- +86 17324835373

- [email protected]

- 19/F, Block B, Guohong Mansion, Zhengzhou, Henan, China

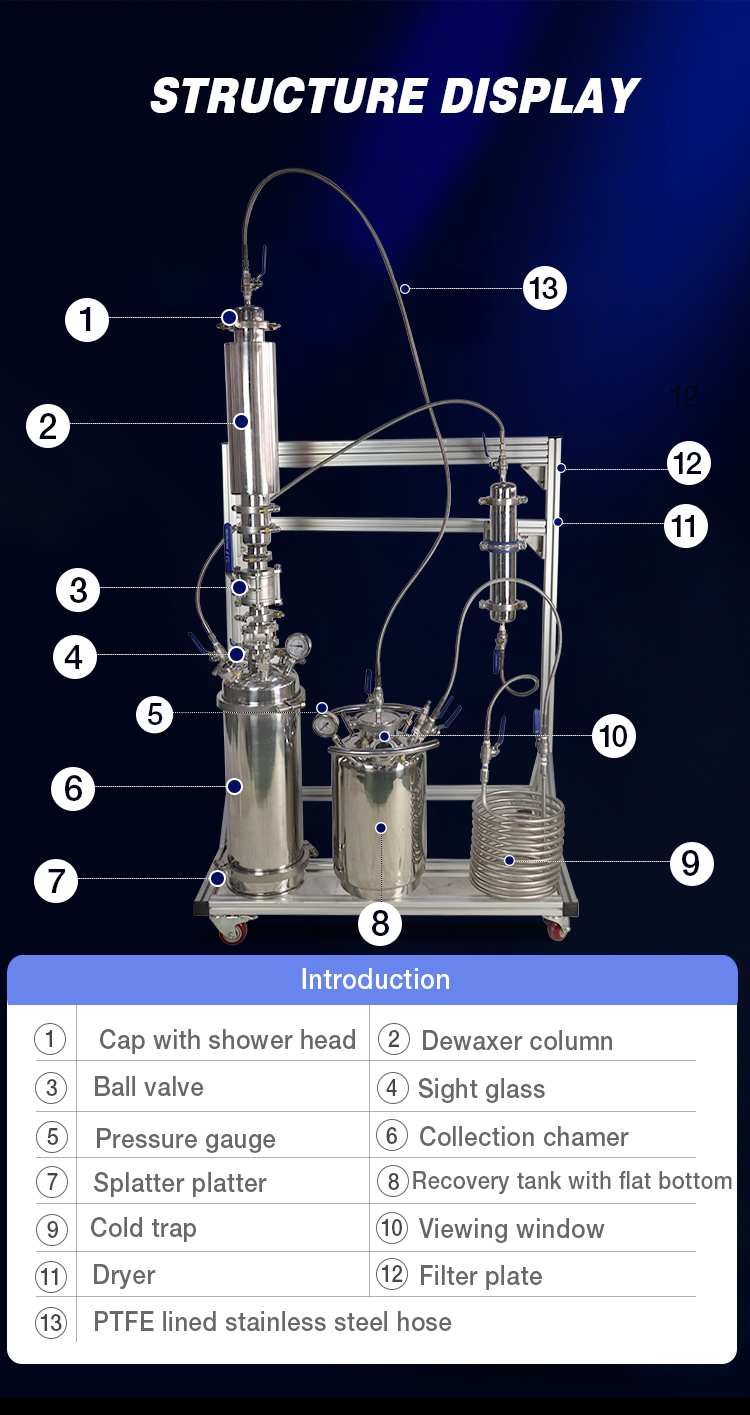

Advantage:

The closed loop extractor is a chemical extraction system used to make cannabis concentrate. The process of closed-loop extraction is to coat unprocessed cannabis plants in a pressurized solvent, expose them to high-pressure shocks, and reduce them to resins before processing them into the desired form of cannabis concentrate. These concentrates include active resins containing the most active terpenes and butane hash oil, which are usually further processed into products such as buds, crushed, wax and crushed products. After extraction, the resulting concentrate can be converted into different products, and the method used may vary from product to product. The concentration of THC concentrate in closed loop systems is usually very high, up to about 80-90%.

Features:

1. Made of stainless steel, not easy to rust, and long service life.

2. The PTFE lined hose has good airtightness and excellent chemical resistance.

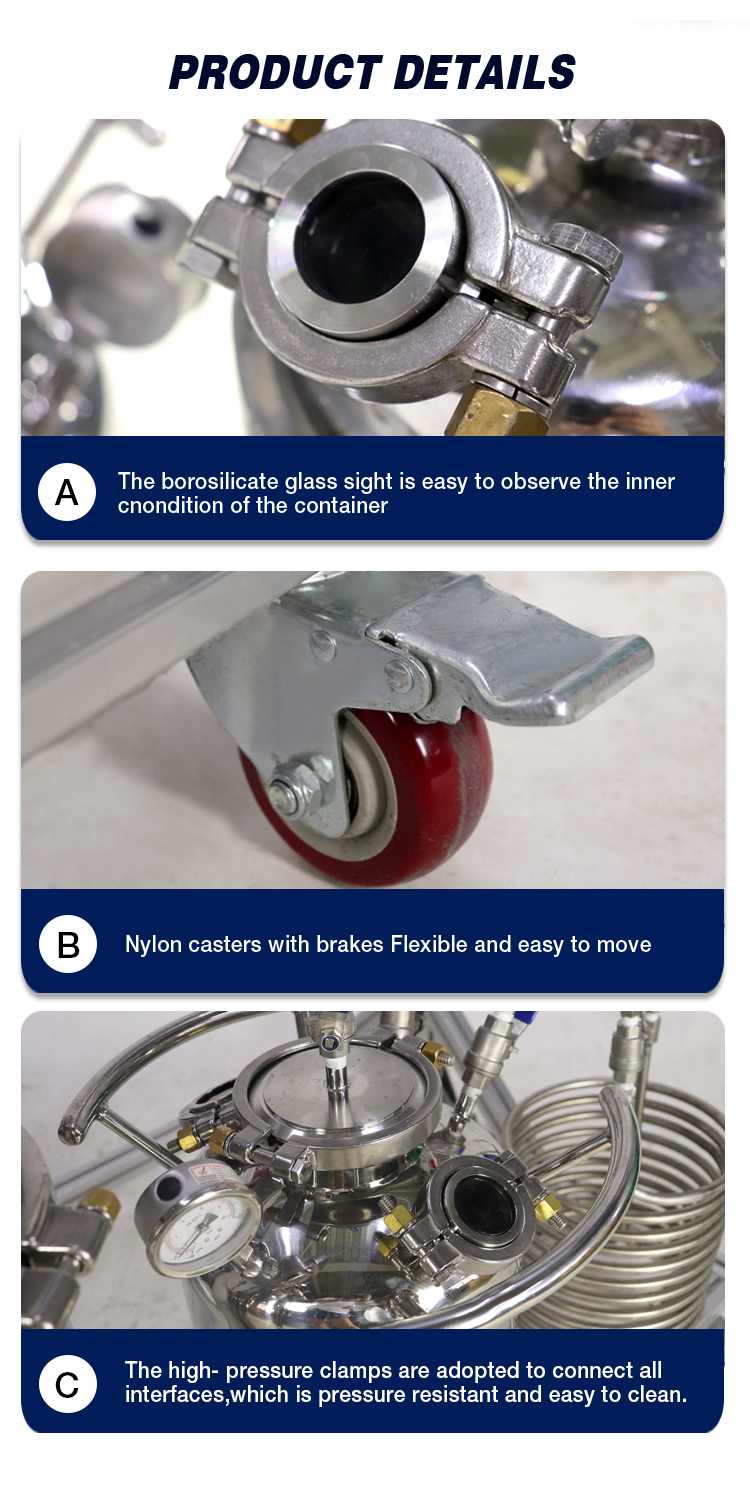

3. With casters, easy to move, small in size, suitable for various environments.

4. The extraction yield is higher, safer, and the extraction speed is faster.

5. With a vacuum pressure gauge, you can intuitively observe the vacuum degree of extraction.

6. Simple operation and energy saving.

7. The overall structure is precise, beautiful and reasonable in price.

8. The borosilicate glass window can easily observe the internal condition of the container.

FAQ:

1. What are the disadvantages of closed loop extractors?

Although the closed loop extractor minimizes the risk of explosion, it is still dangerous because the solvent used in the extraction process is highly flammable, so a fume hood should be used. The solvent used in this extraction system destroys plant tissues, cannabinoids and chlorophyll.

2. What are the advantages of the closed loop extractor?

The closed loop extraction system provides some of the highest quality products. The temperature and pressure balance present in the system is increased to produce a very pure, full-bodied and delicious concentrate. Compared with the open-loop extraction system, the closed-loop extraction process will not have any residue, because everything is sucked out from the vacuum, so a cleaner concentrate can be obtained.

3. In order to achieve closed-loop extraction, some equipment and devices are needed, which are very important for forming an efficient extraction system, including:

Pressurized solvent tank, pressurized pump, blasting chamber, collection chamber, vacuum furnace, recovery pump.

4. What are the main features of closed-loop extraction?

The main feature of the closed-loop extraction system is to separate air from the solvent during the extraction process, which is the difference between air and open-loop methods. The system consists of several specialized equipment such as solvent storage tanks, recovery tanks, scales and several pumps. The system includes continuous checking of pressure and valve operation, as well as allowing solvent reuse.

Although closed-loop extraction has been used for the production of perfumes, beauty products, food additives and other essential oils for many years, it has only recently been discovered that it is safer than open can shot blasting and closed-loop systems. Popular cannabis extraction method. Because it minimizes the risk of explosion and provides a safer way to use flammable solvents. The machine used for extraction has no openings, so it cannot safely contain solvents and does not allow gas to escape.

Although hemp concentrates have been around for some time, they are becoming increasingly popular in the United States. This is due to the legalization of marijuana in many states including Colorado and Washington, which can be obtained by using different extraction methods. These extraction methods usually use special solvents and extractants (such as propane, ice water, butane, etc.) to isolate some beneficial products from the triangle nematode in the cannabis plant. The extraction method of cannabis is different, and some major changes have taken place over time, until recently it was discovered that the closed-loop method is preferable to other methods.

Name | Closed loop extractor |

Material | SS304,SS316 |

Capacity | 1lb,2lb,5lb,10lb,80lb |

Surface treatment | Mirror polished |

Used | Beverage,beer,water treatment,comestic,pharmacy,etc |

Please leave your contact information, we will arrange the business staff to contact you as soon as we see the message.

Copyright © 2022. ZZKD machinery equipment co., LTD All rights Sitemap