Advantages of stainless steel chemical reactor and working principle

Our stainless steel reactors are available in 50L, 60L, 80L, 100L, etc. His supporting equipment includes SHZ-C circulating water vacuum pump, DLSB low temperature coolant circulation pump, GYY circulating water (oil) bath, GDX high and low temperature integrated machine Wait.

Advantages of stainless steel reactor:

1. The complete set of equipment accessories of stainless steel reactor have excellent mechanical properties, can withstand higher working pressure, and can also withstand the impact of massive solid materials when feeding.

2. Good heat resistance, wide operating temperature range (-196~600℃). It will not oxidize and peel at higher temperatures, so it can also be used for direct fire heating.

3. It has good corrosion resistance and no rust.

4. The heat transfer effect is better than that of the enamel reactor, and the heating and cooling speed is faster.

5. It has good processing performance, and can be made into stainless steel reactors of various shapes and structures according to technological requirements. 6. The wall of the kettle can be polished to make it free of material and easy to clean.

Application of stainless steel reactor:

The stainless steel reactor has the characteristics of rapid heating, high temperature resistance, corrosion resistance, sanitation, no environmental pollution, automatic heating without boiler, and convenient use. It is widely used in petroleum, chemical, rubber, pesticide, dye, medicine, food, and The completion of processes such as vulcanization, nitrification, hydrogenation, polymerization, condensation, etc., is based on the full mixing of the reacting substances. For the physical changes such as heating, cooling, liquid extraction and gas absorption, a stirring device is required to obtain To achieve good results, the outer coil reactor can be designed and processed for customers.

Principle of stainless steel reactor:

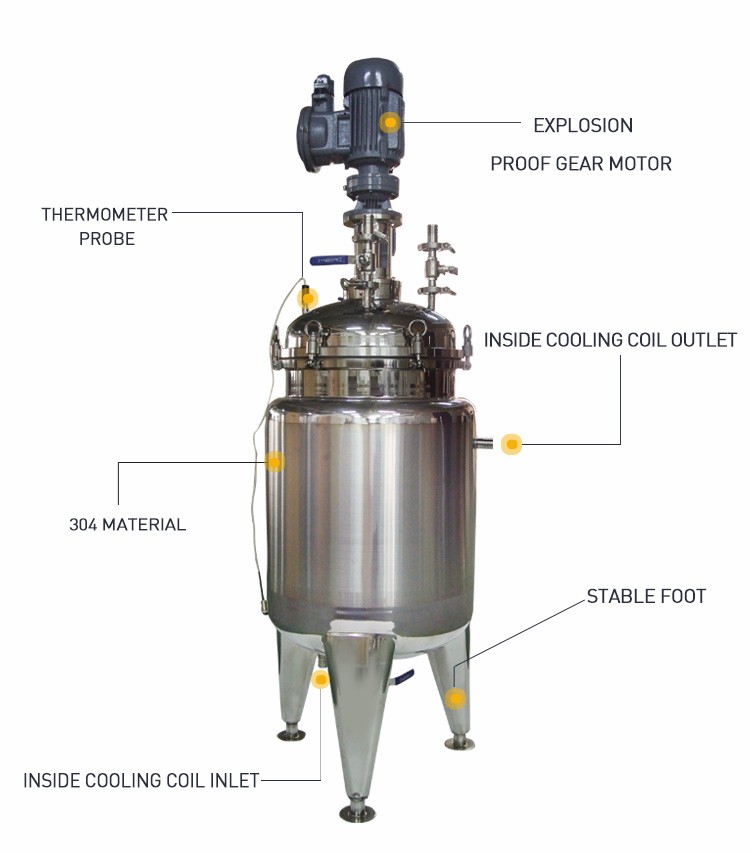

The structural principle and characteristics of the reactor: The reactor is composed of a pot body, a pot cover, a stirrer, a jacket, a support and transmission device, and a shaft sealing device. The material and opening can be made according to the user's process requirements. Heating forms include electric heating, oil heating, air heating, water heating (or cooling), and open flame heating. The jacket type is divided into: jacket type and outer half pipe type, and the jacket oil heating type is equipped with diversion device. The stirring forms generally include paddle type, anchor type, frame type, ribbon type, and wall scraping type. High-speed types include dispersed impeller type, turbine type, high shear type, propeller type, for customers to choose according to the process. Transmission forms include ordinary motors, explosion-proof motors, electromagnetic speed-regulating motors, frequency converters, etc., and reducers include cycloid pinwheel, worm gear, and planetary infinitely variable speed. The shaft seal is a common water-cooled packing seal, a combined PTFE packing seal, and a mechanical seal. The discharging forms include ball valve and down valve.

Application range of stainless steel reactor:

Stainless steel reactors are widely used in pressure vessels in chemical, food, coating, hot melt adhesive, silica gel, paint, medicine, petrochemical production, evaporation, synthesis, polymerization, saponification, sulfonation, chlorination, nitration, etc. , Such as reactor, reaction kettle, decomposition pot, polymerization kettle, etc. The reaction kettle is mainly composed of four parts: inner tank, jacket, stirring device, and support base (the structure with heat preservation can be adopted according to process requirements).