- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

Advantage:

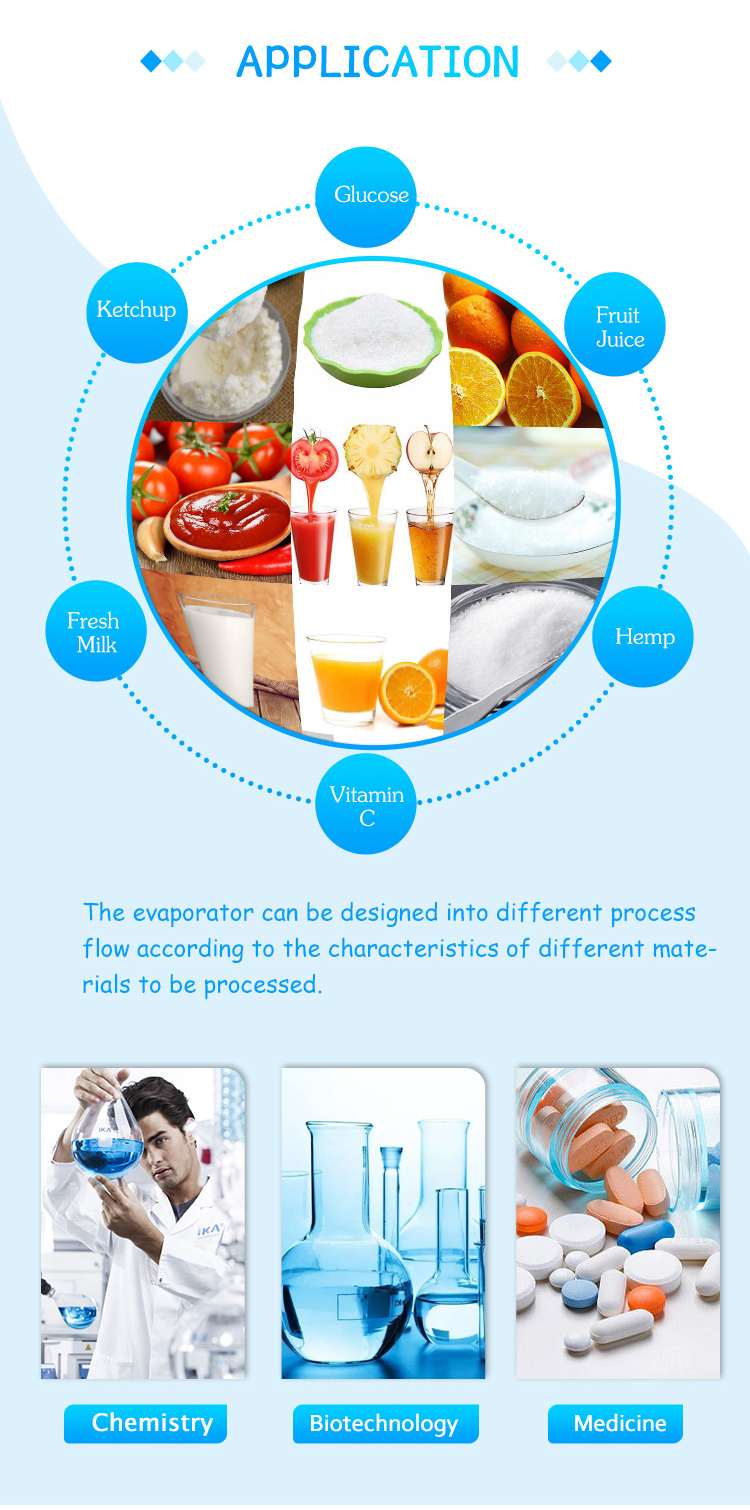

The falling film evaporator can operate continuously under vacuum and low temperature conditions, with large evaporation capacity, energy saving and consumption reduction, low operating cost, and can maintain the original composition of the processed material to the maximum. It is widely used in food, medicine, food deep processing, beverage, light industry, environmental protection, chemical industry and many other industries.

Features:

1. The special design can realize the switching effect after simple operation to adapt to the production of different products.

2. Large concentration ratio, falling film evaporation, make the material liquid with higher viscosity easy to flow and evaporate, and the concentration time is short.

3. The heating system is steam heating. The heating is uniform, the material liquid is liquid film flow evaporation, and it has the characteristics of high heat transfer efficiency and short heating time.

4. Continuous feeding and discharging, the required concentration of the material liquid can be achieved by one pass through the equipment.

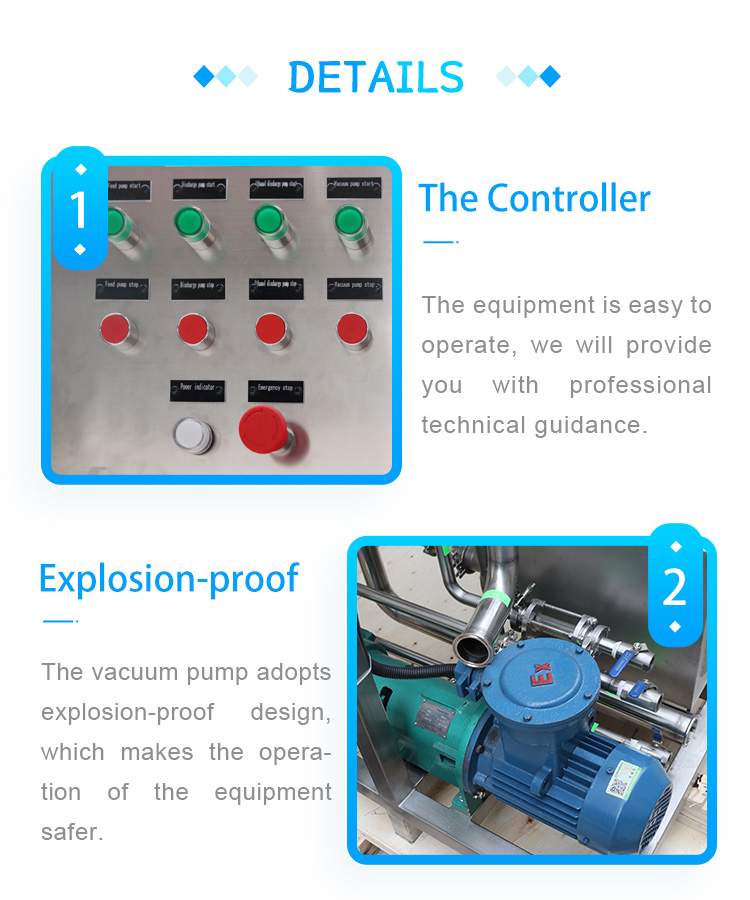

5. The equipment can be equipped with cleaning pipelines, which can realize on-site cleaning. The whole set of equipment is easy to operate and has no dead ends.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

1. What are the components of the falling film evaporator?

By each effect heating evaporator, each effect separator, condenser, heat pump, sterilizer, insulation pipe, vacuum system, each effect material liquid transfer pump, condensate drainage pump, operation platform, electrical instrument control cabinet and valves, pipes Road and other systems.

2. What are the application ranges of falling film evaporators?

It is widely used in the concentration of aqueous solutions such as glucose, starch sugar, oligosaccharides, maltose, sorbitol, fresh milk, fruit juice, vitamin C, and maltodextrin. It can also be widely used in waste liquid treatment in industries such as monosodium glutamate, alcohol and fish meal. The falling film evaporator performs continuous operation under vacuum and low temperature conditions, and has high evaporation capacity, energy saving and consumption reduction, low operating cost, and can maintain the original color, fragrance, taste and other components of the processed material. It has been widely used in many industries such as food, medicine, grain deep processing, beverage, light industry, environmental protection, chemical industry and so on.

3. How about the energy saving effect of falling film evaporator?

The energy-saving effect is significant, saving about 70% of the amount of steam than a single-effect evaporator.

Falling Film Evaporator | |

Treatment medium | CBD ethanol extract |

Design recovery capacity | 200L/h (alcohol) |

System heating source | Heated with saturated steam |

System cooling source | Using chilled water unit for circulating cooling |

System working power | 380V three-phase power, total installed power 10.15kw (380V,5O-60Hz) |

Equipment dimensions | 2.0 X2.0 X2.3 m |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap