Xylene Recycling Machine

The chemical industry is responsible for the production of countless goods that are essential to our modern way of life. However, the production of these goods often involves the use of hazardous chemicals, such as xylene, a common solvent used in the manufacturing of plastics, rubber, and other materials.

Solvent recovery machine that is harmful to human health and the environment. Exposure to xylene can cause respiratory problems, headaches, and nausea. In addition, xylene is a pollutant that can contaminate soil and water sources, leading to long-term environmental damage.

To address these issues, the development of xylene recycling machines has become increasingly popular in recent years. These machines are designed to capture and recycle xylene, reducing the amount of waste generated by the chemical industry while also mitigating the environmental impact of the production process.

How Xylene Recycling Machines Work

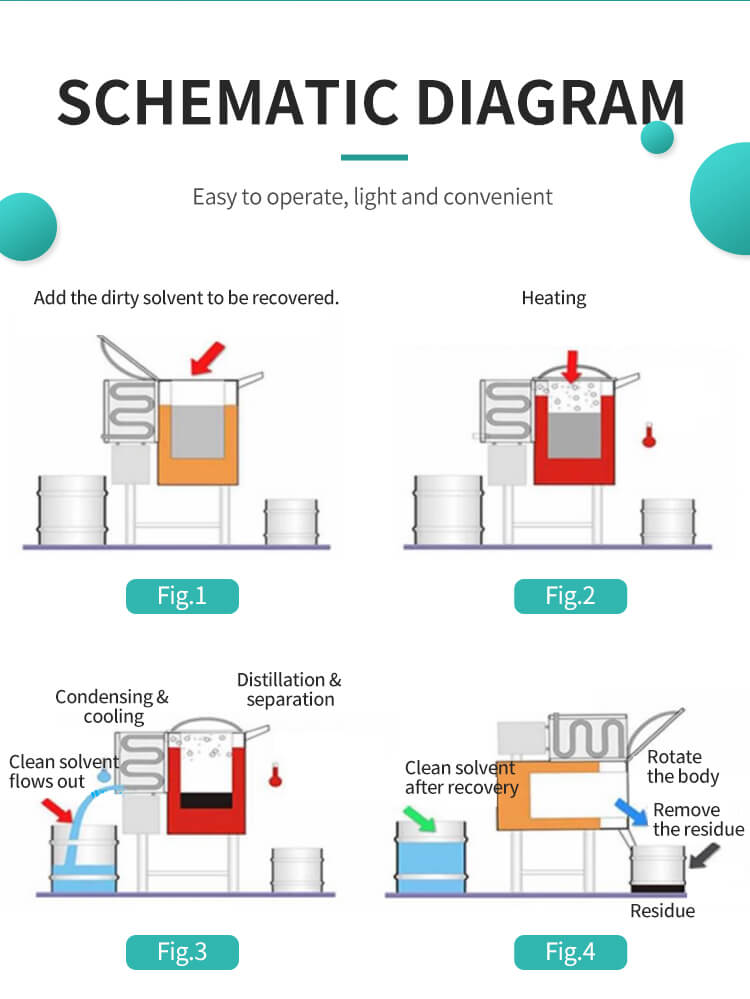

Xylene recycling machines use a variety of techniques to capture and purify xylene from waste streams. One common method is distillation, which involves heating the waste stream to vaporize the xylene. The resulting vapor is then condensed and collected for reuse.

Another method used in xylene recycling machines is adsorption, which involves passing the waste stream through a bed of adsorbent material that captures the xylene molecules. The adsorbent material can be regenerated and reused multiple times, making this method particularly efficient.

Xylene recycling machines can also utilize membrane filtration, which separates the xylene from other chemicals in the waste stream using a semi-permeable membrane. This method is particularly useful for separating small molecules like xylene from larger ones.

Benefits of Xylene Recycling Machines

Xylene recycling machines offer a range of benefits to the chemical industry, including:

Cost savings: By recycling xylene, companies can reduce the amount of waste they generate and minimize the need for expensive disposal methods. In addition, recycled xylene is often of higher quality than newly produced xylene, making it more valuable to the industry.

Environmental benefits: Xylene recycling machines help to reduce the amount of hazardous waste generated by the chemical industry, which in turn reduces the amount of pollution released into the environment. In addition, by recycling xylene, companies can reduce their carbon footprint and conserve natural resources.

Improved safety: Xylene is a hazardous chemical that can pose a risk to human health and safety. By capturing and recycling xylene, companies can minimize the risk of accidents and protect their workers from exposure to this dangerous compound.

Compliance: Many countries have regulations in place governing the use and disposal of hazardous chemicals like xylene. By using xylene recycling machines, companies can ensure that they are complying with these regulations and avoiding potential fines or legal issues.

Applications of Xylene Recycling Machines

Xylene recycling machines have a wide range of applications in the chemical industry. Some common uses include:

Solvent recovery: Xylene is commonly used as a solvent in the production of plastics, rubber, and other materials. By recycling xylene, companies can recover and reuse this valuable resource, reducing their reliance on newly produced xylene.

Waste reduction: Xylene recycling machines can be used to capture and recycle xylene from waste streams generated by chemical production processes. This reduces the amount of hazardous waste generated by the industry and minimizes the need for costly disposal methods.

Product quality improvement: Recycled xylene is often of higher quality than newly produced xylene, making it a valuable resource for the chemical industry. By using xylene recycling machines, companies can improve the quality of their products and reduce waste at the same time.

Xylene recycling machines offer a sustainable solution to the challenges faced by the chemical industry. By capturing and recycling xylene, companies can reduce their environmental impact, improve their bottom line, and ensure compliance with regulations governing hazardous chemicals. These machines offer a range of benefits, from cost savings to improved safety to product quality improvement, making them a valuable addition to any chemical production facility.

As the world becomes increasingly focused on sustainability and environmental responsibility, xylene recycling machines will likely become even more important in the chemical industry. By investing in these machines now, companies can position themselves as leaders in sustainable chemical production, while also minimizing their impact on the environment and protecting the health and safety of their workers.

Xylene recycling machines are a crucial technology in the chemical industry, offering a sustainable solution for the management of hazardous waste streams. By utilizing these machines, companies can reduce their environmental impact, improve their bottom line, and ensure compliance with regulations, while also improving the quality of their products and protecting their workers' health and safety. As the industry continues to evolve, xylene recycling machines will play an increasingly important role in shaping the future of sustainable chemical production.