What Is a Rotovap

rotovap machines, colloquially known as rotovaps, stand as indispensable tools in modern laboratories and industrial settings, revolutionizing solvent removal processes across diverse applications.

rotovap machines are sophisticated instruments designed to facilitate the efficient removal of solvents from liquid samples through evaporation under reduced pressure. These devices harness the principle that solvents possess varying boiling points, which decrease under reduced pressure, enabling rapid and controlled evaporation.

The key component of a rotovap machine is the evaporation flask, which rotates at a specified speed to create a thin film of the sample along the inner surface of the flask. This increased surface area facilitates evaporation, leading to the efficient removal of solvents while preserving the desired compounds or substances.

Rotovap machines find applications across a wide spectrum of industries, including pharmaceuticals, chemistry, biotechnology, and materials science. They are utilized for concentration, crystallization, drying, separation, and solvent recovery, making them indispensable tools for researchers, scientists, and engineers.

Operating Principles of Rotovap Machines

Rotovap machines operate on the principle of reducing the pressure in the system, thereby lowering the boiling points of the solvents present in the sample. As the evaporation flask rotates, the sample forms a thin film along the inner wall, maximizing the surface area available for evaporation.

The flask is heated evenly to facilitate solvent evaporation, while a condenser cools the vapor, causing it to condense and collect in a separate receiving flask. This process allows for the efficient recovery of solvents while preserving the integrity of the sample.

Industry |

Materials Used |

Rotovap Machine Model |

Parameters |

Pharmaceutical |

Active pharmaceutical ingredients, solvents |

RE-301 |

Rotating Motor: 40W, Water Bath Power: 1500W, Temperature Control Range: RT to 399°C, Evaporation Rate: ≥1.5L/h, Voltage: 220V, Lifting Height: 0-120mm |

Chemical |

Solvents, reaction mixtures |

RE-5002 |

Rotating Motor: 250W, Water Bath Power: 7000/9000W, Temperature Control Range: RT to 99(250)°C, Evaporation Rate: >9L/h, Voltage: 380V, Lifting Height: 0-220mm |

Food and Beverage |

Flavor compounds, extracts, distillates |

RE-2000B |

Rotating Motor: 40W, Water Bath Power: 1500W, Temperature Control Range: RT to 99°C, Evaporation Rate: ≥1L/h, Voltage: 220V, Lifting Height: 0-140mm |

Environmental |

Volatile compound analysis, sample preparation |

RE-201D |

Rotating Motor: 40W, Water Bath Power: 1200W, Temperature Control Range: RT to 399°C, Evaporation Rate: ≥1L/h, Voltage: 220V, Lifting Height: 0-150mm |

Research |

Synthesis of compounds, purification |

RE-1002 |

Rotating Motor: 180W, Water Bath Power: 3000W, Temperature Control Range: RT to 99(250)°C, Evaporation Rate: >3L/h, Voltage: 220V, Lifting Height: 0-220mm |

Cannabis |

Cannabinoid and terpene extraction |

RE-2002 |

Rotating Motor: 180W, Water Bath Power: 5000W, Temperature Control Range: RT to 99(250)°C, Evaporation Rate: >5L/h, Voltage: 220V, Lifting Height: 0-220mm |

Different Models of Rotovap For Sale

Considerations:

1. Operators must undergo thorough training on the operation and safety procedures for the specific Rotovap machine model.

2. Strictly follow safety protocols provided in the manual for each machine model.

3. Regularly inspect and maintain the Rotovap machine to ensure it operates within specified parameters.

4. Utilize appropriate personal protective equipment, including goggles, gloves, and lab coats, when handling materials.

5. Work with volatile or hazardous materials in a well-ventilated area or under a fume hood.

6. Adhere to proper waste disposal procedures in accordance with regulations.

7. Monitor process parameters, such as temperature and rotation speed, to prevent accidents and ensure efficient operation.

Benefits of Using Rotovap Machines

Rotovap machines offer several advantages over traditional evaporation methods conducted under atmospheric pressure. These include:

1. Efficiency: rotovap machines enable faster and more efficient solvent removal, leading to increased productivity in laboratory settings.

2. Precision: The controlled evaporation process of rotovap machines allows for precise control over parameters such as temperature, pressure, and rotation speed, ensuring reproducible results.

3. Versatility: rotovap machines can be used for a wide range of applications, from simple solvent removal to complex processes such as crystallization and distillation.

4. Ease of Use: Despite their advanced capabilities, rotovap machines are relatively simple to operate and can be found in laboratories of all sizes.

Factors to Consider When Selecting a Rotovap Machine

Several factors should be taken into account when selecting a rotovap machine for a particular application:

1. Solvent Type: Understanding the properties of the solvent is crucial for selecting the appropriate rotovap machine, as different solvents have varying boiling points and evaporation characteristics.

2. Heating and Cooling Capacity: The heating and cooling capacity of the rotovap machine must match the requirements of the application to ensure efficient solvent removal and condensation.

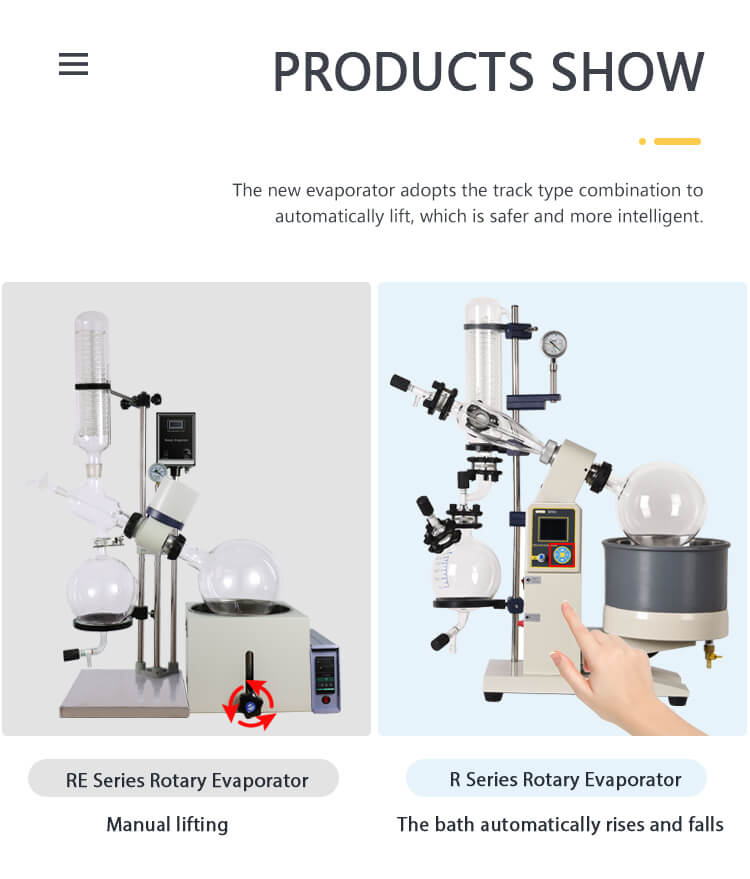

3. Automation and Accessories: Features such as motorized lifts and automatic boiling point detection can streamline operations and minimize manual intervention, enhancing productivity and efficiency.

4. Size and Configuration: rotovap machines come in various sizes and configurations to accommodate different volumes and sample types. Benchtop models are ideal for smaller laboratories, while larger-scale units are suitable for industrial applications.

Model |

Water(Oil) Bath Power(W) |

Temperature Control Range |

Evaporation Rate(H2O) |

Lifing Height(mm) |

RE-2000B |

1500 |

RT~99℃ |

≥1L/h |

0~140 |

RE-5299 |

1500 |

RT~99℃ |

≥1L/h |

0~150 |

RE-201D |

1200 |

RT~399℃ |

≥1L/h |

0~150 |

RE-301 |

1500 |

RT~399℃ |

≥1.5L/h |

0~120 |

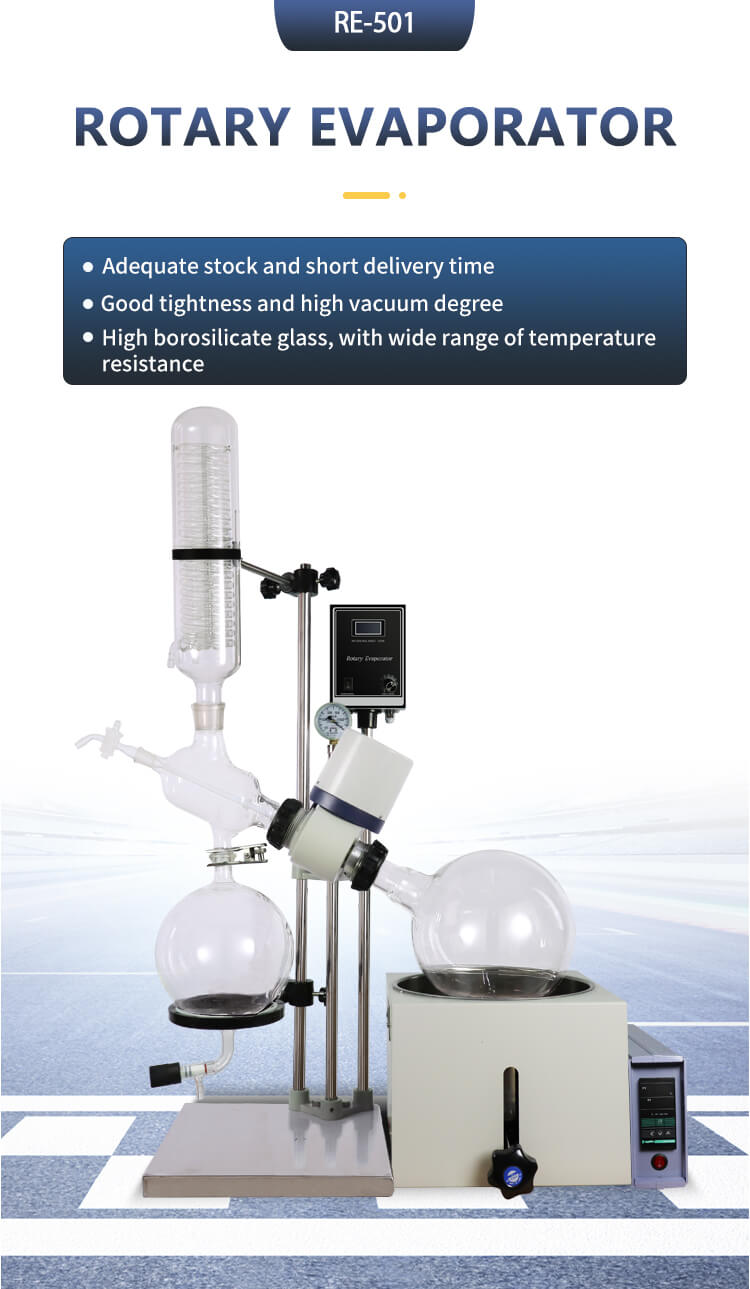

RE-501 |

1500 |

RT~399℃ |

≥1.5L/h |

0~120 |

RE-1002 |

3000 |

RT~99(250)℃ |

>3L/h |

0~220 |

RE-2002 |

5000 |

RT~99(250)℃ |

>5L/h |

0~220 |

RE-5002 |

7000/9000 |

RT~99(250)℃ |

>9L/h |

0~220 |

RE-2000B |

1500 |

RT~99(250)℃ |

≥1 |

0-140 |

EXRE-1002 |

3000 |

RT~99(250)℃ |

>3 |

/ |

EXRE-2002 |

5000 |

RT~99(250)℃ |

>5 |

/ |

EXRE-5002 |

7000/9000 |

RT~99(250)℃ |

>9 |

/ |

Rotovap machines come in a diverse range of sizes and configurations tailored to meet a wide spectrum of application requirements. Compact benchtop models like the RE-2000B and RE-5299 are specifically designed for space-constrained laboratories. These units feature powerful rotating motors and water or oil baths capable of reaching temperatures from room temperature to 99°C, offering an evaporation rate of at least 1L/h for water. They also boast digital controls with temperature accuracy of ±1°C and adjustable lifting heights ranging from 0 to 140 mm or 150 mm, depending on the model.

On the other hand, larger-scale rotovap machines such as the RE-1002, RE-2002, and RE-5002 are tailored for expanded applications. These models are equipped with more robust rotating motors and higher-capacity water or oil baths, enabling them to achieve temperatures of up to 250°C. Moreover, they offer evaporation rates exceeding 3L/h, 5L/h, and 9L/h respectively, making them suitable for applications requiring larger evaporation volumes.

These rotovap machines can be seamlessly integrated with a variety of accessories and automation features to optimize workflow efficiency and meet the diverse needs of modern scientific endeavors.

Our flagship Rotovap machine brings revolutionary solutions to your doorstep. Whether you're in a research laboratory or on the production line, our Rotovap machine offers efficient, reliable distillation, and concentration solutions. With impeccable engineering, outstanding performance, and dependable operation, it enhances your workflow with unparalleled convenience and efficiency. If you're interested in our Rotovap machine, contact us now to embark on your journey of innovation!

Conclusion

Rotovap machines represent a groundbreaking technology in solvent removal processes, offering unparalleled efficiency, precision, and versatility across a wide range of applications. With their ability to rapidly and effectively remove solvents while preserving the integrity of the sample, rotovap machines have become indispensable tools for researchers, scientists, and engineers seeking to advance their work in chemistry, pharmaceuticals, biotechnology, and beyond. As technology continues to evolve, rotovap machines will undoubtedly remain at the forefront of innovation in solvent removal and sample preparation methodologies.