Autoclave Stirred Tank Reactor: A Versatile Tool for Chemical Processing

In the realm of chemical engineering, the autoclave stirred tank reactor (ASTR) is a crucial apparatus that finds extensive applications in various industries. With its unique design and capabilities, the Autoclave Stirred Tank Reactor enables efficient and controlled chemical reactions, making it a preferred choice for numerous processes. In this article, we will delve into the working principles, applications, and advantages of the autoclave stirred tank reactor, high pressure reactor manufacturers, showcasing its significance in modern chemical engineering.

1. Understanding the Autoclave Stirred Tank Reactor

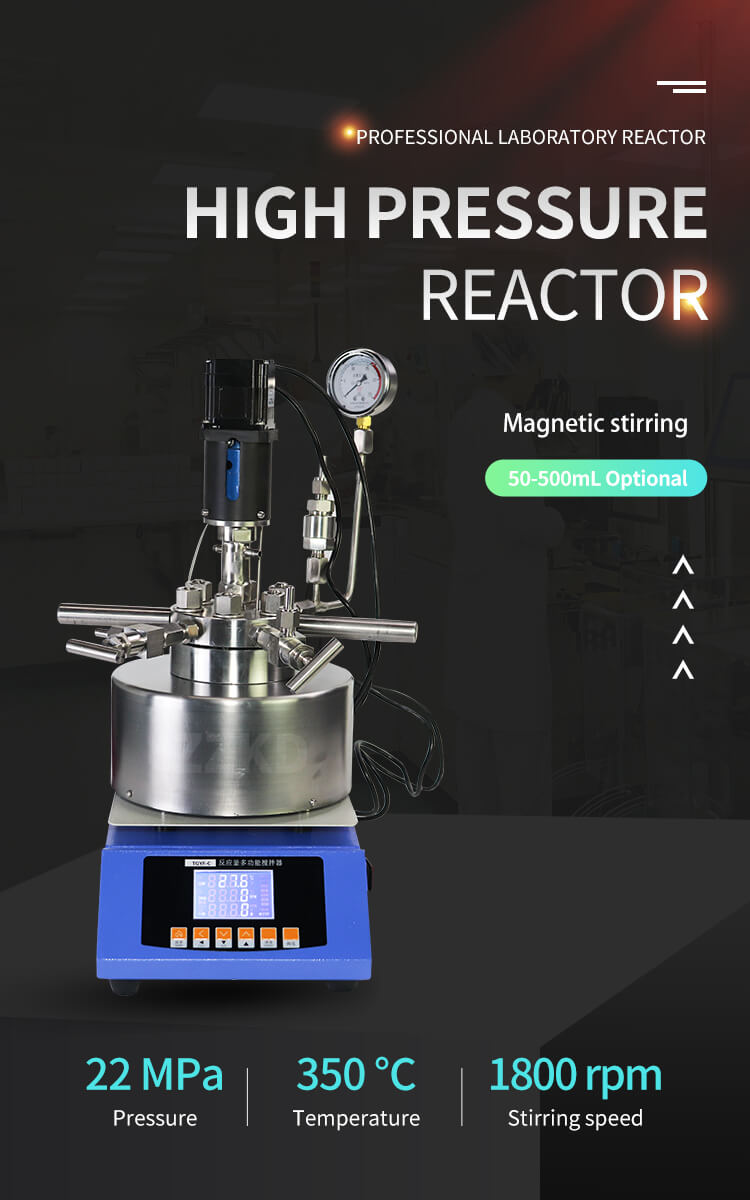

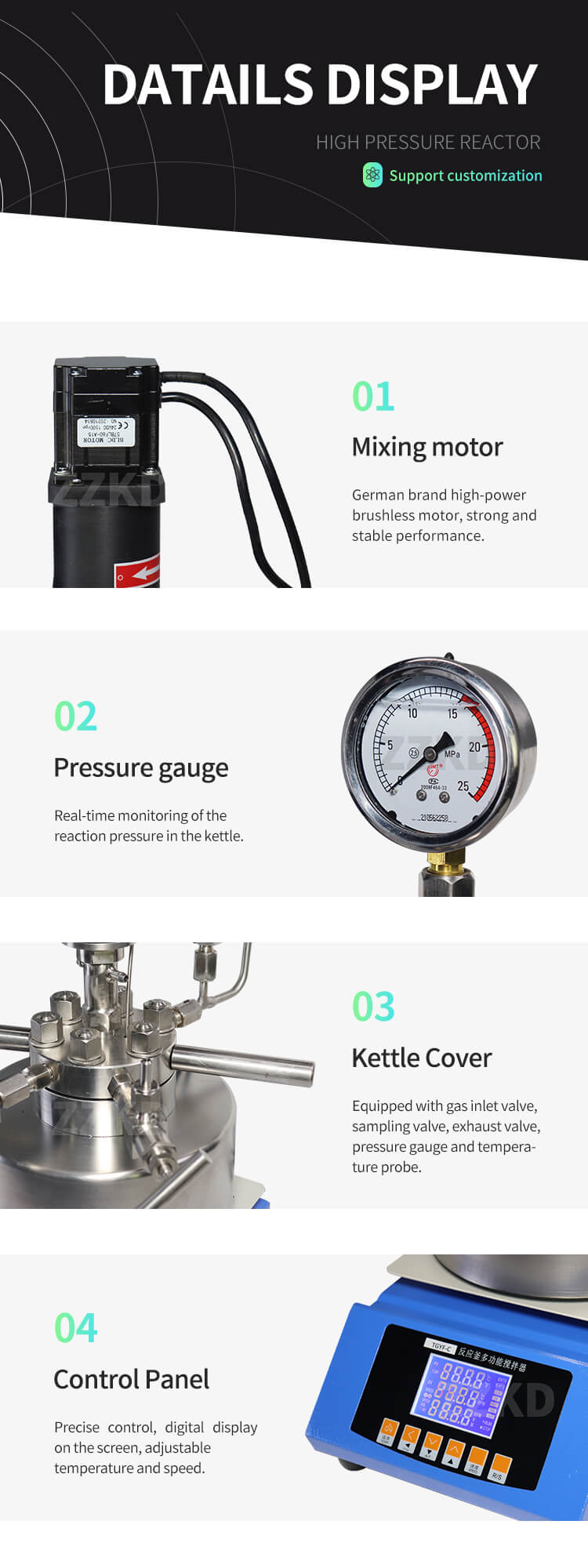

The autoclave stirred tank reactor, also known as the ASTR, is a vessel designed to facilitate chemical reactions under high-pressure, high-temperature conditions. It consists of a cylindrical chamber with an agitator system, heating and cooling mechanisms, and a pressure control system. The agitator system comprises impellers or blades that promote efficient mixing of reactants, ensuring uniform distribution and enhancing reaction rates.

2. Working Principles of the Autoclave Stirred Tank Reactor

The Autoclave Stirred Tank Reactor operates on the principles of heat transfer, mass transfer, and reaction kinetics. The reactor's primary function is to maintain the desired reaction conditions by precisely controlling temperature, pressure, and reactant concentration. The heating and cooling mechanisms, often implemented through a jacket or a coil, allow for efficient heat exchange, ensuring the desired temperature is reached and maintained.

3. Key Advantages of the Autoclave Stirred Tank Reactor

The autoclave stirred tank reactor offers several advantages that make it an indispensable tool in chemical processing. These advantages include:

a. Enhanced Mixing: The agitator system in the Autoclave Stirred Tank Reactor ensures thorough mixing of reactants, eliminating concentration gradients and enhancing reaction efficiency.

b. Improved Heat Transfer: The Autoclave Stirred Tank Reactor's heating and cooling mechanisms enable efficient heat transfer, allowing precise temperature control for optimal reaction rates.

c. Versatility: The Autoclave Stirred Tank Reactor can accommodate a wide range of reaction conditions, including high pressures and temperatures, making it suitable for diverse chemical processes.

d. Scalability: The Autoclave Stirred Tank Reactor can be easily scaled up or down, enabling seamless transition from laboratory-scale experiments to industrial production.

4. Applications of the Autoclave Stirred Tank Reactor

The autoclave stirred tank reactor finds applications in various industries, including:

a. Pharmaceutical Industry: The Autoclave Stirred Tank Reactor plays a crucial role in pharmaceutical manufacturing, allowing precise control over chemical reactions and ensuring consistent product quality. It is commonly used for processes such as hydrogenation, esterification, and hydrolysis.

b. Petrochemical Industry: In the petrochemical sector, the Autoclave Stirred Tank Reactor facilitates reactions involved in the production of fuels, polymers, and other important chemicals. It enables processes like polymerization, alkylation, and oxidation.

c. Specialty Chemicals: The Autoclave Stirred Tank Reactor is extensively employed in the production of specialty chemicals, including fine chemicals, agrochemicals, and dyes. It offers the necessary control and efficiency required for intricate and sensitive reactions.

5. Case: Autoclave Stirred Tank Reactor in Biodiesel Production

To illustrate the practical application of the autoclave stirred tank reactor, let us consider its use in the production of biodiesel. Biodiesel is a renewable and environmentally friendly alternative to conventional diesel fuel, derived from vegetable oils or animal fats through a process known as transesterification.

In the transesterification reaction, the Autoclave Stirred Tank Reactor allows for the efficient mixing of vegetable oil or animal fat with an alcohol, typically methanol or ethanol, in the presence of a catalyst such as sodium hydroxide or potassium hydroxide. The Autoclave Stirred Tank Reactor's precise temperature and pressure control, coupled with effective mixing, promote the conversion of the triglycerides in the feedstock into biodiesel and glycerol.

By employing the Autoclave Stirred Tank Reactor, biodiesel manufacturers can achieve high yields and minimize unwanted byproducts. The reactor's design enables the continuous flow of reactants, ensuring uniform conversion and reducing the formation of impurities. Additionally, the scalability of the Autoclave Stirred Tank Reactor allows for the smooth transition from laboratory-scale to large-scale production, supporting the growth of the biodiesel industry.

The autoclave stirred tank reactor is a versatile and indispensable tool in chemical engineering, offering enhanced mixing, precise temperature control, and scalability. Its applications span across various industries, including pharmaceuticals, petrochemicals, and specialty chemicals. The biodiesel production case study demonstrates the Autoclave Stirred Tank Reactor's effectiveness in achieving high yields and product quality. As advancements in chemical engineering continue, the Autoclave Stirred Tank Reactor will remain a cornerstone of modern industrial processes, driving innovation and sustainable development.