Glass Reflux Condenser Reactor: Transforming Modern Laboratories

Introduction to Glass Reflux Condenser Reactors

Glass reflux condenser reactors are instrumental in contemporary laboratory setups. These devices epitomize precision and efficiency in various scientific processes. Understanding their role and functionality is crucial for labs aiming to stay ahead in research and development.

The Basic Concept

A 100l glass reactor functions on the principle of condensation and reflux, a method pivotal in many chemical reactions. It allows for the cooling and return of vapor back into the reaction mixture, ensuring optimal reaction conditions.

Importance in Research

These reactors are indispensable in research, especially in experiments requiring precise temperature control. Their transparency offers a clear view of the reactions, facilitating accurate observations and data collection.

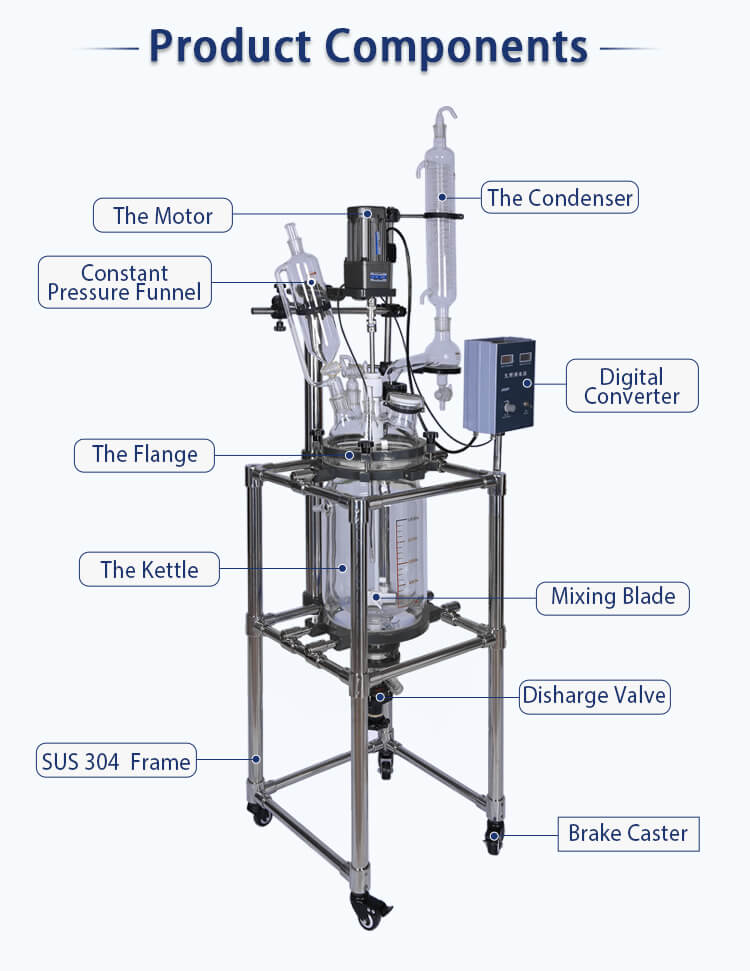

Design and Construction

The design of glass reflux condenser reactors is a marvel of modern engineering, combining functionality with safety.

Material Selection

Glass, often borosilicate due to its thermal resistance, is the primary material. This choice ensures durability under extreme conditions, including high temperatures and corrosive chemicals.

Structural Integrity

The construction of these reactors focuses on ensuring airtight seals and robust connections. This design minimizes risks and enhances the safety of laboratory personnel.

Operational Principles

Understanding the operational mechanics of glass reflux condenser reactors is key for effective utilization in laboratory environments.

The Reflux Process

The core principle revolves around the condensation of vapors and their subsequent return to the reaction vessel. This process is crucial for maintaining reaction consistency over prolonged periods.

Temperature Regulation

Precise temperature control is achievable due to the reactor's design. This aspect is vital for reactions sensitive to temperature variations.

Maintenance and Care

Proper maintenance is essential for the longevity and optimal performance of glass reflux condenser reactors.

Regular Cleaning

Regular cleaning and inspection are crucial to prevent contamination and ensure smooth operation. This also extends the life of the reactor.

Handling and Storage

Proper handling and storage are necessary to avoid damage. Glass reactors, while durable, require careful handling due to their material nature.

Safety Considerations

Safety is paramount when working with glass reflux condenser reactors, given the nature of substances and reactions involved.

Proper Training

Operators must be adequately trained in handling these reactors. Understanding their operation and potential hazards is critical for safe laboratory practices.

Emergency Protocols

Having well-established emergency protocols in place, including handling chemical spills and glass breakage, is essential for any laboratory using these reactors.

Conclusion: A Staple in Modern Labs

Glass reflux condenser reactors have become a staple in modern laboratories. Their precision, safety, and efficiency make them an invaluable tool in the pursuit of scientific advancement. While not delving into their features, advantages, or applications, it's clear that these reactors play a pivotal role in various research and development endeavors.

For further information and inquiries, contact ZZKD Machinery and Instrument Equipment Co., Ltd., your trusted partner in advanced laboratory solutions.