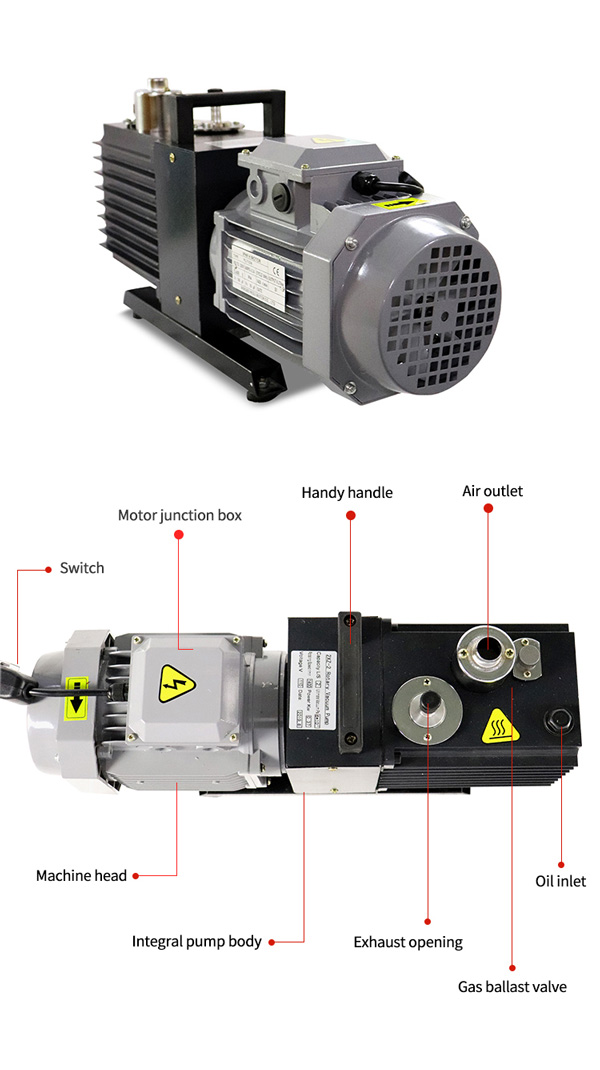

Dual Stage Rotary Vane Vacuum Pump

Dual stage rotary vane vacuum pump is generally used in conjunction with laboratory instruments such as rotary evaporators and glass reactors. Its main function is to vacuum.

How does a dual stage rotary vane vacuum pump work:

Dual stage rotary vane vacuum pump, which has two or more rotors mounted eccentrically in the stator cavity and rotor slot. The rotor is tangent to or intersects the inner surface of the pump casing. When the rotor drives the rotor to rotate, the rotor uses centrifugal force (and a certain spring force) to close the cylinder wall to separate the intake and exhaust ports, the container in the intake chamber periodically expands to suck in air, and the volume of the exhaust chamber decreases periodically to compress the gas. Use the pressure of gas and oil to push the exhaust valve to exhaust, so as to obtain vacuum.

Application range of dual stage rotary vane vacuum pump:

1. The dual stage rotary vane vacuum pump is the basic equipment used to pump out the gas in a specific sealer so that the container can obtain a certain degree of vacuum. Due to the high development of modern science and technology, the application of vacuum pumps has spread throughout various scientific fields and various enterprises. It can be used by research institutes, colleges and universities, industrial and mining enterprises in metallurgy, chemical industry, light industry, petroleum, medical treatment, pharmaceuticals, printing and dyeing, electrical appliances, electric vacuum, semiconductor, food, atomic energy, textiles, etc. for scientific research, production and teaching.

2. Since the dual stage rotary vane vacuum pump is made of ferrous metal and is relatively precise, the work of the entire pump is connected with oil, so it is not suitable for pumping out oxygen-rich, toxic, and explosive gases. Various gases that corrode ferrous metals and have chemical effects on vacuum oil cannot be used as compressors and delivery pumps. If there is a pump with gas ballast device, a certain amount of condensable gas can be pumped out.

3. The dual stage rotary vane vacuum pump can be used to directly obtain the vacuum operation with a vacuum degree below 10-3 Torr, and to cooperate with other vacuum equipment to obtain a vacuum effect with a vacuum degree above 10-3 Torr.

4. The dual stage rotary vane vacuum pump is generally used in an environment where the room temperature is not lower than 5°C and the relative temperature is not higher than 90%.

Maintenance of dual stage rotary vane vacuum pump:

1. First of all, we must understand the types, characteristics and current status of two-stage rotary vane vacuum pumps. Understand usage requirements and determine maintenance goals. Before making repairs, be prepared to inspect the method.

2. Judging and diagnosing faults. Accurate judgment can save trouble. Confirm the diagnosis.

3. Solve problems, first simple and then complex, first easy and then difficult. Do not disassemble what does not need to be disassembled. In order to reduce new damage caused by lack of special tools and improper operation, reduce transposition and running time. Generally speaking, the spliced rotor cannot be disassembled, otherwise the shape and position tolerance cannot be guaranteed, and the rotor will be scrapped.

4. For toxic, harmful and corrosive water pumps, users should be required to clean them first, and inform them of necessary protective measures to protect the health of maintenance personnel.

Precautions for dual stage rotary vane vacuum pump:

1. It can work continuously for a long time under the condition that the ambient temperature is within the range of 5-40°C and the inlet pressure is less than 1330Pa.

2. If it is equipped with a gas ballast device, it can also pump out a certain amount of condensable gas, but it is not suitable for pumping out high oxygen content, poisonous, explosive, corrosive to metal, and chemically harmful to pump oil. Reactive, as well as gases containing particulate dust, also cannot be used as transfer pumps.

3. The continuous working time under the inlet pressure of atmospheric pressure to 6000Pa shall not exceed 3 minutes, so as to avoid damage to the pump caused by oil injection or poor lubrication.

4. The oil level should be at the center of the oil mark. A high oil level will cause oil injection, and a low oil level will cause poor lubrication. It is conducive to complete replacement, and at the same time, the impurities in the pump chamber can be discharged as much as possible.