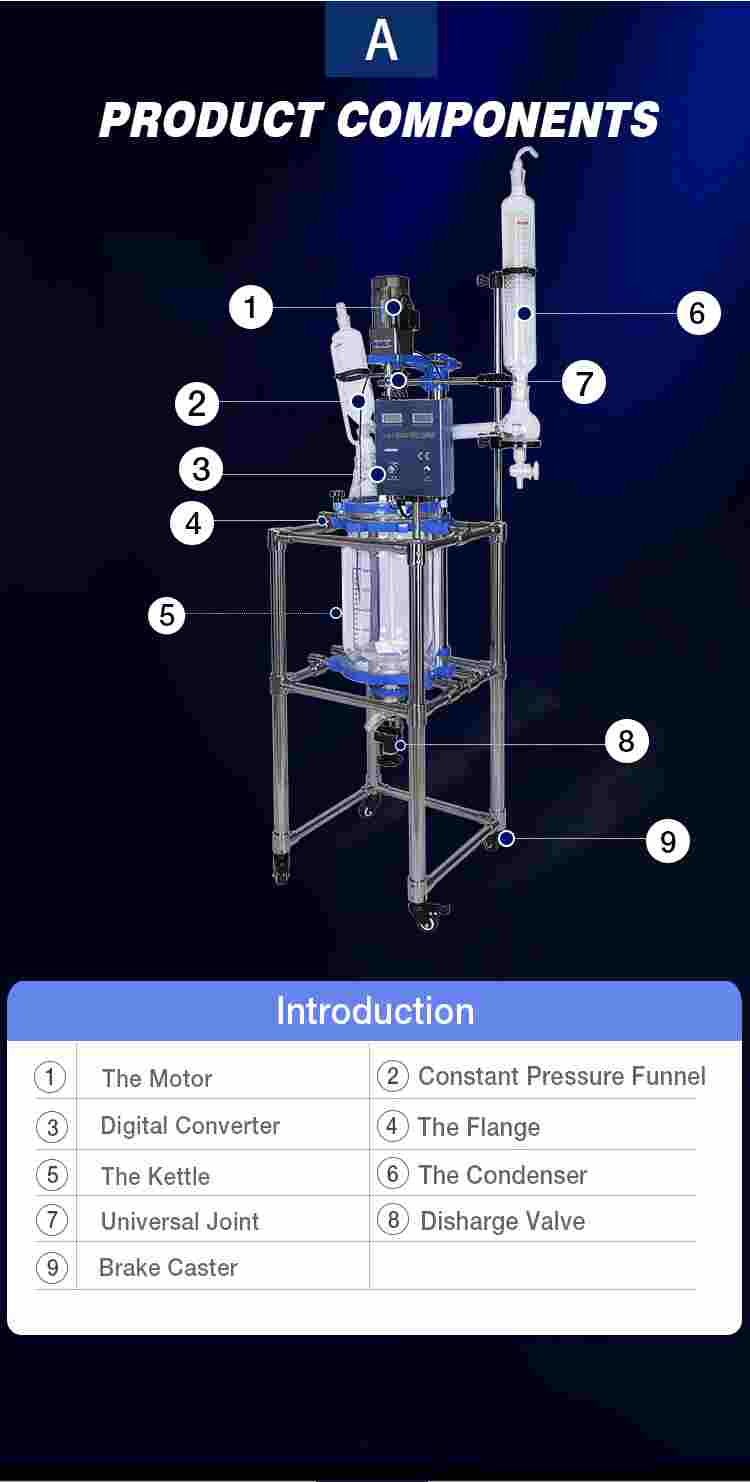

Glass reactor installation

The glass reactor is a double-layer glass design. The reaction solvent can be put into the inner layer for stirring reaction, and the interlayer can be passed through different cold and heat sources (refrigerated liquid, hot water or hot oil) for cyclic heating or cooling reactions. Under the set constant temperature condition, in a closed glass reactor, the stirring reaction can be carried out under normal pressure or negative pressure according to the requirements of use, and it can be used for the reflux and distillation of the reaction solution. It is a modern fine chemical factory, biological pharmacy and Ideal pilot and production equipment for synthesis of new materials. Installation of glass reactor:

Installation of glass reactor:

1. Before installing the equipment, check whether all parts are complete, and replace them if they are defective. During the installation process, crowbars, hand hammers, etc. should be rigorously contacted and collided with the glass parts to avoid damage to the glass lining. During the hoisting process of the reactor equipment, only supports and rings are stressed. Weak parts such as pipes, clamps, and nozzles are not allowed to be stressed. They must be lifted gently to avoid collisions, and do not hammer the tank. The glass surface of the equipment should be cleaned with water before installation.

2. The fastening of the reactor equipment flange and the connecting part should follow the chemical container installation principle, and it should be symmetrically and evenly tightened gradually to avoid damage to the glass surface due to excessive local force. In the process of disassembly, if you find that the gasket loses its elasticity, you should immediately replace it with a new one. The buckle of the reactor equipment is the main pressure component. In addition to the uniform force of the reactor during the installation process, the quality and quantity should be guaranteed, and it must not be installed with residues or reduced quantities. The sight glass mounted on the glass reactor is a brittle material. In addition to ensuring uniform tightening during installation, the pressing force should not be too large. If a local leakage occurs, the offset pad should be plugged immediately to avoid local excessive force and fragmentation. When installing the glass reactor agitator, attention should be paid to assembling anti-falling parts, and check whether the rotation direction of the agitator is consistent with the direction shown in the figure, so as to prevent the agitator from reversing and falling off during operation and damaging the lining.

3. If metal components are installed on the glass reactor, only welding on the outer surface of non-glass parts such as jackets is allowed. The welding speed should be fast and corresponding cooling measures should be taken. If welding should be done near the nozzle, inlet, and flange. Cover each nozzle tightly to avoid welding slag splashing and damaging the glass surface. After the equipment is installed on the glass reactor, various parts and the inside of the tank should be carefully inspected, and the empty test can be carried out after confirming that they are correct.

4. According to the height of use, fix the round bracket of the kettle on the vertical slider, and place the kettle body on the bracket. The semicircular hoops are used to fix the neck of the kettle and insert the vertical slider respectively. After closing, tighten the fixing screws. , When installing, pay attention to the vertical body of the reactor.

5. The stirring rod is fixed on the gear ring chuck of the motor spindle, the stirring rod passes through the rotating bearing in the middle of the cover, tighten the connector, and then adjust the position of the motor, paying attention to the vertical concentricity.

6. The slider on the pole is a stainless steel multi-purpose clamp that can be fixed and adjusted in different directions and heights.

7. On the left side of the bottle cap, the 34# standard port is inserted into the serpentine reflux condenser, the right 24# standard port is the feeding port, the middle front 19# standard port is the thermometer casing port, the bottom is equipped with a discharge valve, and the bottom of the kettle is separately It is the import and export of circulating fluid.

8. When installing the glass instrument, it must be cleaned, and each interface should be wiped with alcohol, and then coated with vacuum grease to prevent leakage.

9. Press the four pulley fixing device.

10. The air extraction port on the vacuum gauge is connected with the vacuum tube on the condenser, and the other air extraction port is connected to a vacuum pump or vacuum system.