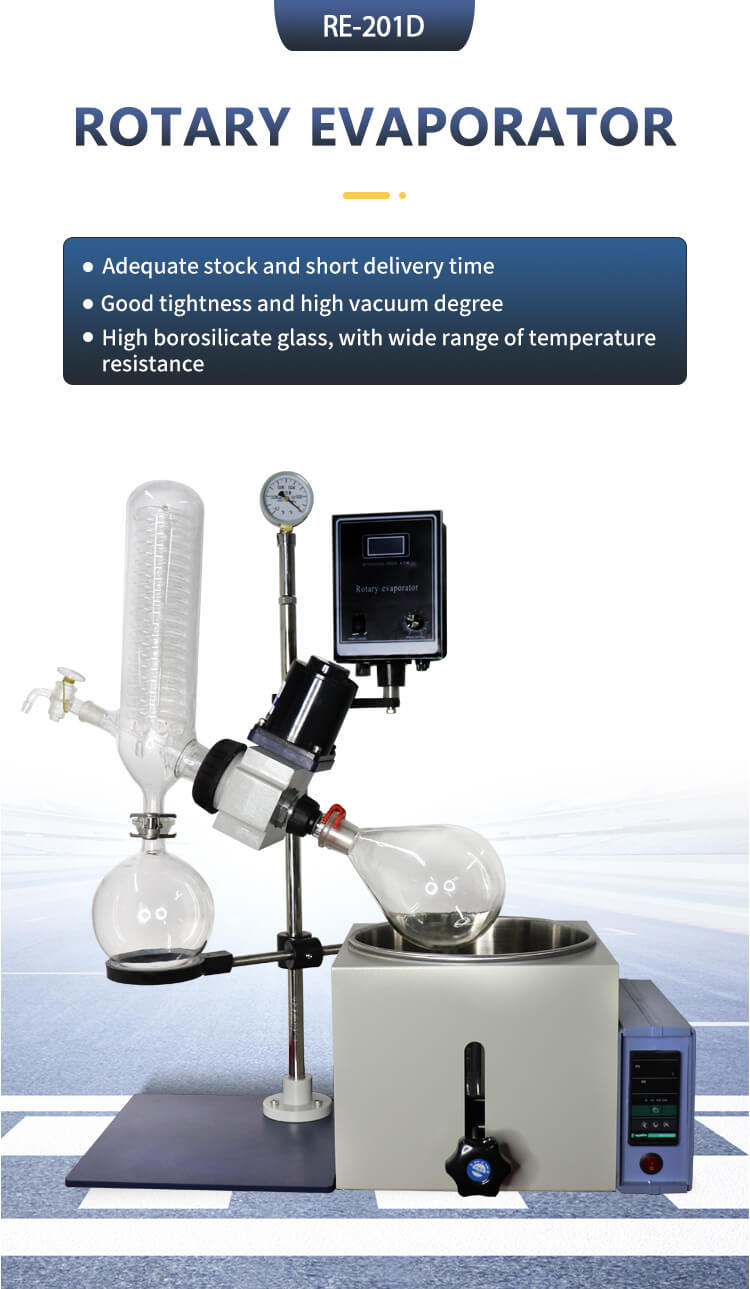

Lab Cbd Rotary Evaporator Distillation Instrument

What Is A Rotary Evaporator?

Rotating evaporator is usually used for concentration, drying, crystallization, separation, and solvent recovery within the pharmaceutical, chemical, and organic pharmaceutical industries. We should think about the following factors when buying a rotating evaporator. 5L rotovap for sale is the highest best and enormous rotary evaporating system useful in various industrial applications. The evaporator is utilized in distilling and separating chemical compounds.

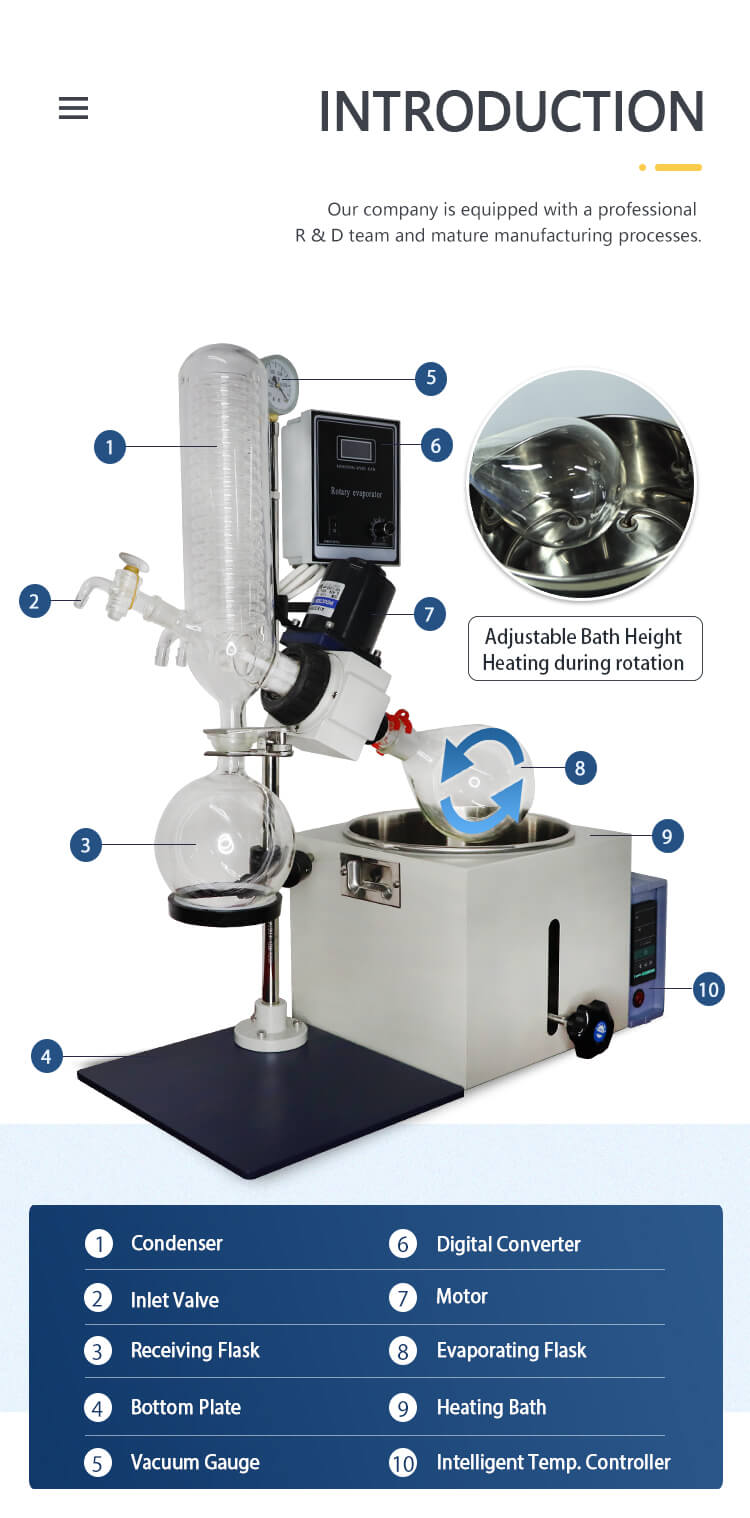

The rotary evaporator consists of a motor, a distillation flask, a heating pot, and a condenser tube. Since the flask is rotated through the evaporation course of, the floor space is bigger than normal which will increase the evaporation rate significantly. The solvent is collected in a flask and might properly be disposed off afterwards .

Rotary evaporators are one of many key steps in creating butane hash oil and different hashish concentrates. Using the rotary evaporator helps successfully concentrate the oil to a concentration of 15 to forty per cent. It additionally purges the solvents from the finished product and recovers them, making the oil exceptionally pure.

As a standard, the basic model has provision for digital display of Bath temperature, Vapour Temperature and RPM of the Rotary Flask. It also has controls to set the specified RPM and the specified Oil Bath Temperature. The receiving vessel has a short drip tube to ensure that the solvent drops down directly into the vessel and never flow alongside the partitions.

The water/oil bath is a heated bath which encloses the principle rotary flask and is used to indirectly heat the contents of the method. The rotary evaporator procedure could be very essential for environment friendly performance. Once the oil in the tub begins heating, and this warmth is indirectly passed to the process feed inside the flask.

This is certainly one of the most important applications of this system. Because of the superior know-how, it could improve the cooking ability. Always empty the solvent assortment flask of the unit immediately after use to prevent by chance mixing of incompatible materials or unidentified waste.10L Rotovap cannot be used for air and water-sensitive supplies. Highly reactive supplies should also not be rotovaped to stop injury to seals. Distillation is a more acceptable alternative for solvent removal for these items.

With so many software functions, there is no doubt that a rotary evaporator may be utilized in plenty of areas. For example, it can be used within the small and pilot experiments and manufacturing in the organic, pharmaceutical, chemical fields and even food-making industries. If you want a rotary evaporator, check out the in depth array of laboratory merchandise supplied at ZZKD Equipment.ZZKD is a leading supplier of latest and used laboratory equipment out there at incredible prices.

Rotary Evaporator Worth, 2022 Rotary Evaporator Worth Producers Suppliers

Rotary evaporation utilizing a conventional rotovap is extraordinarily helpful however extremely inefficient, resulting in excessive usages costs and laboratory house needed. Rotary evaporation works on the principle that lowering the stress on the solvent results inside have a lower evaporation level than at atmospheric pressure. Rotary evaporation is used in each preparative and analytical natural chemistry and might assist customers in fractionating liquid-phase mixtures to illustrate their composition or to purify specific compounds of curiosity. Rotary evaporation utility is various and it's a process that's used by chemists in client good manufacturing, biotechnology, prescription drugs, and extra. Water bath electrical lift and manual carry support, simple to make use of. The Science King 5L is a 5 Liter Rotary Evaporator system that makes use of the totally different boiling factors of supplies to separate the solvent materials from a combination.

The sealing is made of high quality and non-corrosive materials to ensure continued use. If you're looking for a Lab rotary evaporator to use in different fields, the above are prime greatest to assume about. They are made distinct options that make them best for use in various industries corresponding to magnificence, pharmaceutical and even in greater learning institutes.

This feature will forestall your solution from coming into the principle a part of the rotary evaporator. There is a three-way piston between the condenser tube and the stress decreasing pump. When the system is connected with the ambiance, the evaporation flask can be removed. When the system is related to the stress decreasing pump, the system must be underneath scale back pressure. A Swiss firm is the inventor of rotary evaporator. But right here, you can take pleasure in a a lot low-cost and prime quality rotovap.

Like in the case above, it has the flexibility to get rid of excess solvents from an answer. In this manner, it additionally manages to separate the solvent from the solution and likewise manages to recycle. Lastly, elevate the flask from the bathtub and take away the flask from the adapter.

To sum up, the trendy rotary evaporator can be used to distill the overwhelming majority of samples shortly and gently, even by operators with out operation experience. It is really helpful to use biotechnology merchandise. There is a three-way piston between the condenser tube and the decompression pump. When the system is linked with the rotating evaporator, the solvent may be transferred simply. When the system is connected with the decompression pump, the system should be in a decompression state.

Alternatively, the vacuum pump connection could be made at the receiver vent nozzle. Different configurations with single and double condensers are available depending on the appliance. The RTD is inserted contained in the vapour tube in a glass . This ensures that the contact elements are strictly Glass three.3 and PTFE solely and the metallic tip of PT-100 sensor does not are available direct contact with the process vapour. Depending on the design features, lots of completely different process possibilities are there, but the fundamental operating principle essentially remains as indicated above.

Rotary Evaporator, Reactor Molecular Distillation Equipment For Cbd Extraction Separation

The working process of a rotary evaporator can be roughly described beneath. At first, samples are placed in the evaporation flask. With the evaporation flask rotating at a continuing speed, there might be a thin movie of pattern contained in the evaporation flask, which facilitates evaporation price. Then extracted solvents are transferred into condenser and condensed into liquid from fuel. This entire course of takes place in a partial vacuum created by the vacuum pump.

Then we should cease first and then move via the atmosphere to prevent the rotating evaporator from falling off in rotation. And rotating evaporator can be geared up with a temperature tank. The water bath temperature shouldn't exceed the boiling point of the solvent. Increase the temperature of the tub slowly to keep away from bumping.

Lastly, raise the flask from the bath and take away the flask from the adapter. If it did not completely take away the solvent, add it again into the same flask and repeat the procedure. The speed of the rotor will rely upon the quantity of your pattern. The rotor ought to spin quick sufficient that it creates an even coating of the sample on the floor of the flask. Compared to its closest rival, distillation, the rotary evaporator is faster. Indeed, it yields the desired ends inside a shorter period of time.

It has excessive evaporation energy and enormous storage capacity, which suits large utility jobs. 10L rotary evaporator is an ideal example of the most effective system for distillation and different extraction devices. It is supplied with a sturdy working system that allows it to take away all the solvents and molecules from the chemical compounds.

A rotary evaporator will inevitably take in some mud and dust, which can affect the performance and shorten the service life. More seriously, the experimental effect might be instantly affected. Hence, the upkeep of a rotary evaporator should take the dust and pollution prevention as the principle duties. Clean a rotary evaporator properly and timely is an important part of instrument maintenance.

Traditional rotary evaporation setups contain the use of many interconnected devices and accessories, corresponding to a water bath, condenser tube, and rotating container flask. This setup is particularly designed for rotary evaporation, that means it's purpose-built and won't be used for any other experiments. Rotary evaporation is used for evaporation, crystallization, separation, drying, concentration, solvent recovery and is particularly used for the continual distillation of solvents underneath decreased stress. As there are so many various software purposes, there are heaps of industries that may benefit from the use of rotary evaporation similar to prescribed drugs, organic and food manufacturing.