What is freeze drying?

The Working Principle Of Freeze Dry

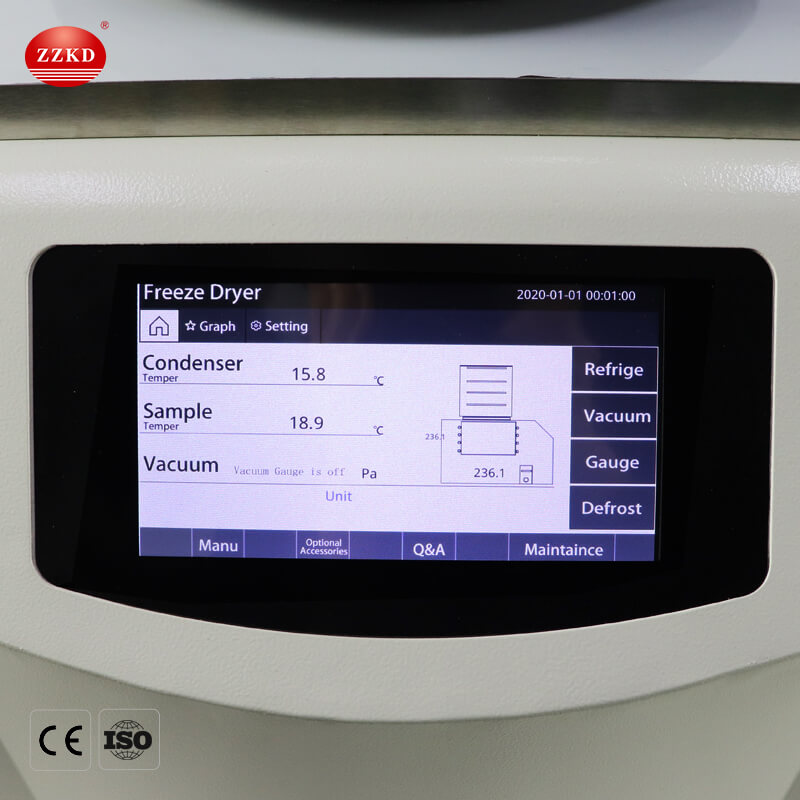

The laboratory freeze dryer is a way for drying by the precept of sublimation. It is a means of rapidly freezing the dried material at a low temperature after which immediately sublimating the frozen water molecules into water vapor in a correct vacuum setting.The superior touch freeze dryer supplier mannequin is for guide and computerized operation, with optimum control and regulation of temperature, stress and time, just like the contact mannequin.

It is critical to maintain the product temperature safely under this crucial temperature throughout major drying to keep away from collapse. The product temperature is dependant on the vapor strain on the ice interface and in flip, this vapor stress is dependant on each the rate of heat switch into the product and the system vacuum level set point. Freeze-drying is a method of eradicating water by sublimation of ice crystals from frozen materials.

To forestall the physical and chemical and organic denaturation of dry matter to the greatest extent. Secondary drying is sustained till the product has acceptable moisture content material for long term storage. Depending on the appliance, moisture content material in absolutely dried products is often between 0.5% and 3%. In most circumstances, the more dry the product, the longer its shelf life might be. However, certain complicated organic products may very well become too dry for optimum storage outcomes and the secondary drying course of must be controlled accordingly. Another tool is out there with freeze dryer designs which have external condensers.

Freeze drying is easier than canning or dehydrating, and can last as lengthy as eight times longer. In a couple of day, your meals is freeze-dried, packaged and prepared for a shelf-life of as a lot as 25 years. The unit has hermetically sealed compressor to take care of temp. Temperature management by digital controller cum indicator with electronic vacuum indicator.

This freezing technique maximizes the product floor space and minimizes its thickness. It is greatest to not freeze a big block of sample in the backside of a flask because the sample might be too thick for efficient water removal. Sublimation is a phase change and warmth vitality should be added to the frozen product for it to happen.

There are several advantages of having one of the best freeze dryers at home, offered that it suits your lifestyle and requirements perfectly. The measurement of this appliance is small, and thus it is simple for use and saved. There is plenty of room inside this appliance for making your creations. This equipment has the magical power of converting contemporary food into edible merchandise, which can be saved and consumed until 25 years.

So, choose the best freeze dryer that perfectly suits your requirements, and luxuriate in all the advantages mentioned above. After this, you can remove the food from the freeze dryer and place it in proper vacuum-sealed containers that are oxygen and moisture proof. This could be a vacuum can or a pouch which retains the freshness of the freeze dried meals till opened.

This is a premium freeze dryer that's constructed with a patented know-how to keep the merchandise contemporary and likewise preserve the overall potency, form, colour and vitamin of any edible organic materials. This appliance is largely useful within the freeze drying of the several oils, herbs, medicines, prescribed drugs, treatments and compounds. The freeze dryers are specifically designed for assembly analysis and development phase freeze drying necessities in the increasingly demanding in trade and academia. When investing in a meals freeze drying enterprise, you need to select food freeze drying tools not a pharmaceutical freeze drying gear. Industrial vacuum freeze dryer has glorious efficiency, which might make the water within the meals instantly elegant and dry from the stable beneath the situations of slurry and vacuum, without evaporation of the liquid. Large scale freeze dryer comes with quick freezer, trolley and rail for product pre-freezing and fast loading and unloading.

This equipment is ideal for freeze drying medicines, oils, herbs, compounds, pharmaceuticals and remedies. This appliance is large-sized and has 8 trays that present a complete tray area of 10.25 sq. The process of freeze drying by this machine preserves the overall dietary content material, appearance and efficiency of the products for a quantity of years, identical to they had when they were in their fresh state.

We can customise the capability and configurations of the BLK100kg freeze dryer. For buyers who want to produce freeze-dried food, one of the best freeze dryer is a meals freeze dryer. For firms that want to produce drugs, the most effective freeze dryer is a pharmaceutical freeze dryer. For universities, the best freeze dryer is the experimental freeze dryer. The most important factor is to choose the best freeze dryer producer. The freeze dryer is a professional machine, and the trade and distribution supplier can not fully perceive the freeze dryer technology.

Freeze Dryer Value, 2022 Freeze Dryer Value Producers & Suppliers

The main components of the freeze dryer are drying field, condenser, refrigeration unit, vacuum pump, heating/cooling device, and so forth. As the product dries from high to backside, the resistance to ice sublimation gradually will increase. In order to make sure the whole sublimation of the entire field of products, the plate temperature nonetheless needs to be maintained for one stage earlier than the second stage of temperature improve.

The freeze dryer unit and the superior-quality vacuum pump that's seated outside the primary unit are the two components of a freeze dryer. Once the meals are frozen, the freeze dryer appliance would create a vacuum throughout the food chamber. A freeze dryer at all times helps in preserving highest quality of foods, herbs and different organic supplies for a fairly very long time. The facility of 4-liter ice condensing capacity may be very useful. There are certain superior options like the log of the temperature and strain during all parts of the freeze dry cycle.

In addition to its wide utility in the fields of medicine, organic products, meals, blood merchandise and energetic substances, its utility scale and subject Still expanding. To this end, vacuum freeze drying is bound to turn into an essential software technology in the twenty first century. Critical Collapse Temperature – this is the most necessary piece of knowledge for cycle optimization. The capability to run major drying at larger product temperatures tremendously reduces drying time by creating a larger stress differential between the vapor pressure over ice within the product and the pressure at the condenser. Each 1oC increase in product temperature can lower main drying time by 13%. Freeze drying is a expertise that makes use of the precept of sublimation to dry.

You can even use it to protect fresh foods and even leftovers to reduce back wastage. This freeze dryer is perfect for meals storage as a end result of it retains nearly all the unique vitamins not like dehydrating, canning, and freezing. The technology has additionally been improved to completely automate the freeze drying process.

There aren't any large freeze-drying equipment producers in the United States, and solely pharmaceutical freeze-drying tools producers in Europe, and large-scale vacuum freeze-drying tools for food manufacturing. Our merchandise are widely used in the handling of meals, flowers, medicine, bio-products, and chemical substances. The design, structure, manufacturing, installation, and testing of our freeze dryers are carried out independently by our employees. We make investments heavily in our R&D division, permitting for improvements within the design of our freeze dryers and supplying much wanted sources for choices.