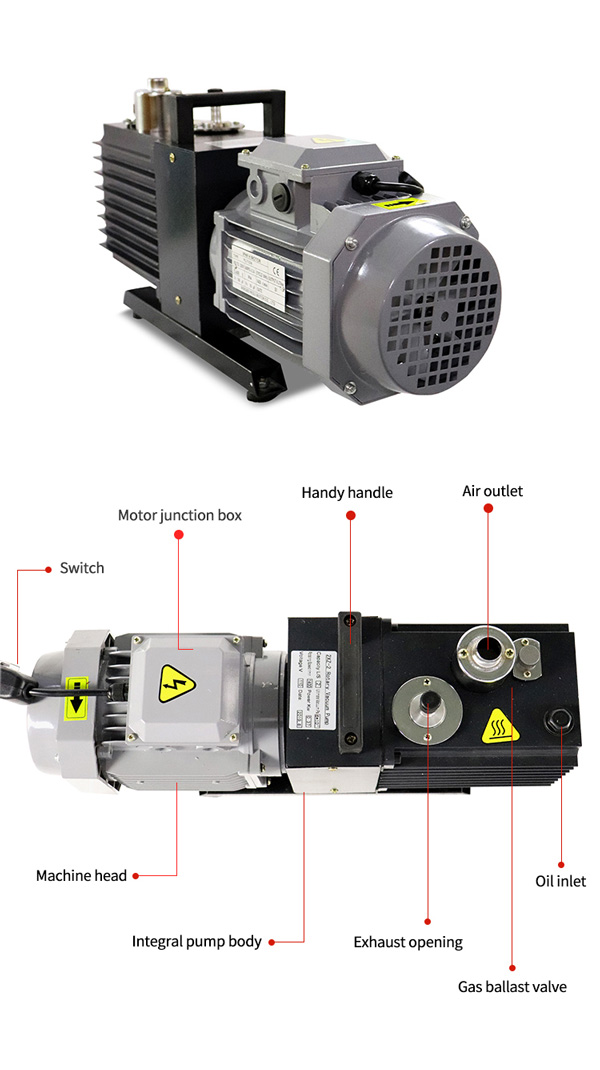

Dual Stage Rotary Vane Vacuum Pump

As one of the most basic vacuum acquisition equipment in vacuum technology, the dual stage rotary vane vacuum pump is mainly composed of pump body, rotor, rotary vane, end cover, spring and so on. The pump cavity is equipped with a rotor, and there are rotating vanes in the rotor groove. When the rotor drives the rotating vane to rotate, the rotating vane is close to the cavity wall to separate the intake and exhaust ports and to periodically expand the volume of the intake cavity to inhale and exhaust. The volume of the air cavity is periodically reduced to compress the gas, and push the exhaust valve to exhaust the gas to obtain a vacuum. The principle of the rotary vane vacuum pump means that its working performance is composed of two parts: high pressure stage and low pressure stage. The suction port is connected to the vacuum equipment, and a large amount of gas in the container is sucked and discharged during operation. When the equipment obtains vacuum, the high pressure stage exhausts. The valve is closed, and the gas at the inlet of the high-pressure stage will be transferred to the second stage, and a certain vacuum can be obtained through the second stage suction and discharge vacuum equipment.

Dual stage rotary vane vacuum pump scope of application:

1. The dual stage rotary vane vacuum pump is the basic equipment used to pump out the gas in a specific sealer to obtain a certain degree of vacuum for the container. Due to the high development of modern science and technology, the application of vacuum pumps has spread throughout various scientific fields and various enterprises. It can be used by research institutes, colleges and universities, industrial and mining enterprises in metallurgy, chemical industry, light industry, petroleum, medical treatment, pharmaceuticals, printing and dyeing, electrical appliances, electric vacuum, semiconductor, food, atomic energy, textiles, etc. for scientific research, production and teaching.

2. Since the vacuum pump is made of ferrous metal and is more precise, the work of the whole pump is connected with oil, so it is not suitable for pumping out the highly oxygenated, toxic and explosive corroded ferrous metal Various gases that have a chemical effect on vacuum oil cannot be used as compressors and delivery pumps. If there is a pump with gas ballast device, a certain amount of condensable gas can be pumped out.

3. The dual stage rotary vane vacuum pump can be used to directly obtain the vacuum operation with a vacuum degree below 10-3 Torr, and to obtain a vacuum function with a vacuum degree above 10-3 Torr with other vacuum equipment.

4. The dual stage rotary vane vacuum pump is generally used in an environment where the room temperature is not lower than 5°C and the relative temperature is not higher than 90%.

Dual stage rotary vane vacuum pump maintenance and maintenance:

1. Frequently check the oil quality, and replace the new oil in time if the oil is found to be deteriorated, so as to ensure the normal operation of the vacuum pump.

2. The oil change period is determined by the user according to the actual use conditions and whether the performance requirements can be met. Generally, when a new vacuum pump pumps out clean and dry gas, it is recommended to change the oil every 100 hours or so. After no black metal powder can be seen in the oil, the oil change period can be extended appropriately in the future.

3. Under normal circumstances, the vacuum pump should be overhauled after working for 2000 hours, check the aging degree of the rubber seal, check whether the exhaust valve is cracked, and clean up the dirt deposited on the valve and exhaust valve seat. Clean the parts in the entire vacuum pump cavity, such as rotors, rotary vanes, springs, etc. Generally, it is cleaned with gasoline and dried. After cleaning the rubber parts, wipe them dry with a dry cloth. When cleaning the assembly, handle it with care and be careful not to scratch it.

4. If possible, clean the pipe as well to ensure the smooth flow of the pipe.

5. After reassembly, a trial run should be carried out. Generally, it must be run dry for 2 hours and the oil should be changed twice. Because there will be a certain amount of volatile matter in the vacuum pump during cleaning, it will be put into normal work after it runs normally.

6. Unscrew the water diversion screw plug of the vacuum pump body, and pour water (or slurry).

7. Start the motor. When the vacuum pump is running normally, open the outlet pressure gauge and the inlet vacuum pump. After seeing the appropriate pressure, open the gate valve gradually, and check the load of the motor at the same time.

8. Try to control the flow rate and head of the vacuum pump within the range indicated on the label to ensure that the vacuum pump operates at the highest efficiency point to obtain the greatest energy-saving effect.

9. If abnormal noise is found in the dual stage rotary vane vacuum pump, stop the machine immediately and check the cause.

10. During the first month of operation, the lubricating oil should be replaced every 100 hours, and the oil should be changed every 500 hours thereafter.

11. Frequently adjust the packing gland to ensure that the dripping in the stuffing chamber is normal (preferably dripping out).

12. When the vacuum pump is used in the cold winter season, after parking, it is necessary to unscrew the drain plug at the lower part of the pump body to drain the medium. Prevent frost cracking.

13. If the dual stage rotary vane vacuum pump is out of service for a long time, it is necessary to disassemble the pump completely, wipe off the water, apply grease to the rotating parts and joints, install them, and keep them properly.