- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

In the world of laboratories and research facilities, precision and efficiency are of paramount importance. When it comes to mixing and emulsification processes, a reliable and versatile tool is essential. Enter the lab emulsifying mixer machine, a cutting-edge device designed to streamline laboratory operations and produce consistent results. In this article, we will explore the features, benefits, and applications of the lab emulsifying mixer machine, highlighting its crucial role in scientific research and development.

The lab emulsifying mixer machine is a sophisticated laboratory instrument that integrates mixing and emulsification processes into a single device. It is designed to handle small to medium-scale operations, providing scientists and researchers with the ability to produce homogenous mixtures and stable emulsions efficiently. With precise control over mixing speed, temperature, and other parameters, this machine offers versatility and accuracy in a laboratory setting.

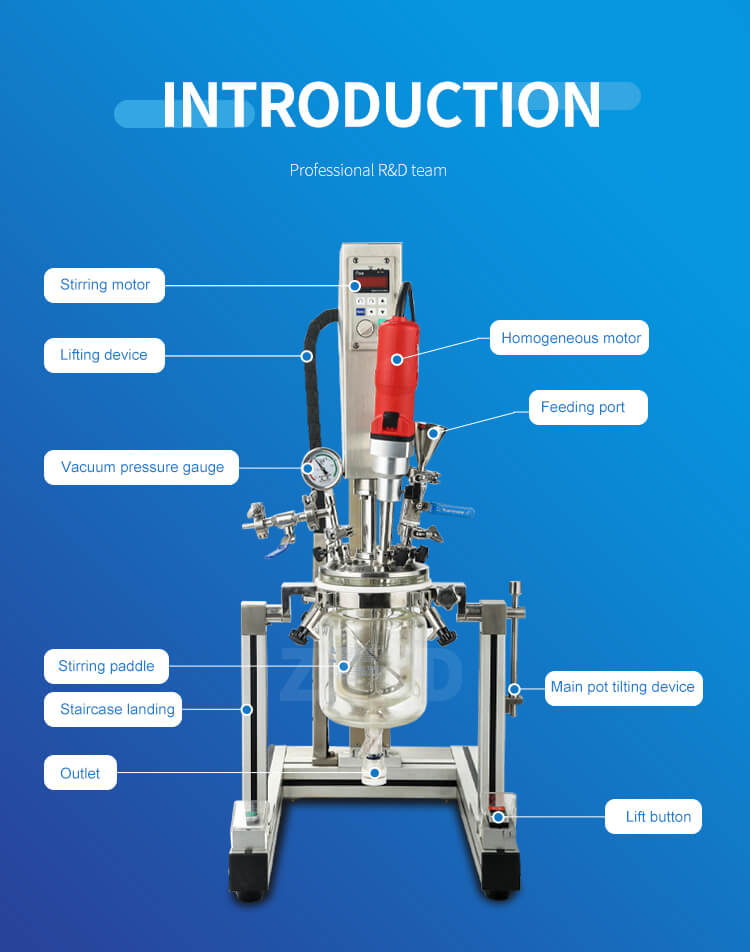

The lab emulsifying mixer machine boasts several notable features that contribute to its efficiency and performance. These features include:

a. Variable Speed Control: The machine allows users to adjust the mixing speed according to their specific requirements. This feature enables optimal mixing and emulsification for various substances, ensuring consistent results.

b. Temperature Control: Some lab emulsifying mixer machines offer temperature control capabilities, allowing users to maintain the desired temperature during the mixing process. This feature is particularly beneficial when working with temperature-sensitive substances.

c. Multiple Mixing Modes: The machine typically offers different mixing modes, such as blending, homogenizing, dispersing, and emulsifying. These modes cater to various research needs, ensuring the successful production of desired mixtures and emulsions.

d. User-Friendly Interface: Lab emulsifying mixer machines often come equipped with an intuitive control panel or digital interface, making it easy for users to set parameters, monitor progress, and make adjustments as needed.

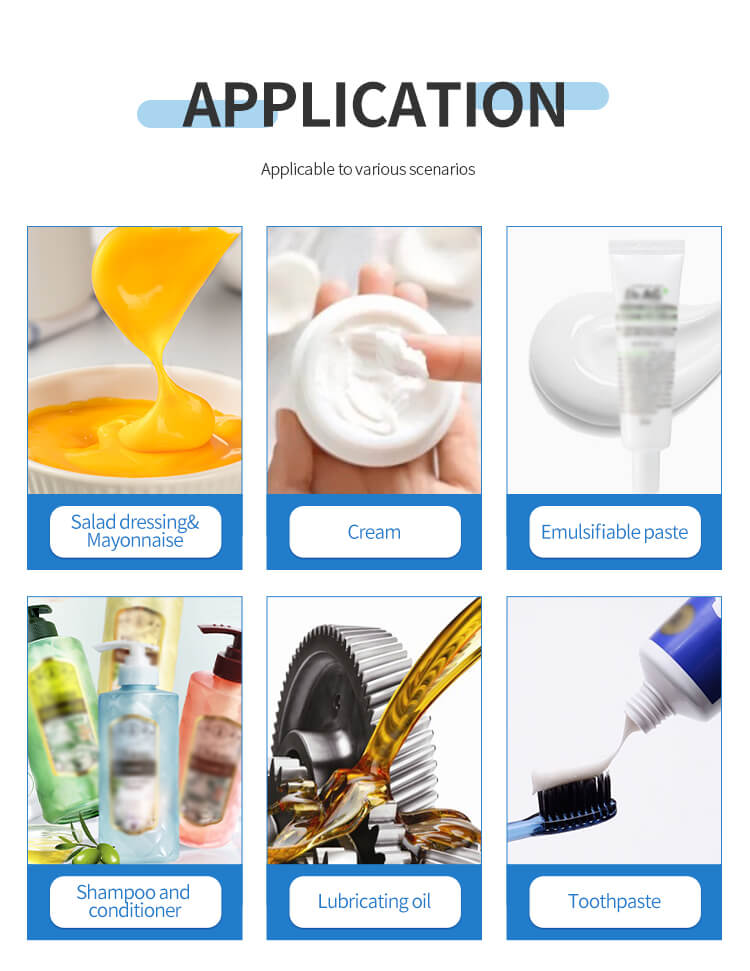

The lab emulsifying mixer machine finds its applications across a wide range of scientific disciplines, including pharmaceuticals, cosmetics, food and beverages, chemical research, and more. It is used for tasks such as:

a. Formulation Development: Researchers rely on lab emulsifying mixer machines to develop new formulations by blending various components, ensuring uniformity and stability in the final product.

b. Sample Preparation: In laboratories, samples often require homogenization before further analysis. The lab emulsifying mixer machine offers a quick and efficient solution for preparing samples with consistent properties.

c. Emulsion Production: Emulsions play a vital role in various industries, including pharmaceuticals and cosmetics. The lab emulsifying mixer machine enables the production of stable emulsions by combining immiscible substances.

Investing in a lab emulsifying mixer machine yields numerous benefits for researchers and scientists, including:

a. Time and Cost Savings: The machine's efficiency and automation streamline laboratory processes, reducing the time and effort required for manual mixing and emulsification. This, in turn, leads to significant cost savings in terms of labor and resources.

b. Enhanced Precision: The ability to control mixing parameters allows for precise adjustments, ensuring consistent and reproducible results. This precision is crucial in research and development, where accuracy is paramount.

c. Increased Productivity: With faster mixing cycles and improved performance, lab emulsifying mixer machines boost productivity in laboratory settings. Researchers can accomplish more experiments within a given timeframe, accelerating the pace of their work.

The lab emulsifying mixer machine operates on the principle of high shear mixing, where two or more substances are subjected to intense mechanical forces to achieve uniform blending or emulsification. The machine utilizes specialized tools, such as rotor-stator assemblies or high-speed rotors, to create intense turbulence and shear stress, breaking down particles and promoting mixing.

When selecting a lab emulsifying mixer machine, it is essential to consider several factors:

a. Capacity and Scale: Determine the required volume and scale of your operations to choose a machine that can accommodate your specific needs.

b. Mixing Speed Range: Ensure the machine offers a wide range of mixing speeds to cater to different substances and research requirements.

c. Material Compatibility: Verify that the materials used in the machine's construction are compatible with the substances you intend to mix or emulsify.

d. Ease of Cleaning and Maintenance: Opt for a machine that is easy to clean and maintain, as this contributes to its longevity and reliability.

The field of lab emulsifying mixer machines is constantly evolving, with ongoing innovations to enhance performance and functionality. Some of the promising advancements include:

a. Automation and Integration: Integration with laboratory automation systems and enhanced programmability allows for seamless integration into larger laboratory workflows.

b. Advanced Monitoring and Control: Incorporating advanced sensors and real-time monitoring capabilities enables precise control over mixing parameters and enhanced process optimization.

c. Nanoscale Emulsification: Researchers are exploring ways to achieve emulsification at the nanoscale, opening up new possibilities in drug delivery systems and other cutting-edge applications.

The lab emulsifying mixer machine is an indispensable tool in modern laboratories, revolutionizing the mixing and emulsification processes. Its versatile nature, precise control, and efficiency make it a valuable asset for scientists and researchers across various industries. As technology continues to advance, we can expect further innovations that will propel laboratory operations to new heights, enabling groundbreaking discoveries and advancements in numerous scientific fields.

Q: What is a lab emulsifying mixer machine?

A: A lab emulsifying mixer machine is a piece of equipment used in laboratories and research facilities for blending, dispersing, and emulsifying various substances. It is designed to mix two or more immiscible liquids or liquids and solids together to create a stable emulsion or dispersion.

Q: How does a lab emulsifying mixer machine work?

A: A lab emulsifying mixer machine works by utilizing a high-speed rotating impeller or a rotor-stator arrangement. The impeller or rotor-stator generates intense mechanical forces that cause the substances to mix and undergo shearing, turbulence, and intense agitation. This helps break down larger particles and promote uniform mixing and dispersion.

Q: What are the typical applications of a lab emulsifying mixer machine?

A: A lab emulsifying mixer machine is commonly used in various scientific and research applications. Some typical uses include creating pharmaceutical emulsions, mixing and dispersing pigments in the cosmetic industry, blending ingredients for food and beverage production, formulating creams and lotions in the personal care industry, and conducting chemical reactions in laboratories.

Q: What are the advantages of using a lab emulsifying mixer machine?

A: There are several advantages to using a lab emulsifying mixer machine. Firstly, it offers precise control over mixing parameters such as speed, shear rate, and duration, allowing for reproducible and consistent results. Secondly, it facilitates the production of stable emulsions and dispersions with reduced particle size distribution. Additionally, it saves time and effort compared to manual mixing methods and enables scalability for potential industrial production.

Q: How do I select the right lab emulsifying mixer machine for my needs?

A: When selecting a lab emulsifying mixer machine, consider factors such as your application requirements, sample volume, viscosity, and desired emulsion or dispersion characteristics. Look for machines with variable speed control, different impeller or rotor-stator options for versatile mixing, and features such as temperature control or vacuum capability if needed. Additionally, consider the quality, reliability, and after-sales support provided by the manufacturer.

Model | LET-1L | LET-2L | LET-5L | LET-10L |

Power supply | 220V,50/60Hz | 220V,50/60Hz | 220V,50/60Hz | 220V,50/60Hz |

Minimum allowable mixing volume | 300ml | 500ml | 1000ml | 2500ml |

Minimum allowable amount of emulsification | 500ml | 1000ml | 2500ml | 5000ml |

The maximum allowable amount of emulsification | 1000ml | 2000ml | 5000ml | 10000ml |

Working temperature | 170℃ | 170℃ | 290℃ | 290℃ |

Can reach vacuum (Mpa) | -0.097~0.02 | -0.097~0.02 | -0.097~0.02 | -0.097~0.02 |

Maximum processing viscosity (CP) | 100,000 | 100,000 | 200,000 | 300,000 |

Stirring motor power | 90W | 120W | 150W | 180W |

Stirring speed range (rpm) | 0~230 | 0~230 | 0~230 | 0~230 |

Stirring paddle configuration | Anchor screw with scraping wall impeller | |||

Scraper material | Silicone Rubber | |||

Homogeneous motor power | 500W | 500W | 800W | 1050W |

Homogeneous speed range (rpm) | 10000~28000 | 10000~30000 | 10000~30000 | 10000~30000 |

Homogeneous working head configuration | 20DG | 25DG | 25DG | 30DG |

Reactor lid opening | Homogenizer port + hopper port + temperature measuring port + vacuum port + 3 spare ports | |||

Lifting bracket travel | 210 | 210 | 270 | 270 |

The main contact material with the material | SS316L, borosilicate glass, FKM10 | |||

Vacuum port outer diameter | 10 | 10 | 10 | 10 |

Inlet and outlet outer diameter of glass kettle jacket | 12 | 12 | 16 | 16 |

Allowable ambient temperature | 5~40℃ | 5~40℃ | 5~40℃ | 5~40℃ |

Allowable relative humidity | 80% | 80% | 80% | 80% |

Dimensions (mm) | 400*390*780 | 400*390*780 | 480*420*850 | 480*420*850 |

Standard weight (Kg) | 37 | 38 | 45 | 60 |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap