SFE co2 extraction equipment system

SFE co2 extraction equipment by ZZKD laboratory equipment manufacturer is highly intelligent and multi-module. High intelligence will be reflected in the operation, which can make it easier for users to get started. Multi-module means that the module function unit of the equipment can be expanded at any time. Below we will briefly introduce the supercritical fluid technology supercritical extraction device.

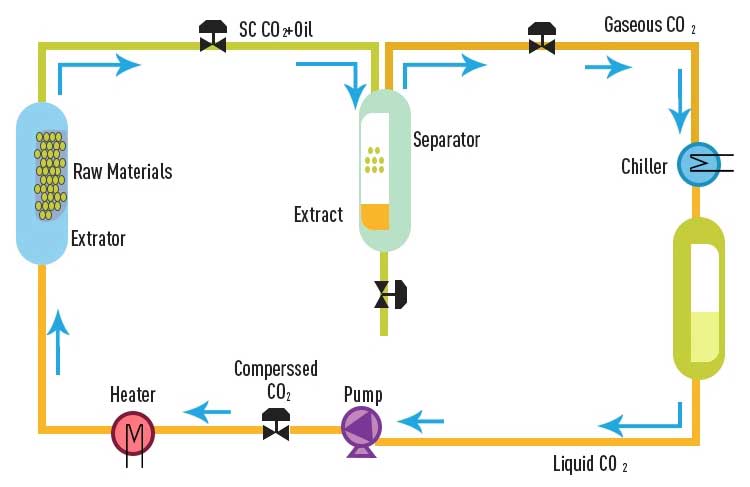

Principle of SFE co2 extraction equipment

Supercritical fluid extraction technology is currently the most advanced physical separation technology in the world.

In general supercritical fluids, CO2 has stable chemical properties, non-toxic, non-corrosive, non-flammable, non-explosive, easy to reach a critical state, and the critical temperature (31.1°C) is close to normal temperature. It is rich in aroma components, physiologically active substances, enzymes or proteins and other heat-sensitive substances that have no destructive effect. Therefore, in practical applications, CO2 is often used as the extraction medium for supercritical extraction.

Since the concentration of supercritical CO2 is very sensitive to temperature and pressure changes, adjusting the pressure or temperature of CO2 can adjust the concentration of CO2, so that the target extract is dissolved in the raw material.

In the supercritical extraction process, the extracts obtained in different pressure and temperature ranges are not single. Under these conditions, the best mixed component ratio can be obtained. Then, the supercritical fluid is converted into ordinary gas through decompression and temperature rise. The extract is completely or basically separated to achieve the purpose of separation and purification. This is a traditional method. Supercritical CO2 extraction process.

Structure of SFE co2 extraction equipment

The device is mainly composed of extraction kettle, separation kettle, rectification tower, C2 high pressure pump, carrier pump, refrigeration system, heat exchange system, purification system, extraction tank voltage stabilization system, C2 storage tank, flow meter, temperature and pressure control protection, Computer acquisition system and other components.

The main technical parameters

1. Extraction kettle: 05L, 1, 2L, 5L/50 Mpa, 10L, 24L/4 OMpa, 50-200 L/32 Mpa, dual-purpose solid and liquid. The water distribution jacket can be recycled and the temperature is adjustable.

2. Separating kettle: 03-10L/30Mpa, 50-200L/16-22Mpa. The water distribution jacket can be recycled and the temperature is adjustable.

3. The inner diameter of the distillation column is 125×2-3m/30 mpa, 135×2-3m/3 ompa, Φ48x4-6m/30 mpa, 178x4-6m30 mpa, which can also be divided into 4 sections, 6 sections, and 8 sections according to the process requirements. Temperature control; the user can choose the corresponding filler according to the process requirements.

4. CO2 high pressure pump: 20L/40 Mpa·h three plunger frequency modulation, 50L/50 Mpa·h three plunger frequency modulation, 400 L/40 Mpa·h three plunger frequency modulation, 800 L/40 Mpa·h three plunger frequency modulation Frequency modulation, pump head cooling system.

5. In the extraction process, the carrier pump is used for extraction to change the polarity of CO2 and expand the scope of application.

6. Refrigeration system: equipped with semi-hermetic compressor and hermetic compressor, the refrigeration capacity meets the technological requirements.

7. Heat exchange and temperature control system: According to the process requirements, the extraction kettle, separation kettle and rectification tower are equipped with heat exchange system and temperature control system respectively. Double screens control the temperature of the water bath, test the temperature of the CO2 fluid, and the temperature control accuracy is ±1℃.

8. Pressure control (protection): The outlet of the high-pressure pump is assigned a contact pressure gauge, the working pressure is set, and the overpressure protection automatically stops the pump. The high-pressure pump, extraction kettle, separation kettle, and distillation tower are all equipped with a maximum working pressure safety valve, and automatic pressure relief protection for overpressure. The outlet of the pumping kettle is equipped with a back pressure valve system. Ensure that the pressure is stable, easy to adjust, and the pressure control accuracy is ±0.1Mpa.

9. Flow display: metal rotor flowmeter, digital display remote transmission, respectively display instantaneous flow and cumulative flow

10. Piping: containers, valves, fittings and pipes in contact with fluid are made of stainless steel

11. Others: three-phase four-wire system 380 V/50 Hz, CO2 food grade ≥99.5%, user power supply.

SFE co2 extraction equipment application range

Used for university teaching, extraction of natural products, active ingredients of Chinese herbal medicine, edible oils and fats are beneficial to health, pesticide residues, heat-sensitive, biologically active ingredients, natural flavors, spices, low-boiling volatile ingredients, and separation and purification of chemical mixtures, etc. Field research, pilot test and industrial production.