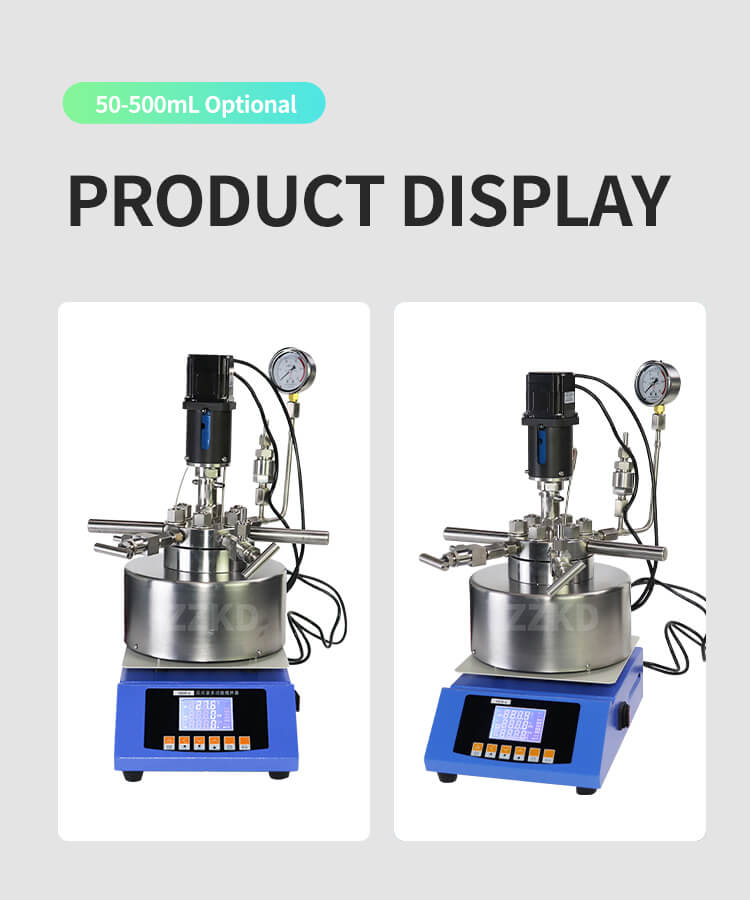

High Pressure Reactor Vessel: Revolutionizing Chemical and Pharmaceutical Processes

In the realm of modern chemistry and pharmaceuticals, the role of High pressure reactor manufacturers is nothing short of transformative. These vessels, designed to operate under extreme pressure conditions, have revolutionized the way various chemical and biological processes are conducted. As a laboratory equipment supplier with a rich history of 13 years, ZZKD Machinery and Instrument Equipment Co., Ltd. stands at the forefront of delivering cutting-edge high pressure reactor vessels that empower industries worldwide. In this article, we delve into the significance, applications, features, and benefits of high pressure reactor vessels, showcasing their pivotal role in driving innovation and progress.

Understanding High Pressure Reactor Vessels

A high pressure reactor vessel is a specialized container designed to withstand and facilitate chemical reactions and processes at significantly elevated pressures. This equipment is pivotal in industries such as pharmaceuticals, petrochemicals, material synthesis, and more. Unlike traditional reactors, high pressure reactor vessels enable researchers and engineers to explore reactions that are otherwise unattainable under standard atmospheric conditions. The ability to manipulate pressure empowers scientists to uncover novel synthesis routes, optimize reaction kinetics, and enhance product yields.

Applications across Industries of High Pressure Reactor Vessels

The versatility of high pressure reactor vessels is reflected in their widespread applications across diverse industries. In pharmaceuticals, these vessels play a critical role in the development of new drugs and pharmaceutical intermediates. High pressure conditions often lead to more efficient reactions, shorter reaction times, and improved selectivity, all of which contribute to accelerating drug discovery and development processes.

In the realm of petrochemicals, high pressure reactor vessels are utilized for hydrocracking, hydrotreating, and polymerization processes. These vessels enable the refinement of crude oil into valuable products, such as fuels and lubricants, by facilitating complex reactions that require elevated pressures.

Furthermore, high pressure reactor vessels find their place in material synthesis. From advanced ceramics to nanoparticles, the precise control over pressure conditions allows for the synthesis of materials with tailored properties, which is crucial for industries ranging from electronics to aerospace.

Features and Benefits of High Pressure Reactor Vessels

High pressure reactor vessels manufactured by ZZKD Machinery and Instrument Equipment Co., Ltd. are designed with meticulous attention to detail, ensuring optimal performance and safety. These vessels incorporate robust materials, state-of-the-art pressure control systems, and advanced sealing mechanisms to prevent leaks and ensure reliable operation under extreme conditions.

One of the key benefits of utilizing high pressure reactor vessels is the enhanced rate of reaction. Elevated pressures often lead to increased collision frequency among reactant molecules, resulting in faster reaction kinetics. This not only improves efficiency but also enables the exploration of reaction pathways that are not viable under standard conditions.

Another advantage is the improved yield and selectivity of desired products. High pressure conditions can favor specific reaction pathways, leading to higher yields of the target product and reduced formation of undesired by-products. This is particularly advantageous in industries where product purity and yield are of paramount importance.

Innovation in Action

ZZKD's commitment to innovation is evident in their high pressure reactor vessels. These vessels are equipped with advanced automation and control systems, allowing for precise regulation of pressure, temperature, and other process parameters. This level of control facilitates reproducibility and scalability of reactions, a crucial factor in transitioning from laboratory-scale research to industrial production.

Furthermore, ZZKD's global presence and strategic warehouse locations in the United States, Spain, and Thailand ensure prompt delivery and exceptional customer service. Their experienced OEM service further underscores their dedication to meeting unique customer specifications, offering tailor-made solutions that align with specific process requirements.

Conclusion

In conclusion, high pressure reactor vessels represent a pinnacle of engineering excellence that has catalyzed advancements in chemical and pharmaceutical industries. ZZKD Machinery and Instrument Equipment Co., Ltd. stands as a testament to the progress achieved in this field, with their 13 years of expertise and commitment to delivering top-tier equipment to clients across the globe. The impact of high pressure reactor vessels is far-reaching, enabling the synthesis of novel materials, the optimization of reaction pathways, and the acceleration of drug development. As industries continue to evolve, these vessels will undoubtedly remain a cornerstone of innovation, propelling us toward a future of enhanced efficiency and unparalleled discoveries.