- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

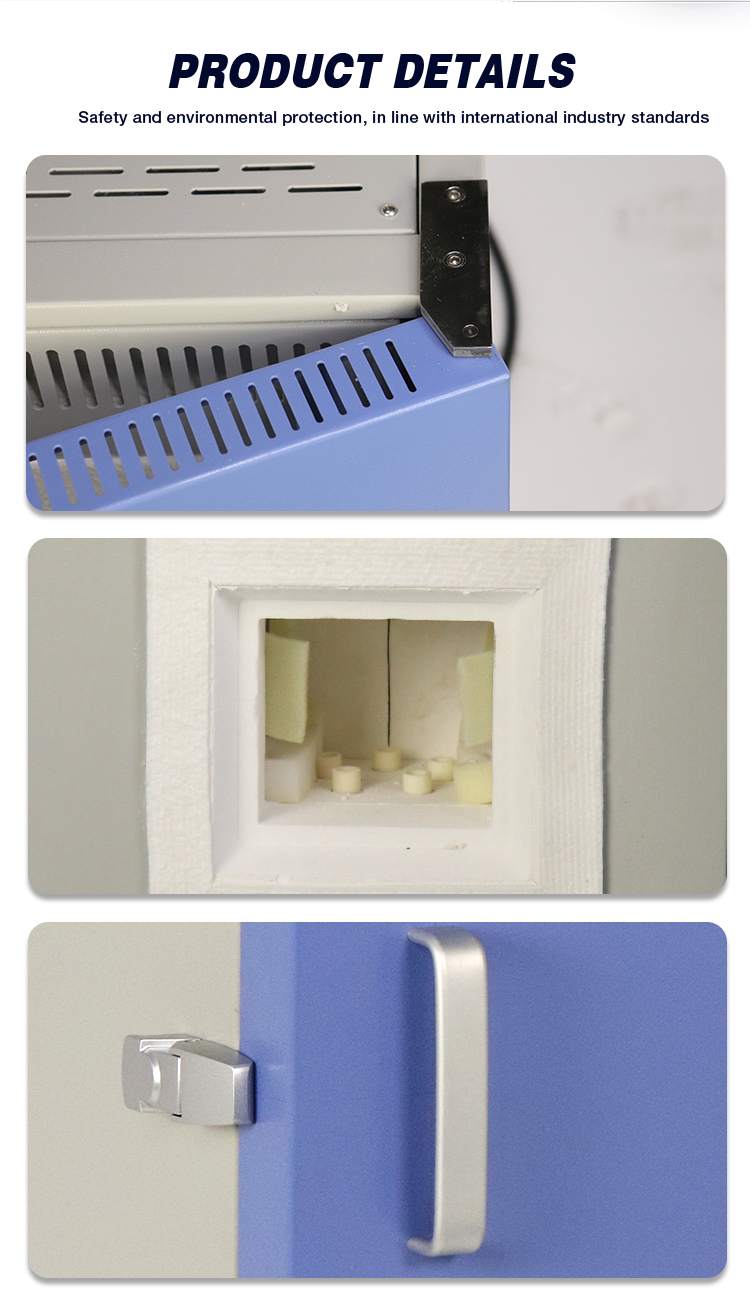

Advantage:

The muffle furnace is made of vacuum-formed high-purity alumina multi-light material, which has low heat storage, excellent heat preservation and energy saving effects, and greatly reduces the total weight of the electric furnace. The double-layer air-cooled structure ensures that the surface temperature of the furnace shell is close to room temperature. The temperature control system adopts industrial grade 0.2 intelligent instrument, PID control, 51-segment heating curve, high degree of automation. The laboratory of the institute and industrial and mining enterprises are ideal equipment for sintering, melting, analysis and development of metals, non-metals and other composite materials.

Features:

1.Light weight, fast heating, saving time and effort, and good energy saving effect.

2.The control system has a modular structure, easy maintenance, long-life design of key equipment components, simple and reliable process, good stability and high precision.

3.Control method: SCR control, PID parameter self-tuning function, manual/automatic non-interference switching function, over-temperature alarm function, programmable more than 30 sections.

4.Display window: measuring temperature, dual display of set temperature, heating power bar display.

5.Heating speed: freely set within 9999 minutes, generally it can rise to 800°C within 10 minutes.

6.Furnace material: using composite ceramic fiber material, it has the characteristics of vacuum forming and no powder falling at high temperature.

7.Rushing temperature value: ≤1-3℃, heating power can be adjusted automatically according to the setting temperature rise, highlighting the energy-saving effect.

8.Control display accuracy: ±1℃.

9.Instrument accuracy: 0.2% F.S.

10.Temperature uniformity: ±1℃.

After sale:

Free maintenance for life

Technical engineers can receive overseas training

Remote technical consultation

Video guide installation

Free replacement of some accessories

FAQ:

How to use the muffle furnace:

1. After unpacking the new muffle furnace, first check whether the muffle furnace is intact and whether the spare parts are complete. The general muffle furnace does not require special installation, and only needs to be placed flat on the indoor flat floor or shelf. The controller should avoid vibration, and the location should not be too close to the electric furnace to prevent internal components from malfunctioning due to overheating of the controller.

2. An additional power switch needs to be installed at the lead-in of the power cord to control the total power supply. In order to ensure safe operation, the controller must be reliably grounded.

3. If there is a thermocouple, insert it into the furnace by 20-50mm. The gap between the hole and the thermocouple must be filled with asbestos rope. It is better to use compensation wire (or insulated steel core wire) to connect the thermocouple to the control, distinguish the positive and negative poles, and do not reverse the connection.

4. Before use, the thermometer indicator should be adjusted to the zero point. If the compensation wire and cold junction compensator are used, the mechanical zero point should be adjusted to the reference temperature point of the cold junction compensator; when the compensation wire is not used, then The mechanical zero point is adjusted to the zero scale position, but the temperature indicated is the temperature difference between the measuring point and the cold junction of the thermocouple.

5. After checking the wiring and confirming that it is correct, cover the controller shell. Adjust the temperature indication of the temperature indicator to the required operating temperature, and then turn on the controller. Turn on the working power switch, at this time the green light on the temperature indicating instrument lights up, the relay starts to work, the electric furnace is energized, and the ammeter displays the current. As the internal temperature of the electric furnace continues to rise, the temperature indicated by the temperature indicator also gradually rises. This phenomenon indicates that the system is working normally.

The muffle furnace has the following classifications according to its heating element, temperature and controller:

1. According to the heating elements, there are: electric furnace wire muffle furnace, silicon carbide rod muffle furnace, silicon molybdenum rod muffle furnace;

2.Divided according to the temperature of use, generally divided into: box muffle furnace below 1000 degrees, 1100 degrees to 1300 degrees muffle furnace (silicon carbide rod muffle furnace), silicon molybdenum rod muffle furnace above 1600 degrees;

3. According to the controller, there are the following types: PID adjustment control muffle furnace (SCR digital display temperature controller), program control muffle furnace (computer time temperature program controller);

4. According to the insulation materials, there are two types: ordinary refractory brick muffle furnace and ceramic fiber muffle furnace.

The daily operating procedures of the muffle furnace:

1. Do not exceed the maximum temperature of the resistance furnace during use;

2. Be sure to cut off the power when loading and taking samples to prevent electric shock;

3. The opening time of the furnace door should be as short as possible when loading and taking samples to extend the service life of the electric furnace;

4. It is forbidden to pour any liquid into the furnace;

5. Do not put samples stained with water and oil into the furnace; do not use clips stained with water and oil to pick up the samples;

6. Wear gloves when loading and taking samples to prevent burns;

7. The sample should be placed in the middle of the furnace, neatly placed, and do not place it randomly;

8. Do not touch the electric furnace and surrounding samples casually;

9. Cut off the power and water source after use;

10. Do not operate the resistance furnace without the permission of the management personnel, and operate in strict accordance with the operating procedures of the equipment.

Mode | KD-BR-12N | KD-BR-14S | KD-BR-17M |

Furnace size(mm) | 100X100X100, 200X200X200,300X300X300, 300X300X400,400X400X400,customize | ||

Maximum temperature(℃) | 1200 | 1400 | 1700 |

Operating temperature(℃) | 1100 | 1300 | 1600 |

Heating rate (℃/ min) | 20 | 15 | 15 |

Temperature control accuracy | ±1 | ±1 | ±1 |

Heating element | Molybdenum resistance wire | Silicon carbide rod | Silicon molybdenum rod |

Rated voltage | 220,380 | ||

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap