- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

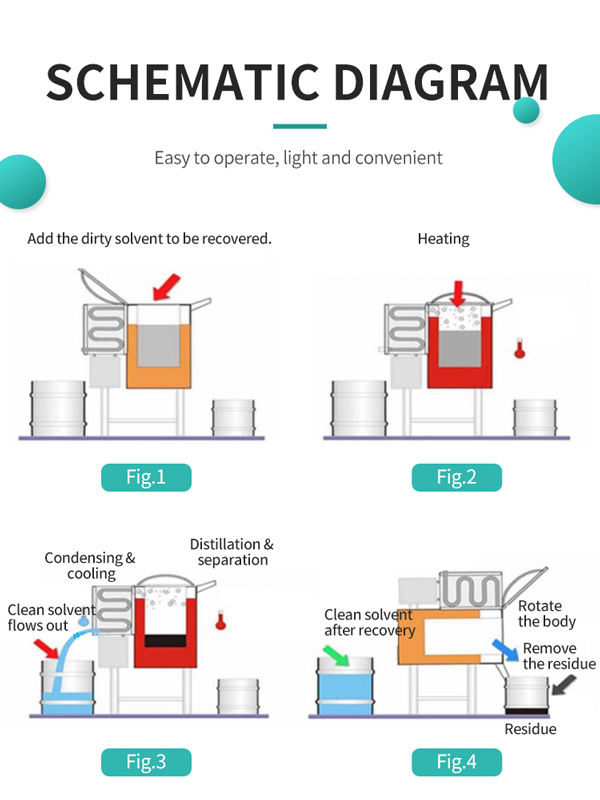

Solvent recovery machine is also called solvent regeneration equipment. Through the principle of distillation, the dirty solvent in the factory can be turned into a clean new solvent, and the distilled solvent can be put into production again, and the cleaning ability is not inferior.

Using the principle of distillation, the used waste solvents (such as Tanner water, banana water, thinner, boiling oil water, white electric oil, decontamination oil, plate washing water, net washing water, cleaning liquid, various cleaning agents, etc.) The high-purity liquid solvent is obtained after distillation, purification and concentration by the solvent recovery machine. The recovered solvent can be put into the production process again to realize multiple recycling and reuse of the solvent, which not only saves cost, but also protects the environment, killing two birds with one stone.

1. High safety. The whole machine and components adopt explosion-proof design and normal pressure structure. The connecting pipeline is sealed, and the solvent is not easy to spread and leak, and there is no potential safety hazard.

2. It is suitable for the recovery of most organic solvents, and the recovery rate is as high as 96%, which is beneficial to reduce production costs;

3. The electric control box is 100% sealed to prevent electric sparks from contacting with solvents;

4. Independent sealing design, the sealing ring of this machine is an integrated sealing ring produced by independent mold opening to ensure that solvent gas and solvent will not leak out and cause danger;

5. The heating temperature is controlled by a precise microcomputer program controller. The heating method adopts explosion-proof heating tube and indirect heating with hot kerosene. The distillation temperature is set according to the boiling point of different waste solvents, and multiple solvents can be separated and purified at the same time, saving electricity. , and has automatic control function;

6. The machine adopts automatic control, and the operation is simple and convenient.

7. With over-temperature protection and over-voltage protection;

8. The cooling principle of water-cooled heat exchange improves the speed and shortens the recovery time. The recovery speed is 1.5-2 times that of traditional air-cooled products. The high boiling point solvent can be recovered without a vacuum decompression device, and a slag discharge port is provided. The treated residue is easy to discharge for disposal, which is more convenient and safer than dumping the residue.

9. The equipment is all made of 304 stainless steel, which is resistant to corrosion by various solvents, and has a reasonable structural design. It has the advantages of fast heat transfer, less loss, small footprint, and convenient movement;

10. Low cost of use: as long as a small amount of water, electricity, and labor are needed, the operation is simple, and no professional and technical personnel are required to operate, and the work can be done according to the steps;

11. High efficiency: This equipment is low in price, high in efficiency and high in use value. The general factory can recover the investment cost within 3-6 months.

1. Operate correctly according to the instruction manual or professional training.

2. When adding solvent, clean the bottom of the pot, or clean it once a day; when changing the solvent, it must be cleaned, so as to avoid the reaction of solvents with different properties, which will affect the subsequent cleaning effect.

3. When the machine stops working, please turn off the power, if there is a vacuum pump, please turn off the air source.

4. Keep the equipment body clean and the site hygienic, and keep the solvent processing space ventilated.

The solvent recovery machine uses the principle of distillation to recover the used waste solvents (such as Tianna water, coking water, diluent, boiling oil water, white electric oil, decontamination oil, plate washing water, net washing water, cleaning liquid, various cleaning processes The solvent recovery machine distills, purifies, and condenses to obtain high-purity liquid solvents. The recovered solvents can be put into the production process again to realize multiple recovery and reuse of solvents, which not only saves costs but also protects the environment.

The appropriate solvent recovery machine manufacturer can be comprehensively selected from the aspects of solvent recovery machine brand, equipment material, equipment internal configuration, equipment operation flexibility, and after-sales service.

From the analysis of the social benefits of enterprises, the survival of enterprises is inseparable from the surrounding environment. The accumulation of a large amount of waste materials is bound to bring troubles to the surrounding environment and residents. If things go on like this, it will only make residents resent the company and affect the society where the company is located. picture. Enterprises should actively use solvent recovery machines to recycle waste solvents in factories, which not only saves solvent costs for enterprises, but also beautifies the surrounding environment and adds points to the social image of enterprises.

Model | Feed capacity (L) | Power supply (ACV) | Power (kW) | Temperature range (℃) | Treatment time (Min.) | Recovery (%) |

T-40Ex | 40 | 380 | 4 | 5~200 | 150 | 95 |

T-60Ex | 60 | 380 | 5 | 5~200 | 180 | 95 |

T-80Ex | 80 | 380 | 6 | 5~200 | 210 | 95 |

T-100Ex | 100 | 380 | 8 | 5~200 | 240 | 95 |

T-125Ex | 125 | 380 | 8 | 5~200 | 240 | 95 |

T-250Ex | 250 | 380 | 16 | 5~200 | 270 | 95 |

T-450Ex | 450 | 380 | 32 | 5~200 | 270 | 95 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap