Stainless Steel Reactor Vessel Specifications

Stainless steel reaction vessels refer to pressure vessels mainly used to complete physical and chemical reactions, such as reaction kettles, oxidation kettles, decomposition kettles, polymerization kettles, crystallization kettles, etc. Stainless steel reaction kettle is also called stainless steel reaction tank. It is composed of kettle body, kettle cover, agitator, heating and cooling jacket, support and transmission device, shaft sealing device, oil tank, etc. It is also equipped with electric heating rod, temperature measuring and pressure measuring gauge. Due to the different production processes and operating conditions of users, stainless steel reaction kettles generally have anchor type, paddle type, turbine type, propulsion type or frame type.

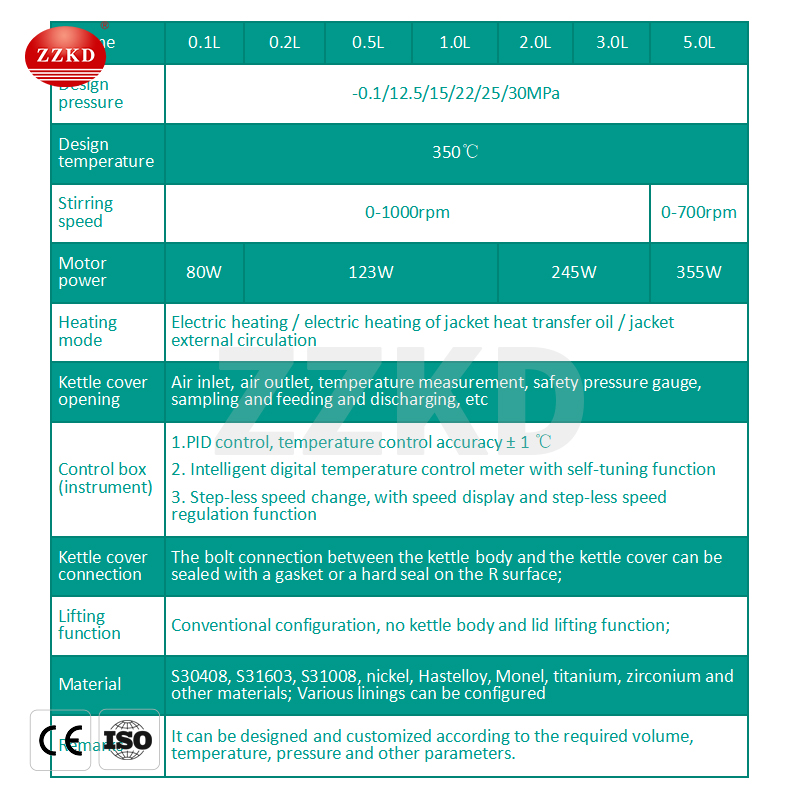

The outer wall of the jacket is welded with supports. The supports can be either suspended or supported. There is a discharge port on the first part of the pot body. Heat conduction oil is placed in the jacket of the electric heating stainless steel reaction kettle, which is heated by an electric heating rod. Oil discharge, overflow measurement, venting, electric heating rod, temperature measurement and other nozzle holes. The stainless steel reaction kettle heated by steam is directly charged with steam in the jacket for heating. The steam heating reaction kettle needs a stable supply of steam heat source, and a boiler is usually added. The heating methods include electricity, steam, heat transfer oil, infrared rays, etc.; the cooling methods are jacket, outer coil and inner coil cooling, and the speed of rotation is 0~1000r/min. The form of the stirring blade can be selected according to the user's requirements. Materials can be carbon steel, stainless steel, titanium, aluminum alloys, duplex steels and their composites.

In order to ensure that the reactor can operate well, the reactor must have sufficient strength, toughness, rigidity, good sealing performance and corrosion resistance. Reactors used in different processes can be made of suitable materials. In addition to the choice of reactor materials, accessories and the connection method of parts will also affect the safety of the reactor. The connection of the reactor accessories can be selected by welding or quick installation. Reasonable selection of accessories and connection methods is an effective measure to ensure the safe operation of the reactor. The safe use of the reactor must also consider the sealing and corrosiveness.

1. The reaction kettle often needs to be evacuated or work under a certain pressure, and the mechanical seal must be installed to meet the requirements; the stirring tank can be sealed with ordinary packing.

2. Observation medium mode: The reaction kettle observes the mixing of the materials in the kettle through the sight glass; the stirring tank is observed through the half-open cover or manhole of the upper flat cover, and the observation range is much larger than the sight glass of the reaction kettle.

3. Cost: The structure of the stirring tank is simpler than the reaction, which is directly reflected in the production cost, so the price of the reaction kettle of the same specifications is also higher than that of the stirring tank.

4. Heating device: The reaction kettle needs a heating jacket, or coil heating and cooling, that is, the stirring and mixing process of the medium is accompanied by the temperature to complete the reaction; and the stirring tank is usually only used as a simple stirring and mixing equipment, not participating in the reaction. The process of the reaction does not require heating.

5. Upper cover structure: the upper cover of the reaction kettle is a head; the upper cover of the stirring tank is usually a flat cover.

The advantages of stainless steel reactor:

1. The material can be stirred in a stainless steel reactor.

2. The sandwich structure can be used for heating or cooling of different cold and heat sources.

3. The material in the reactor is heated or cooled by injecting a constant temperature or cooling medium into the reactor sandwich. At the same time, it can lead to normal or negative pressure conditions.

The material is reacted in a stainless steel reactor, the reaction solution is evaporated and the flow is controlled.

4. After the reaction, the material is discharged from the outlet at the bottom of the kettle, and the operation is simple and convenient.

5. The stainless steel reactor equipment can be designed and customized according to the production process of the material to realize the technical configuration of heating, evaporation, cooling, low speed and high speed to better meet the production needs; better corrosion resistance makes it have a longer life. It has a long service life, saves production costs, and is suitable for enterprise use.

6. Stainless steel reactors are used in petrochemical, rubber, dye, pharmaceutical and other industries. This is a machine that reacts with two or more materials and uses mechanical force and gravity to complete the processes of sulfonation, nitration, hydrogenation, alkylation, polymerization, polycondensation, and many other organic dyes and their intermediates. Process reaction equipment.

Price and configuration of stainless steel reactor:

If the parameter configuration of the stainless steel reactor is different, then its price is also different. Generally, it is composed of pot cover, pot body, stirrer, etc. It is suitable for mixing, stirring, and so on. Generally, before using it, it is necessary to check some components of the reactor, such as pressure gauges, thermometers, etc., and also check whether there are leaks in the pipes, etc. When processing solid materials, care should be taken to avoid damage to the wall of the reactor.

The price of the reaction kettle in the current market is also different, so the price of the stainless steel reaction kettle is directly related to the configuration. The price of the stainless steel reaction kettle is mainly set according to the size、specifications and parameters of the reaction kettle. With the development of modern society, the position occupied by stainless steel reactors in the current society is becoming more and more important. Stainless steel reactors are also required in many fields. Among them, in chemical, petroleum and other fields, stainless steel reactors The kettle has become an indispensable component. Stainless steel reactors are widely used in petroleum, chemical, rubber, pesticides, dyes, medicine, food and other production users and research on various scientific research and experimental projects to complete hydrolysis, neutralization, crystallization, distillation, transpiration, storage, hydrogenation, Containers for technical processes such as alkylation, polymerization, condensation, heating and compounding, and constant temperature reaction.