Buy Glass Vessel Chemical Reactors: A Guide for Laboratories and Industrial Applications

In the realm of chemical synthesis, analysis, and processing, the need for high-quality and reliable equipment is paramount. Among these, glass vessel chemical reactors stand out for their versatility, visibility, and durability in various chemical reactions. This article delves into the world of these reactors, focusing on why you should consider buying glass vessel chemical reactors for your laboratory or industrial needs, highlighting a popular option like the 100l glass reactor.

Understanding Glass Vessel Chemical Reactors

Glass vessel chemical reactors are essential tools in any chemistry lab. They are designed to withstand a range of temperatures and pressures, making them suitable for a wide array of chemical reactions. The transparent glass construction allows for easy monitoring of the reaction process, ensuring safety and precision in your experiments.

The Benefits of Glass Reactors

Glass reactors are renowned for their chemical resistance and inertness. They do not react with most chemicals, ensuring purity in your experiments. Their transparency allows for easy monitoring of reactions, and they are relatively easy to clean, maintaining a contaminant-free environment.

Types of Glass Reactors

There are various types of glass reactors, such as batch reactors, continuous stirred-tank reactors (CSTR), and plug flow reactors. Each type serves different purposes, catering to specific reaction needs and scales.

Why Buy Glass Vessel Chemical Reactors?

Investing in a glass reactor can significantly enhance the efficiency and safety of your chemical processes. These reactors are versatile, accommodating a broad range of reactions, from simple synthesis to complex organic transformations.

Efficiency and Control

Glass reactors offer precise control over reaction conditions, including temperature and mixing speed. This control is crucial for achieving desired reaction outcomes and reproducibility.

Safety Considerations

The strength and transparency of glass reactors provide an added layer of safety. They allow for easy detection of any changes in the reaction mixture, helping prevent accidents and ensure the safety of lab personnel.

The 100l Glass Reactor: An Ideal Choice

For those requiring larger-scale reactions, the 100l glass reactor is an ideal choice. It combines capacity with the inherent advantages of glass reactors, making it suitable for both research and industrial applications.

Features and Applications

The 100l glass reactor is equipped with features like temperature control, variable stirring speeds, and can be customized with additional fittings. It's perfect for scaling up reactions or conducting pilot studies.

Choosing the Right Model

Selecting the right model depends on your specific needs, such as reaction volume, temperature range, and required features like condensers or feed ports.

Maintenance and Care of Glass Reactors

Proper maintenance is key to ensuring the longevity and performance of your glass reactor. Regular cleaning and inspection are necessary to maintain its integrity and functionality.

Cleaning Procedures

Cleaning glass reactors involves disassembling removable parts and using appropriate solvents to remove residues. Care must be taken to avoid damaging the glass.

Regular Maintenance Checks

Regular checks for any signs of wear or damage are crucial. Seals and gaskets should be inspected and replaced as needed to ensure airtight operation.

Applications in Various Industries

Glass vessel chemical reactors are not limited to academic research; they find applications in various industries such as pharmaceuticals, biotech, and chemical manufacturing.

Pharmaceutical Industry

In pharmaceuticals, glass reactors are used for synthesizing and purifying chemical compounds, crucial in drug development.

Biotechnology and Chemical Manufacturing

They are also pivotal in biotech for conducting controlled biochemical reactions, and in chemical manufacturing for producing a wide range of chemicals safely and efficiently.

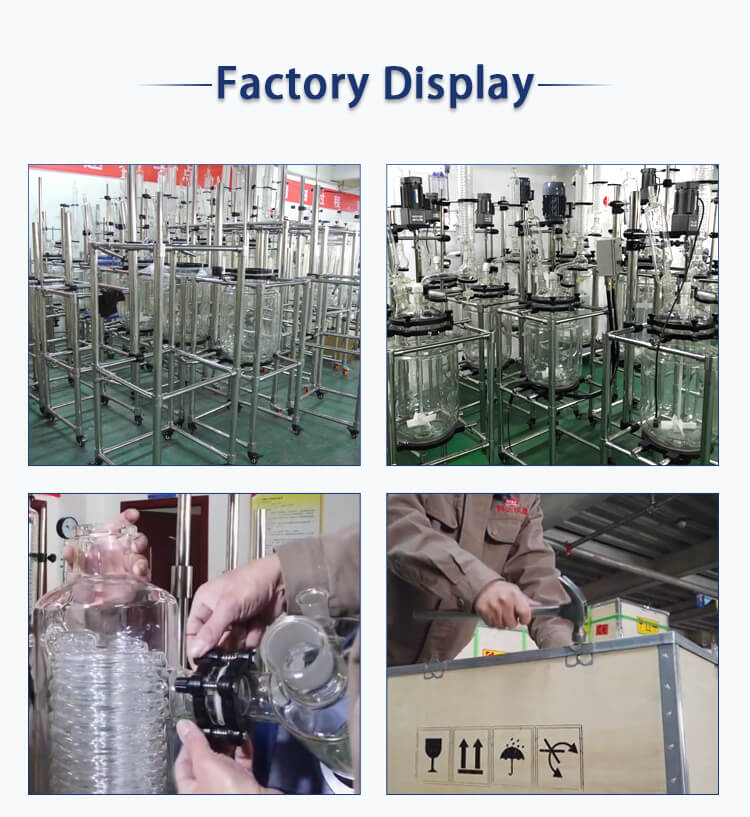

Conclusion: Why Choose ZZKD for Your Glass Reactor Needs

When looking to buy glass vessel chemical reactors, it's essential to choose a reliable supplier. ZZKD Machinery and Instrument Equipment Co.,Ltd. stands out as a leader in this field, offering high-quality distillation and extraction equipment, including the 100l glass reactor. With 13 years of experience in manufacturing and exporting globally, ZZKD provides professional sales and technical support, ensuring you get the perfect solution for your chemical processing needs.

If you're interested in enhancing your laboratory or industrial processes with a high-quality glass reactor, visit ZZKD's website to explore our range of products. Our team is ready to provide you with tailored solutions and support, ensuring you make the best investment for your needs. Don't hesitate, explore our products and take the first step towards optimizing your chemical processes today.