Alcohol Recovery Machine

Solvents are widely used in many industrial processes, including chemical production, pharmaceutical manufacturing, and printing. However, solvents can be costly and have a negative impact on the environment. Alcohol Recovery Machines offer a solution by allowing companies to recycle and reuse solvents, reducing costs and minimizing environmental impact. In this article, we will explore what Solvent recovery machine are, how they work, and their potential benefits.

What is a Alcohol Recovery Machine?

A Alcohol Recovery Machine is a device that recycles solvents used in industrial processes. Alcohol Recovery Machines work by separating the solvent from the waste material, purifying it, and returning it to the manufacturing process. This reduces the amount of waste generated by the process and allows companies to reuse solvents, reducing costs and minimizing environmental impact.

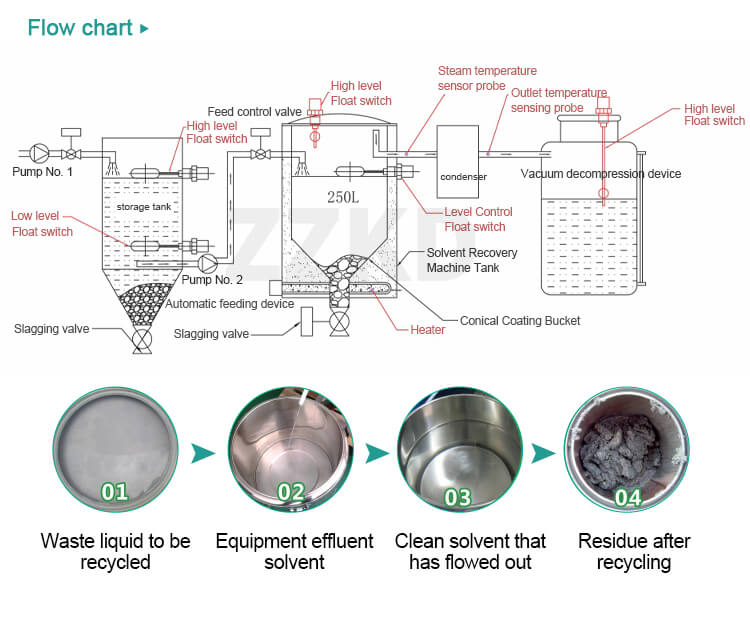

How Does a Alcohol Recovery Machine Work?

Alcohol Recovery Machines work by using a process called distillation. Distillation is a process that separates a mixture of liquids into its individual components based on their boiling points. In the case of Alcohol Recovery Machines, the machine heats the waste material containing the solvent until it reaches its boiling point, causing the solvent to evaporate. The solvent vapor is then condensed back into its liquid form, purified, and returned to the manufacturing process.

There are two types of Alcohol Recovery Machines: batch and continuous. Batch machines process a fixed amount of waste material at a time, while continuous machines can process waste material continuously. Continuous machines are typically more efficient than batch machines, but they are also more expensive.

Benefits of a Alcohol Recovery Machine:

Alcohol Recovery Machines offer several benefits for industrial processes that use solvents. Some of these benefits include:

1. Cost Savings:

Alcohol Recovery Machines allow companies to reuse solvents, reducing the amount of new solvent needed for the manufacturing process. This can lead to significant cost savings over time.

2. Environmental Benefits:

Alcohol Recovery Machines reduce the amount of waste generated by industrial processes, minimizing the environmental impact of these processes. This is especially important for solvents that are hazardous to the environment, such as those that are flammable or toxic.

3. Improved Process Efficiency:

Alcohol Recovery Machines can improve the efficiency of industrial processes by allowing companies to reuse solvents. This reduces the amount of time and resources needed to produce new solvents, improving the overall efficiency of the manufacturing process.

4. Regulatory Compliance:

Many countries have regulations regarding the disposal of hazardous waste, including solvents. Alcohol Recovery Machines can help companies comply with these regulations by reducing the amount of hazardous waste generated by the manufacturing process.

Limitations of a Alcohol Recovery Machine:

While Alcohol Recovery Machines offer several benefits, there are also some limitations to consider. Some of these limitations include:

1. Upfront Cost:

Alcohol Recovery Machines can be expensive to purchase and install. This can be a significant barrier to adoption, especially for smaller companies that may not have the financial resources to invest in this technology.

2. Maintenance Requirements:

Alcohol Recovery Machines require regular maintenance to operate efficiently. This includes cleaning and replacing parts as needed. Failure to maintain the machine properly can lead to reduced efficiency and increased costs over time.

3. Compatibility Issues:

Not all solvents are compatible with Alcohol Recovery Machines. Some solvents may have impurities that cannot be removed using distillation, while others may react with the machine's components. This can limit the types of solvents that can be reused, reducing the potential cost savings and environmental benefits.

4. Space Requirements:

Alcohol Recovery Machines can be large and require a significant amount of space to operate. This can be a challenge for companies with limited space in their facilities.

Alcohol Recovery Machines offer a promising solution for companies that use solvents in their industrial processes. By allowing companies to recycle and reuse solvents, these machines can reduce costs, improve process efficiency, and minimize environmental impact. While there are limitations to consider, the benefits of Alcohol Recovery Machines are significant and can have a positive impact on both the company and the environment.

As technology continues to advance, Alcohol Recovery Machines are becoming more efficient and effective. Newer models are designed to handle a wider range of solvents and can operate continuously, further improving their efficiency. This makes Alcohol Recovery Machines an increasingly attractive option for companies looking to reduce costs and minimize their environmental impact.

Alcohol Recovery Machines are a valuable tool for companies that use solvents in their industrial processes. By recycling and reusing solvents, these machines can help companies reduce costs, improve efficiency, and minimize their environmental impact. While there are limitations to consider, the benefits of this technology are significant and have the potential to make a positive impact on the world. As companies continue to adopt Alcohol Recovery Machines, we can expect to see even greater advancements in this field, further improving the efficiency and effectiveness of this valuable technology.