Professional Rotary Vane Vacuum Pump Supplier

Professional rotary vane vacuum pump is a device that uses mechanical, physical, chemical or physical chemical methods to generate, improve and maintain vacuum in a certain closed space. It is widely used in the fields of medicine, chemical industry, electronic technology, vacuum drying, refrigeration, etc. Rotary vane vacuum pumps are the most widely used as primary pumps. Zhengzhou Keda is a professional supplier of rotary vane vacuum pumps, specializing in the production of rotary vane vacuum pumps.

The principle of use of the rotary vane vacuum pump:

Professional rotary vane vacuum pumps consist of two working chambers. The front-stage pump is a low-vacuum stage, and the back-stage pump is a high-vacuum stage. The pumped gas enters the front stage through the latter stage, and is discharged out of the pump through the exhaust valve. The front and rear stages are slightly different: the pump chamber of the latter stage is larger than that of the previous stage, and the former stage is the same as the unipolar pump, and oil enters the pump chamber at any time, while the latter stage only has a small amount of oil when it starts to work, and it works for a period of time After that, no oil will enter the pump cavity. When the latter stage is working, part of the gas is directly discharged to the atmosphere from the rear exhaust valve, and part of the gas is discharged to the atmosphere through the front pump; after working for a period of time, the gas in the latter pump is compressed and the pressure cannot reach Above one atmospheric pressure, if the rear exhaust valve cannot be pushed open, these gases will be completely exhausted from the front stage. As the pumping time lasts for a long time, the pressure at the inlet of the back stage pump drops greatly, the outlet pressure of the professional rotary vane vacuum pump is also very small, the pressure difference between the inlet and outlet is also small, and the amount of compressed gas returned is reduced correspondingly. The oil molecules that are easy to evaporate in the backing pump are continuously sucked away by the backing pump, and the partial pressure of the oil vapor is thus reduced. This can improve the ultimate vacuum of the pump. The oil pollution is also smaller than that of a single-stage pump.

Professional rotary vane vacuum pump features:

1. Design features:

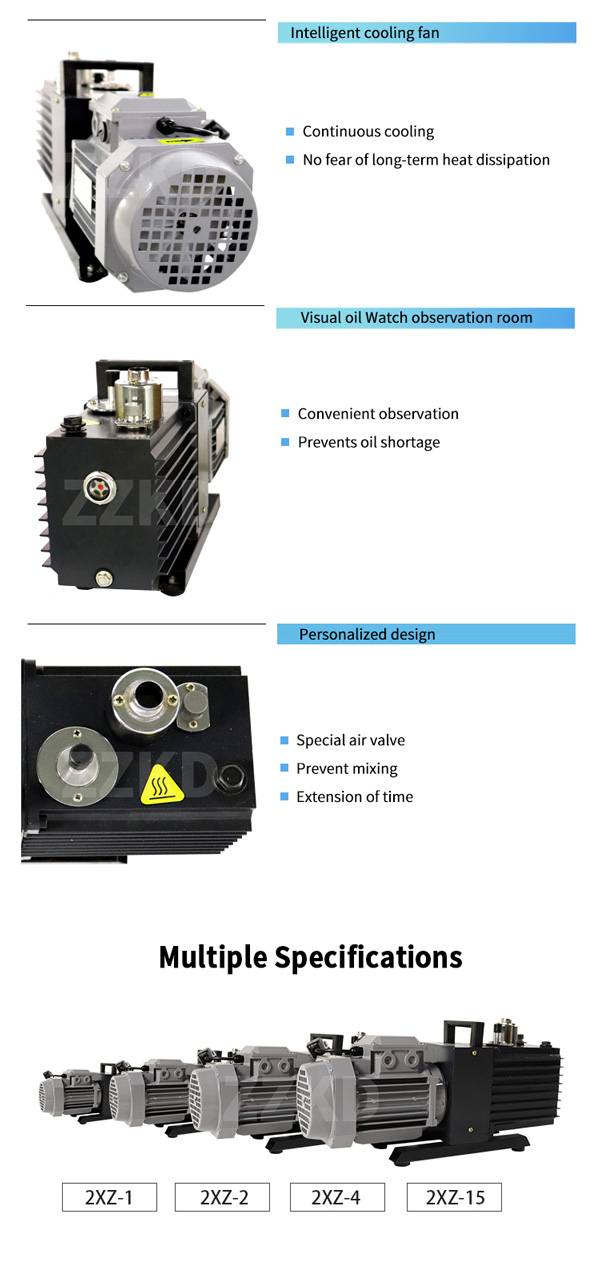

·The overall design of the rotary vane vacuum pump: The motor and the pump of the rotary vane pump adopt an integrated design, which makes the whole pump more compact and light.

·Professional rotary vane vacuum pump appearance design: The motor housing of the vacuum pump is made of aluminum alloy, which has high heat dissipation efficiency, ensures long-term continuous normal operation, and has a good appearance.

·The internal design of the rotary vane vacuum pump: the oil tank of the rotary vane pump is treated as a partition, and an oil-gas separation device is installed in the exhaust, so there is no oil injection and oil mist pollution is reduced.

·Oil return design of the rotary vane vacuum pump: In order to avoid the oil return of the vacuum pump, the rotary vane pump has a special design at the inlet port, which can prevent the pump oil from returning to pollute the evacuated device and pipeline after the pump is stopped.

2. Performance characteristics:

·Professional rotary vane vacuum pump can have higher pumping speed in a wider pressure range.

·The rotor of the rotary vane vacuum pump has good geometric symmetry, and the pump runs relatively smoothly during the working process.

·In the structural design of the rotary vane pump, there are gaps between the rotors and between the rotor and the housing, so the wear is small; at the same time, the driving power is reduced to achieve high-speed operation.

·Professional rotary vane vacuum pump does not need oil seal and lubrication in the pump chamber, which can reduce the pollution of oil vapor to the vacuum system.

3. Dynamic balance characteristics:

·Professional rotary vane vacuum pump impeller and pump body adopt shrink-fit interference fit, reliable performance and stable operation , can adapt to the harsh working conditions of load shock fluctuations. The single-stage single-acting structure has the advantages of simple structure, convenient maintenance, reliable operation, high efficiency and energy saving, and can adapt to harsh working conditions such as large displacement and load shock fluctuations. A series of optimized designs have been carried out on key components such as distribution plates, impellers and pump shafts, which simplifies the structure, improves performance and realizes energy saving. Ductile iron or welded impeller is adopted, and the blade is stamped and formed at one time, with reasonable profile; the hub is all processed, which fundamentally solves the problem of dynamic balance.