- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

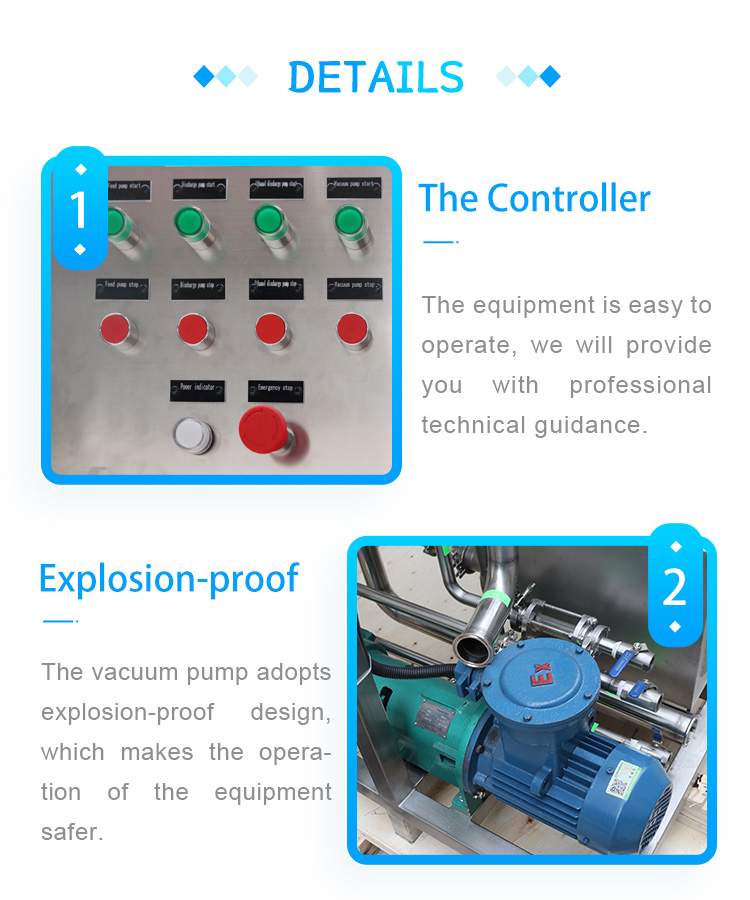

Advantage:

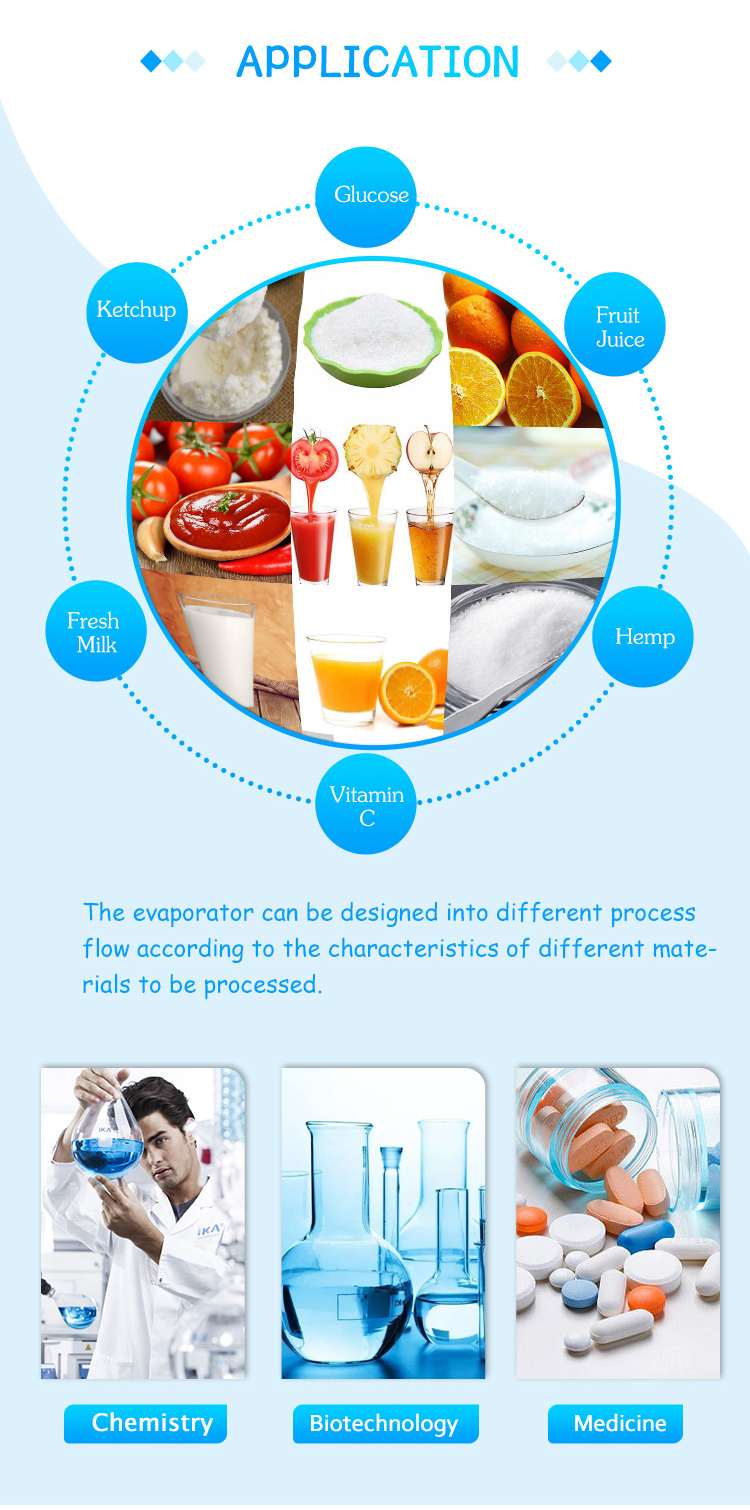

The falling film evaporator is operated in a vacuum state, the material evaporates at low temperature, and the heating time is short, which can keep the original flavor of the material to the maximum. Continuous in and out of materials, easy to operate, maintain and clean, widely used in food, pharmaceutical, chemical, environmental protection and other fields.

Features:

1. For the evaporation and concentration of food, the equipment can have sterilization function at the same time. The two processes of sterilization and concentration are completed at one time. The heating time of the material is short, which is suitable for the concentration of heat-sensitive liquid.

2. Since the process fluid flows only by gravity and is not driven by the high temperature difference, low temperature difference evaporation can be used.

3. The equipment can be equipped with an automation system to realize automatic control of the feed volume, automatic control of heating temperature, automatic control of the discharge concentration, and automatic control of cleaning.

4. It can be equipped with protective measures for sensitive materials in case of sudden power outages and failures. Other automatic operation and control of security and alarm.

5. The complete system has reasonable and beautiful design, stable operation, high efficiency and energy saving, and low steam consumption.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

1. What is the working principle of the falling film evaporator?

The material liquid is added from the top of the heating chamber and distributed by the liquid distributor. It flows downward in a film shape under the action of gravity, vacuum induction and air flow, and is heated and vaporized in the tube. The vaporized vapor and liquid are led out from the lower end of the heating tube. After the vapor-liquid separation, the concentrated liquid is obtained. The secondary vapor evaporated from the material liquid enters the next-effect evaporator for heating or enters the condenser.

2. Is the falling film evaporator suitable for food evaporation and concentration?

very suitable. For the evaporation and concentration of food, the equipment can have the sterilization function at the same time. The two processes of sterilization and concentration are completed at one time. The heating time of the material is short, which is suitable for the concentration of heat-sensitive liquid material;

3. What is the material used to make the falling film evaporator?

All parts in contact with materials are made of imported stainless steel and polished. The equipment has good corrosion resistance and is more convenient to clean. It is more in line with the requirements of pharmaceutical and food hygiene regulations. It can be equipped with a microcomputer control system, which is easier to use and more stable.

Falling Film Evaporator | |

Treatment medium | CBD ethanol extract |

Design recovery capacity | 200L/h (alcohol) |

System heating source | Heated with saturated steam |

System cooling source | Using chilled water unit for circulating cooling |

System working power | 380V three-phase power, total installed power 10.15kw (380V,5O-60Hz) |

Equipment dimensions | 2.0 X2.0 X2.3 m |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap