How to use freeze dryer

This series is divided into KD-18N freeze dryer, KD-18ND freeze dryer, KD-12ND freeze dryer, KD-12N freeze dryer and other models. The vacuum freeze dryer is abbreviated as the freeze dryer. The vacuum freeze-dried items are easy to store for a long time. After adding water, they can return to the state before freeze-drying and maintain the original biochemical characteristics. It is resistant to heat-sensitive substances such as antibiotics, vaccines, blood products, and enzymes. Hormone and other biological tissues, freeze-drying technology is very suitable, widely used in medicine, pharmacy, biological research, chemical and food and other fields.

The vacuum freeze dryer is abbreviated as the freeze dryer. The vacuum freeze-dried items are easy to store for a long time. After adding water, they can return to the state before freeze-drying and maintain the original biochemical characteristics. It is resistant to heat-sensitive substances such as antibiotics, vaccines, blood products, and enzymes. Hormone and other biological tissues, freeze-drying technology is very suitable, widely used in medicine, pharmacy, biological research, chemical and food and other fields.

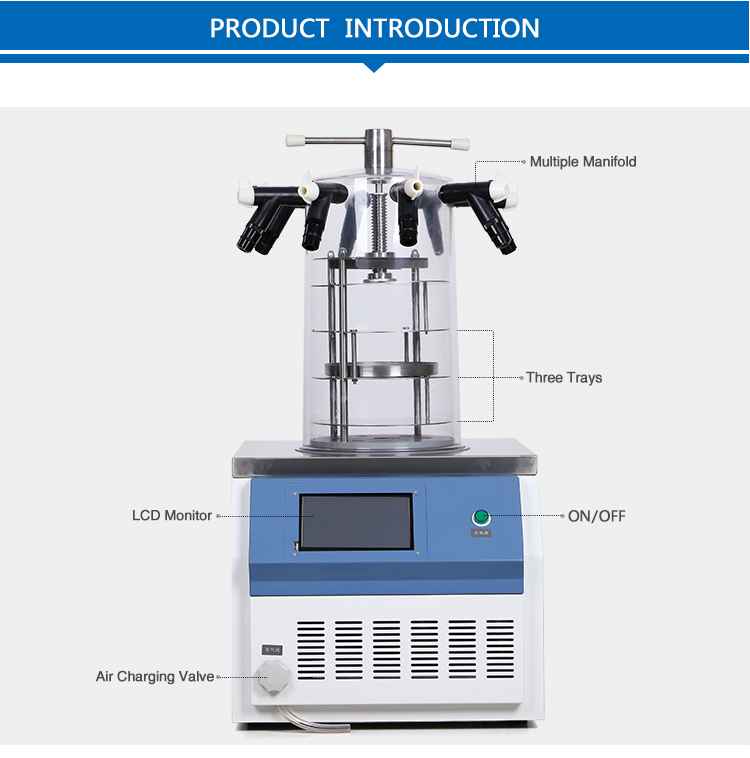

The freeze dryer (freeze dryer) is composed of a refrigeration system, a vacuum system, a heating system, and an electrical instrument control system. The main components are drying oven, condenser, refrigeration unit, vacuum pump, heating and cooling device, etc. Freeze-drying is abbreviated as freeze-drying, which is a method of freezing water-containing materials into a solid state, and then sublimating the water content from the solid state to a gaseous state to remove the water and preserve the material. The freeze-drying machine originated in the 1820s and the vacuum freeze-drying technology has experienced decades of ups and downs and has made great progress in the last 20 years. In the 21st century, vacuum freeze-drying technology has become more and more popular due to its incomparable advantages with other drying methods. In addition to being widely used in the fields of medicine, biological products, food, blood products, and active substances, its application scale and field It is still expanding. For this reason, vacuum freeze drying is bound to become an important application technology in the 21st century.

Freeze dryer use

1. Before starting each time, first check whether the pump oil in the vacuum pump is sufficient.

2. Unscrew the drain valve to let the remaining water flow out. Tighten the valve after draining.

3. Check whether the contact part between the freeze-drying chamber and the cold trap is intact, clean and readjust if necessary.

4. Close all valves (valves directly connected to the freeze-dried bottle, the white knob is up to close). Close the valve connecting the cold trap and the vacuum pump (at the back of the instrument, connected to the vacuum tube).

5. Turn on the power switch of the cold trap and turn on the power switch of the vacuum pump.

6. After 15 minutes, open the valve that connects the cold trap to the vacuum pump.

After 7.1 minutes, the pre-frozen sample (already in the freeze-drying bottle) can be hung on the holder, and the corresponding valve can be opened to start the freeze-drying process.

8. After the freeze-drying is complete, close the corresponding valve (white knob upwards), and remove the freeze-drying bottle. 9. After all the freeze-dried bottles are removed, turn off the power supply of the vacuum pump and the cold trap in turn.

10. After the frost in the cold trap has melted, open the drain valve to drain, and then close it.

Precautions

1. The sample must be pre-freeze before freeze-drying. The sample must be in a solid state (freezing state) before it can be freeze-dried. The longer the pre-freeze time, the better the freeze-drying effect. The sample volume should not exceed 13 of the sample bottle volume.

2. If the sample is thawed during freeze-drying and the vacuum pump and cold trap are in good working condition, the reason is that the vacuum is not enough and there is a leak. Please check whether all the valves are closed, whether the freeze-drying chamber and the surface of the cold trap are sealed, and if necessary, clean the surface of the cold trap and the sealing ring of the freeze-drying chamber.

3. Clean the cold trap cavity and freeze-drying cavity regularly.

4. It can be freeze-dried 15 minutes after starting up, the purpose is to pre-cool the cold trap and let the vacuum pump pre-heat. Only in this way can the instrument work in a best working condition.

5. After the valve is closed after the freeze-drying, the inside of the freeze-drying bottle communicates with the outside, and the bottle can be removed after the air pressure is balanced. 6. Clean the dust inside the compression bottle regularly, and refuel when the oil in the vacuum pump is low.

Vacuum freeze-drying technology has a wide range of applications in the fields of bioengineering, pharmaceutical industry, food industry, material science and deep processing of agricultural and sideline products. Freeze drying of medicines includes two parts: Western medicine and Chinese medicine. Freeze-drying of western medicines has achieved certain development in China, and many larger pharmaceutical factories have freeze-drying equipment. In terms of traditional Chinese medicine, it is currently only limited to the freeze-drying of a small amount of Chinese medicinal materials such as ginseng, deer antler, yam, and cordyceps. A large number of Chinese patent medicines have not yet adopted the freeze-drying process, which is far behind foreign countries. In the field of biotechnology products, freeze-drying technology is mainly used for the production of serum, plasma, vaccines, enzymes, antibiotics, hormones and other drugs; biochemical inspection drugs, immunology and bacteriology inspection drugs; blood, bacteria, arteries, bones , Skin, cornea, nerve tissue and various organs for long-term preservation.