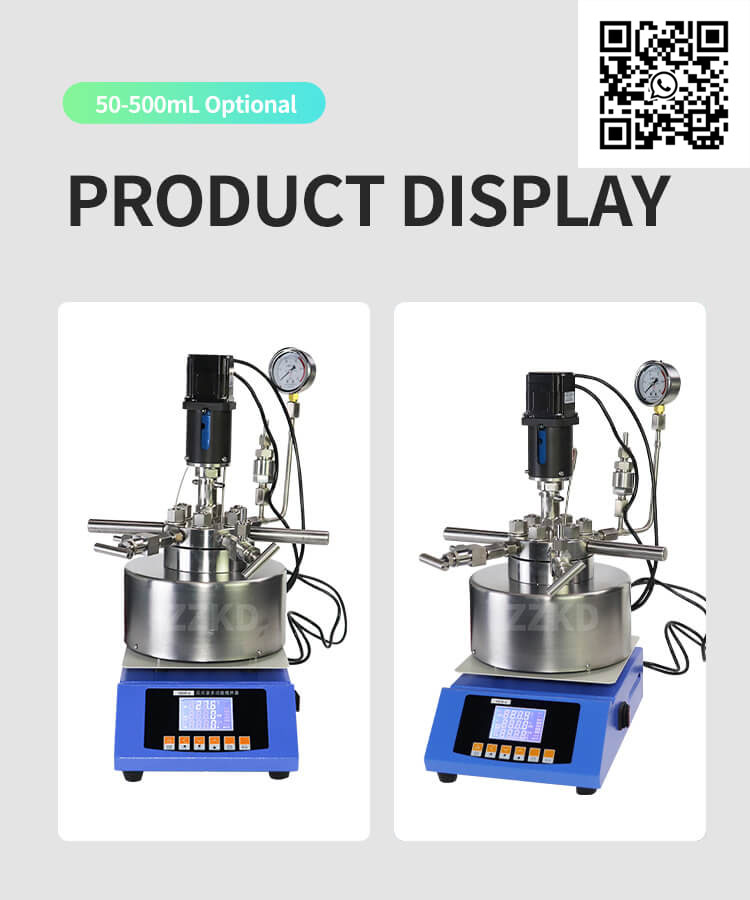

Understanding High Pressure Lab Reactors

A high pressure lab reactor is a specialized apparatus designed to create and maintain controlled high pressure environments for various chemical, biological, and material science experiments. These reactors are equipped with features that allow scientists to manipulate and monitor reaction conditions, such as temperature, pressure, and reactant concentrations. The key differentiator of high pressure reactors is their ability to maintain pressures significantly above atmospheric pressure, often in the range of 1000 to 5000 psi. This elevated pressure environment can lead to distinct reaction pathways, increased reaction rates, and the formation of novel compounds that may not be attainable under normal conditions.

Applications Across Scientific Disciplines

1. Catalysis and Chemical Reactions

High pressure lab reactors play a pivotal role in catalysis studies, where researchers investigate how different catalysts influence chemical reactions under high pressure conditions. For instance, the study of Fischer-Tropsch synthesis, a vital process in the production of synthetic fuels, benefits from high pressure conditions that enhance catalyst efficiency and selectivity. Moreover, the application of high pressure in catalysis research allows scientists to tailor reaction pathways, optimize yields, and improve energy efficiency in chemical manufacturing.

2. Polymerization and Material Synthesis

The field of polymer chemistry extensively employs high pressure lab reactors for polymerization reactions. For instance, the synthesis of high-density polyethylene (HDPE) necessitates high pressure conditions to produce polymers with controlled molecular weights and desirable properties. Furthermore, supercritical CO2-assisted polymerization has gained traction as a sustainable method to create unique polymer architectures, underscoring the versatility of high pressure lab reactors in designing novel materials.

3. Pharmaceutical Research and Drug Development

High pressure reactors find their way into pharmaceutical research, specifically in the development of drugs and pharmaceutical intermediates. For example, drug crystallization processes can be significantly altered under high pressure conditions, leading to improved solubility and bioavailability. Moreover, the application of high pressure lab reactors in pharmaceutical research aids in exploring new crystalline forms of drugs, enabling enhanced drug delivery mechanisms.

4. Biomass Conversion and Biofuel Production

High pressure lab reactors contribute substantially to the field of biomass conversion, where organic materials are transformed into biofuels and value-added chemicals. In addition, enzymatic reactions for cellulose hydrolysis exhibit enhanced yields when conducted under high pressure conditions. Conversely, the depolymerization of lignocellulosic biomass to biofuels benefits from high pressure reactions that facilitate the breakdown of complex structures, thus reducing the overall reaction time.

5. Environmental Applications

High pressure lab reactors also find relevance in addressing environmental challenges. For example, carbon capture and storage (CCS) technologies aim to mitigate greenhouse gas emissions from industrial processes. High pressure reactions can aid in the formation of stable carbonate minerals from captured CO2, preventing its release into the atmosphere. Nevertheless, the implementation of high pressure CCS processes requires careful consideration of energy consumption and economic viability.

Advantages of High Pressure Lab Reactors

High pressure lab reactors offer several distinct advantages:

1. Controlled Reaction Conditions

High pressure conditions enable scientists to control reaction parameters more effectively, leading to reproducible results. As a result, researchers can study the influence of pressure on reaction pathways and gain deeper insights into complex reaction mechanisms.

2. Enhanced Reaction Rates

The use of high pressure lab reactors often leads to increased reaction rates, allowing researchers to achieve higher yields in shorter timeframes. This acceleration of reactions can be crucial for applications requiring rapid product formation.

3. Novel Compound Synthesis

High pressure environments facilitate the synthesis of unique compounds that may possess enhanced properties or functionalities. Similarly, the controlled pressure conditions can induce structural changes in molecules, yielding new compounds that might not form under standard conditions.

4. Green and Sustainable Processes

Some reactions performed under high pressure conditions require milder temperatures, reducing energy consumption and promoting environmentally friendly practices.

5. Technological Innovation

High pressure lab reactors drive technological innovation by enabling researchers to explore new frontiers in chemical and material science. As technology advances, high pressure reactors are likely to become more sophisticated, offering enhanced control, automation, and real-time monitoring capabilities.

Case: High Pressure Lab Reactor in Supercritical Fluid Extraction

As an application case study, consider the use of a high pressure lab reactor in the field of supercritical fluid extraction (SFE). This technique utilizes high pressure conditions to manipulate a substance's solubility and extract target compounds from solid matrices. In this case, a researcher aims to extract essential oils from plant materials for use in cosmetics and aromatherapy products.

By employing a high pressure lab reactor, the researcher can subject the plant material to supercritical CO2 conditions. This transforms CO2 into a supercritical fluid, displaying properties of both liquids and gases. Under these conditions, CO2 can effectively penetrate the plant material, dissolving and extracting essential oils without leaving behind solvent residues. The use of high pressure not only enhances the solubility of the oils but also allows for the selective extraction of desired compounds.

Conclusion

The high pressure lab reactor stands as a remarkable tool in the arsenal of modern scientific exploration. Its ability to replicate extreme conditions and generate unique reaction outcomes empowers researchers across diverse fields, from catalysis and material science to pharmaceuticals and environmental studies. With advancements in technology, high pressure lab reactors are poised to revolutionize our understanding of chemical and material processes, leading to innovative solutions and a deeper comprehension of the natural world. As scientists continue to harness the potential of high pressure environments, the boundaries of scientific knowledge are certain to expand, unlocking opportunities that were previously deemed inaccessible.